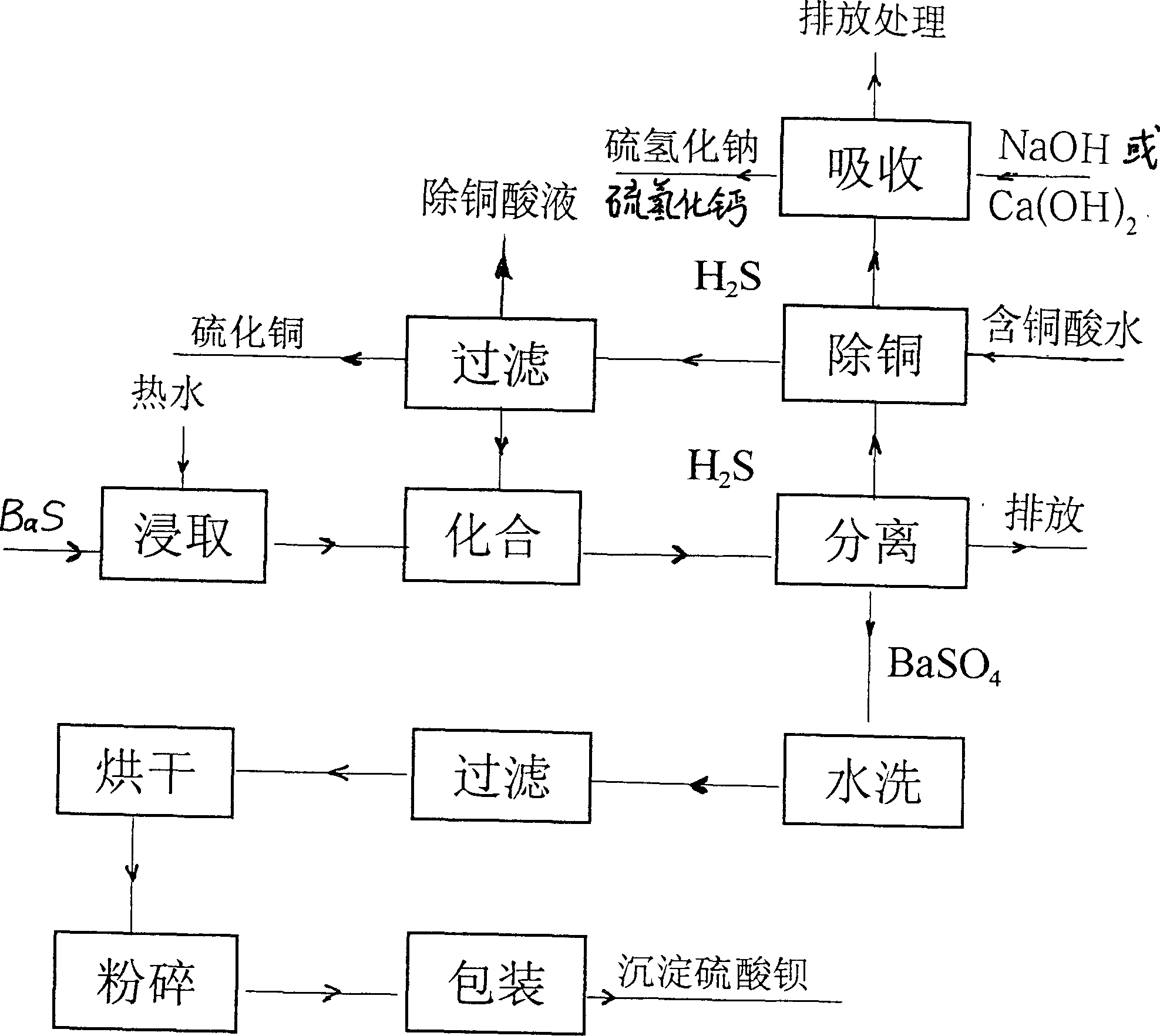

Method for treating copper-containing waste acid water

A treatment method and technology for waste acid water, which are applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problems, to achieve the effect of improving the utilization rate, protecting the environment, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 3.5T of clear water into the leaching kettle, heat to 100°C, turn on the exhaust or vacuum, stir, and slowly add 1.2T of powdered barium sulfide with a content of 60%; continue to heat to 100°C, keep stirring for 30 minutes, and make the The concentration of the liquid taken is not lower than 15Be`; open the valve at the bottom of the kettle, pump it into the plate and frame filter press for filtration, remove the solid phase impurities and filter residue to the waste yard for centralized treatment; the treated filter residue can be used to produce cement or produce wall tiles Raw materials; the filtrate is introduced into the storage tank for standby. When filtering and leaching the barium sulfide solution, if barium sulfide is precipitated, the filter residue should be leached again with 100°C water.

[0031] Take the pretreated copper removal acid solution 5T and place it in an acid-resistant reaction kettle, turn on the induced wind or vacuum, stir, and slowly a...

Embodiment 2

[0035] Place 30% sulfuric acid solution in the acid-resistant reactor, then slowly add the barium sulfide leaching solution, and add lime water to make the absorbent in the absorption liquid circulation tank, and the others are the same as in Example 1 to obtain the calcium hydrosulfide finished product. The resulting finished product is analyzed and measured by the method specified in the relevant regulations, and meets the requirements of the method standards specified in the relevant regulations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com