Carbon stick processing machine set

A technology of unit and carbon rod, which is applied in the direction of presses, manufacturing tools, etc., can solve environmental pollution and other problems, and achieve the effect of solving environmental pollution problems, solving environmental pollution, and low humidity requirements for raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

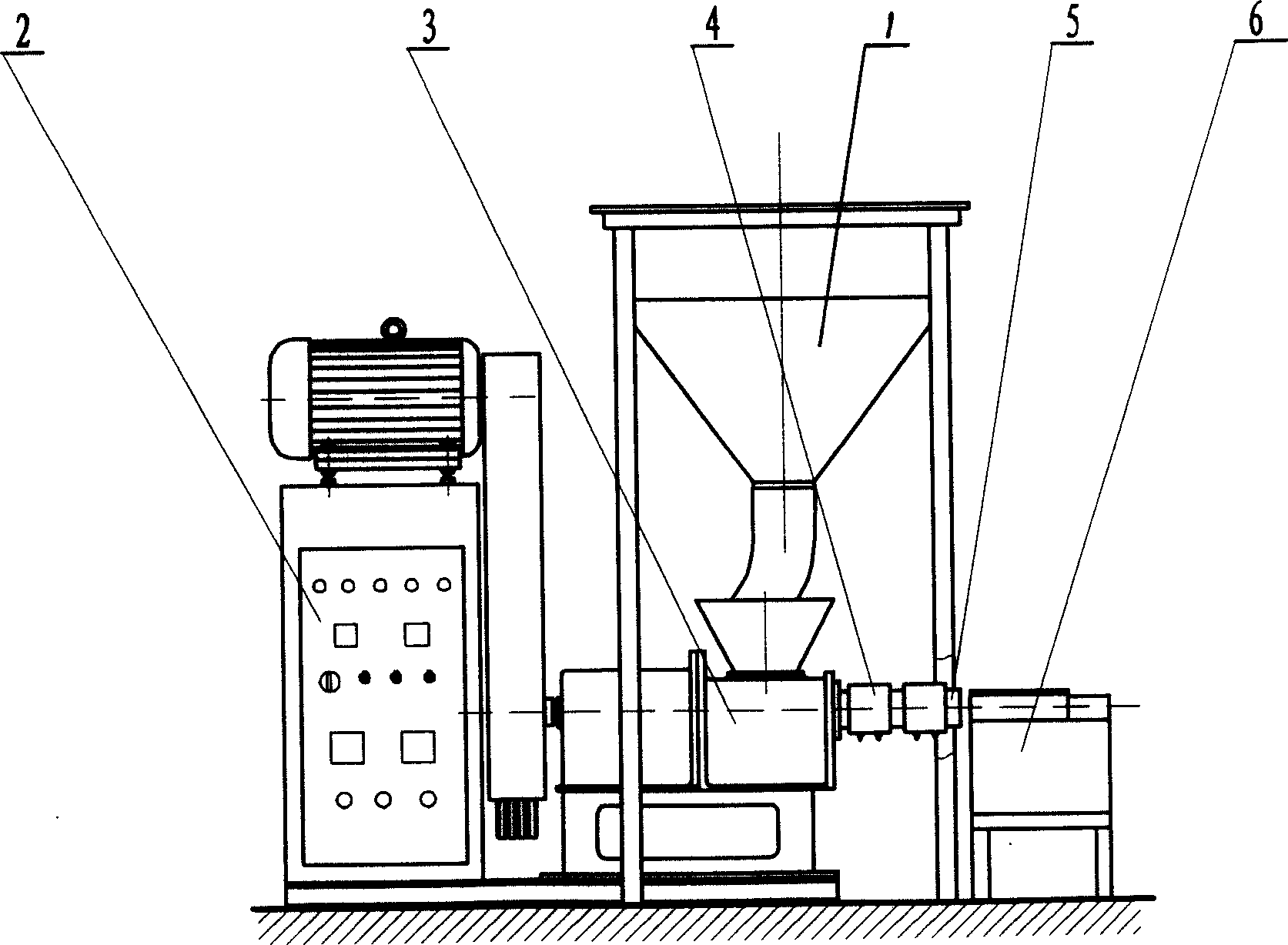

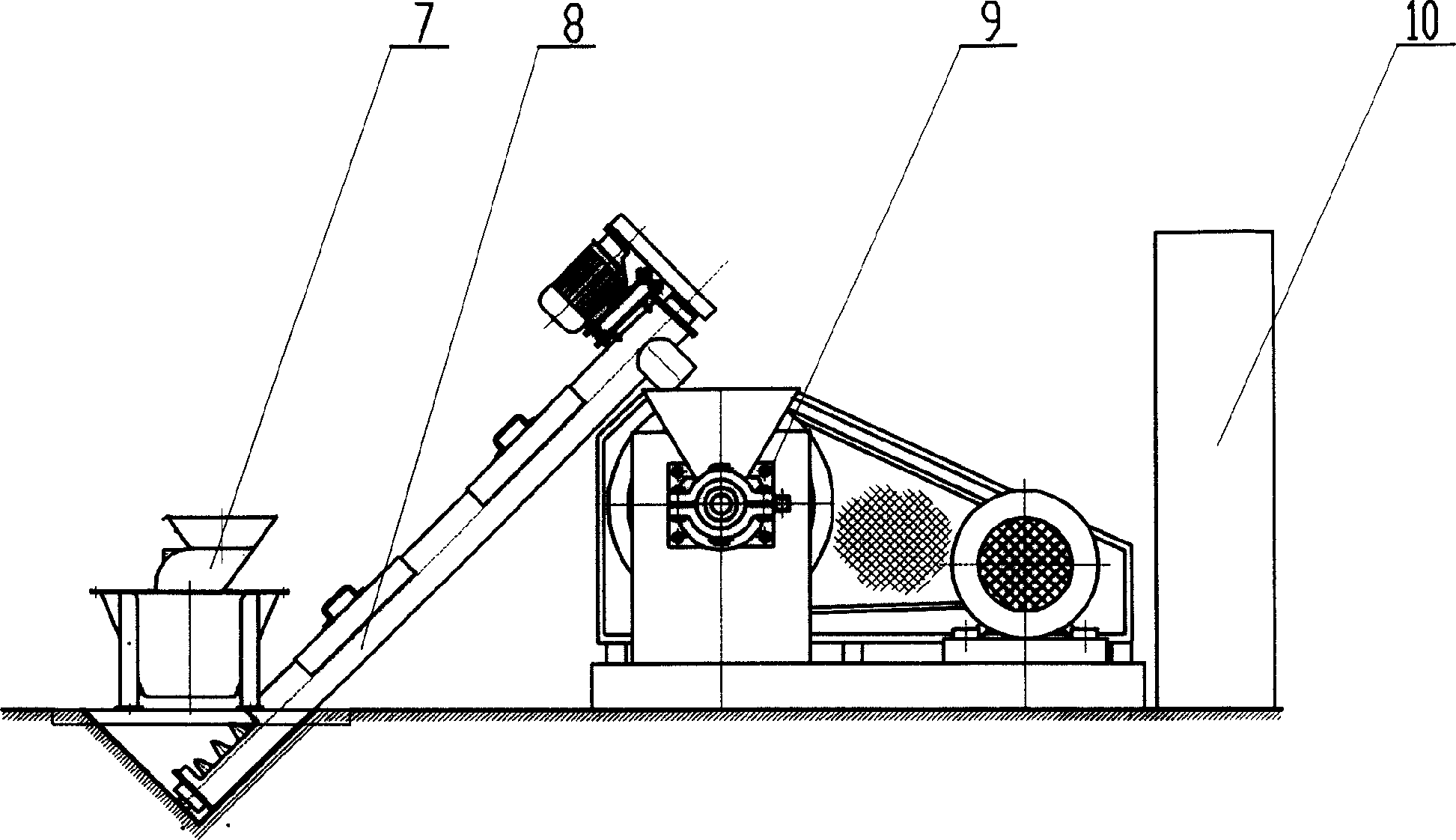

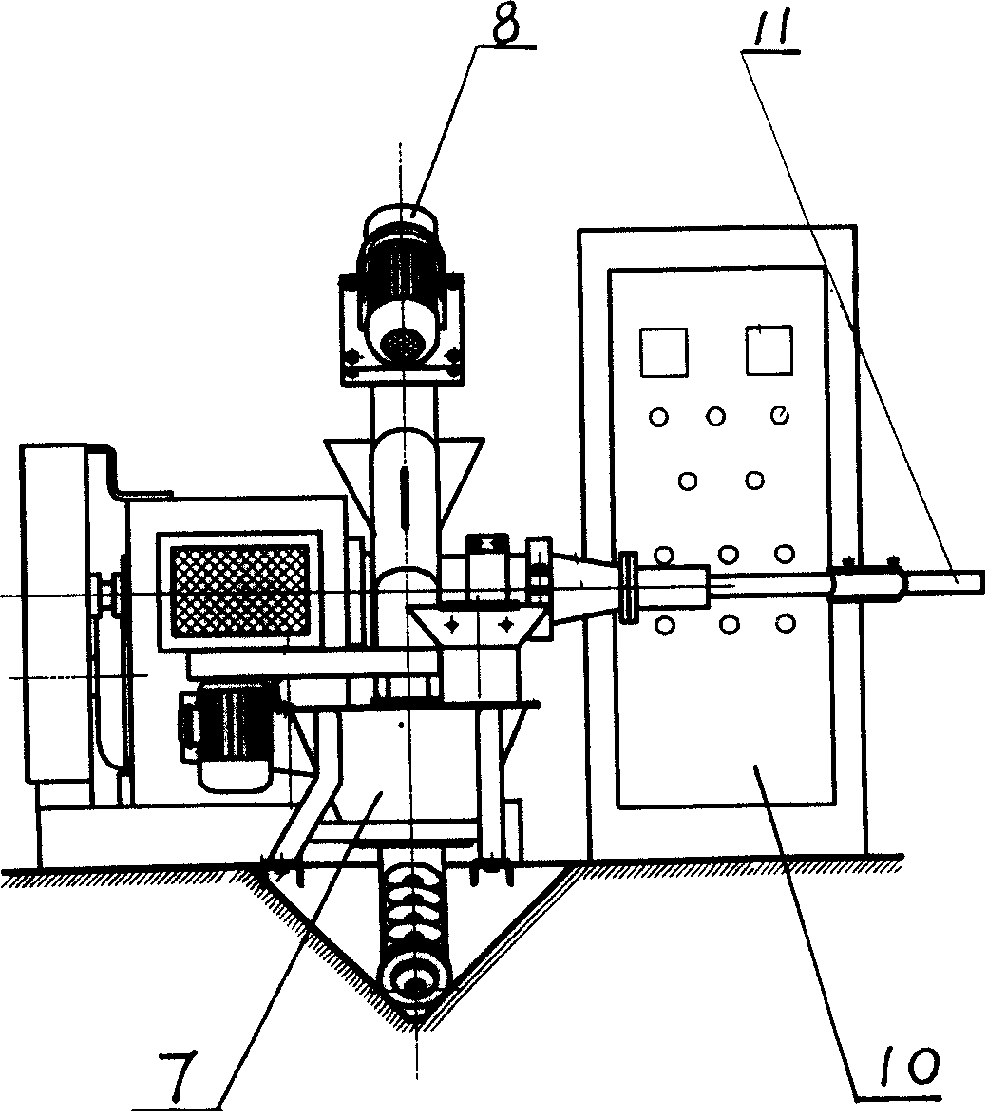

[0036] Such as figure 2 , 3 Shown is a schematic structural diagram of a carbon rod processing unit. The carbon rod processing unit is composed of a crusher 7, a feeding auger 8, a rod extruder 9, an electrical control box 10, and a rod breaking device 11.

[0037] Such as Figure 4 , 5 , 6, which is a structural schematic diagram of a crushing machine, the crushing machine 7 is composed of a motor 12, a protective cover 13, a V-belt 14, a hopper 15, a frame 16, a cover plate 17, a material adjustment plate 18, and a hammer Crushing box 19, belt pulley 20, belt knife main shaft 22, bearing 21, fixed hammer 23 are formed, and motor 12 is installed on one side of frame 16, and V-belt 14 connects motor 12 and pulley 20, and pulley 20 is connected by bearing 21. At the end of the vertical knife main shaft 22 in the middle of the crushing box 19, the protective cover 13 is placed outside the V-belt 14, and the feeding hopper 15 is located at the upper end of the crushing box 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com