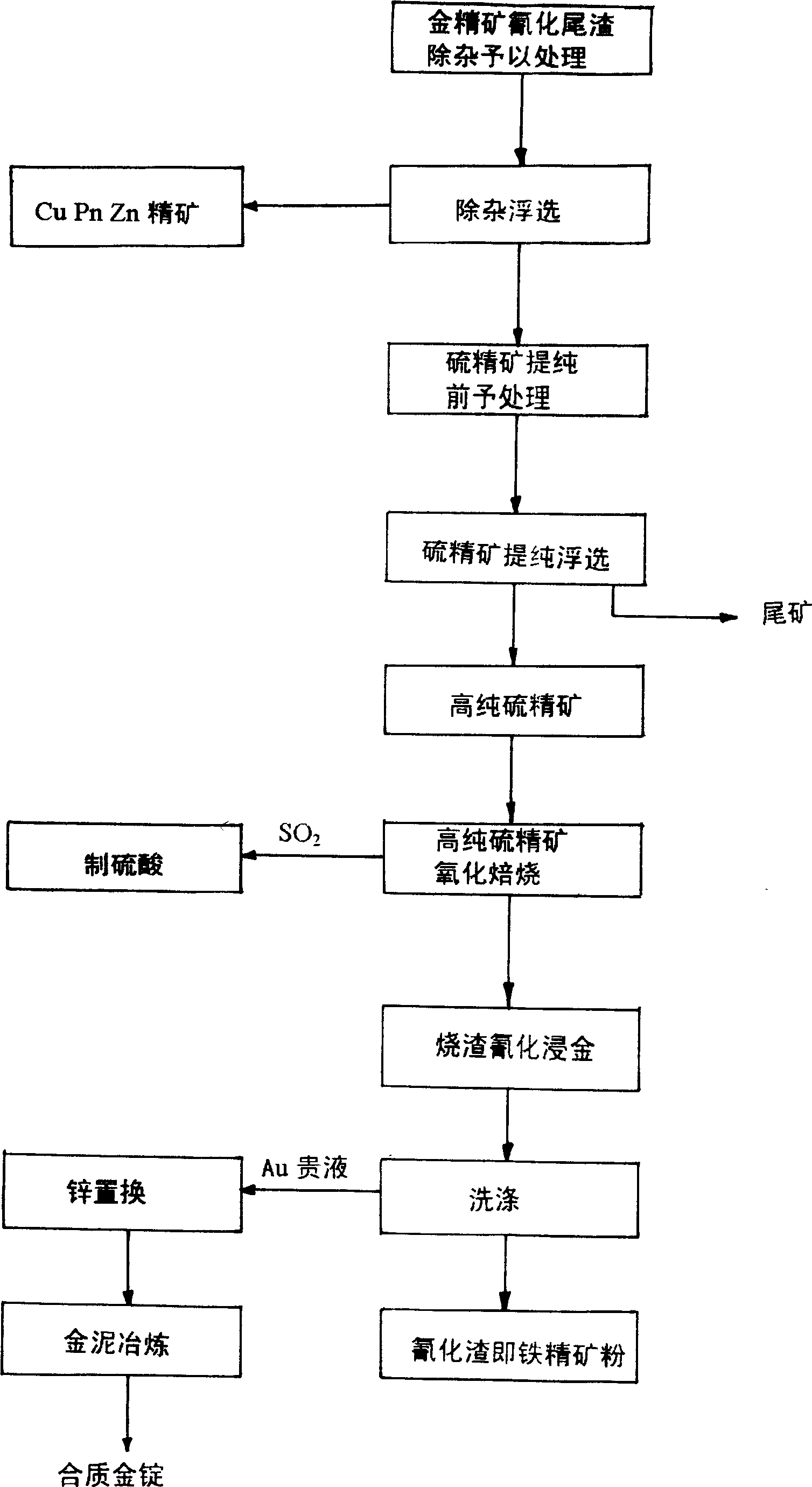

Sulfogen ore impurity-removing, purifying and flotation process

A sulfur concentrate and flotation technology, which is applied in flotation, solid separation, etc., can solve the problems of low utilization rate of cinder iron, poor economic benefits, and low technical indicators, and achieve good economic benefits, wide application range, and technical The effect of high index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1. Pulp pretreatment:

[0065] a) Get a certain amount of gold concentrate cyanidation tailings filter cake to be removed, put it into a stirring tank and add water to adjust the slurry, so that the concentration of the slurry is adjusted to C=60%;

[0066] b) Add concentrated sulfuric acid to the pulp in the stirring tank, stir the pulp while adding sulfuric acid, make the PH=4~7 of the pulp, and stir for 10 minutes;

[0067] c) Move the activated pulp to the next stirring tank, add water to the stirring tank, and dilute the pulp until the flotation concentration C=28-33%;

[0068] d) Add fluttering agent, namely butyl xanthate and butyl ammonium black medicine, to the mixing tank with adjusted slurry concentration, foaming agent 2 # Appropriate amount of oil, stirring for 2 to 5 minutes, the pulp enters the flotation tank for flotation to remove impurities;

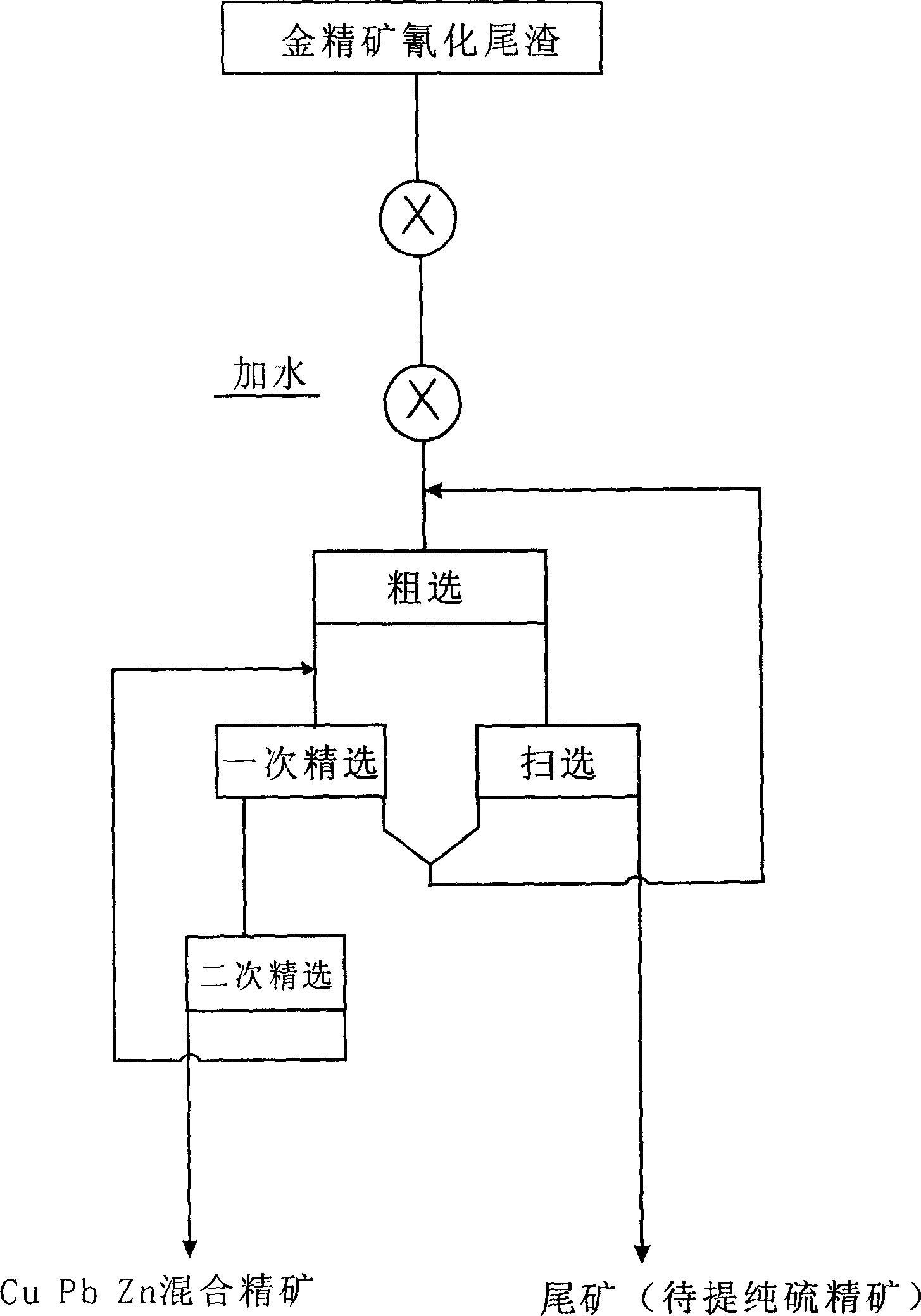

[0069] 2. Impurity removal flotation:

[0070] a) rough selection:

[0071] After pretreatment and ...

Embodiment 2

[0081] 1. Pretreatment of the pulp to be removed:

[0082] a) Get a certain amount of gold concentrate cyanidation tailings filter cake to be removed, put it into a stirring tank and add water to adjust the slurry, so that the slurry degree is adjusted to C=60%;

[0083] b) Add concentrated sulfuric acid to the pulp in the stirring tank, stir the pulp while adding sulfuric acid, make the PH=4~7 of the pulp, and stir for 10 minutes;

[0084] c) Move the activated pulp to the next stirring tank, add water to the stirring tank, and dilute the pulp until the flotation concentration C=28-33%;

[0085] d) Add fluttering agent, namely butyl xanthate and butyl ammonium black medicine, to the mixing tank with adjusted slurry concentration, foaming agent 2 # Appropriate amount of oil, stirring for 2 to 5 minutes, the pulp enters the flotation tank for flotation to remove impurities;

[0086] 2. Impurity removal flotation:

[0087] a) rough selection:

[0088] After pretreatme...

Embodiment 3

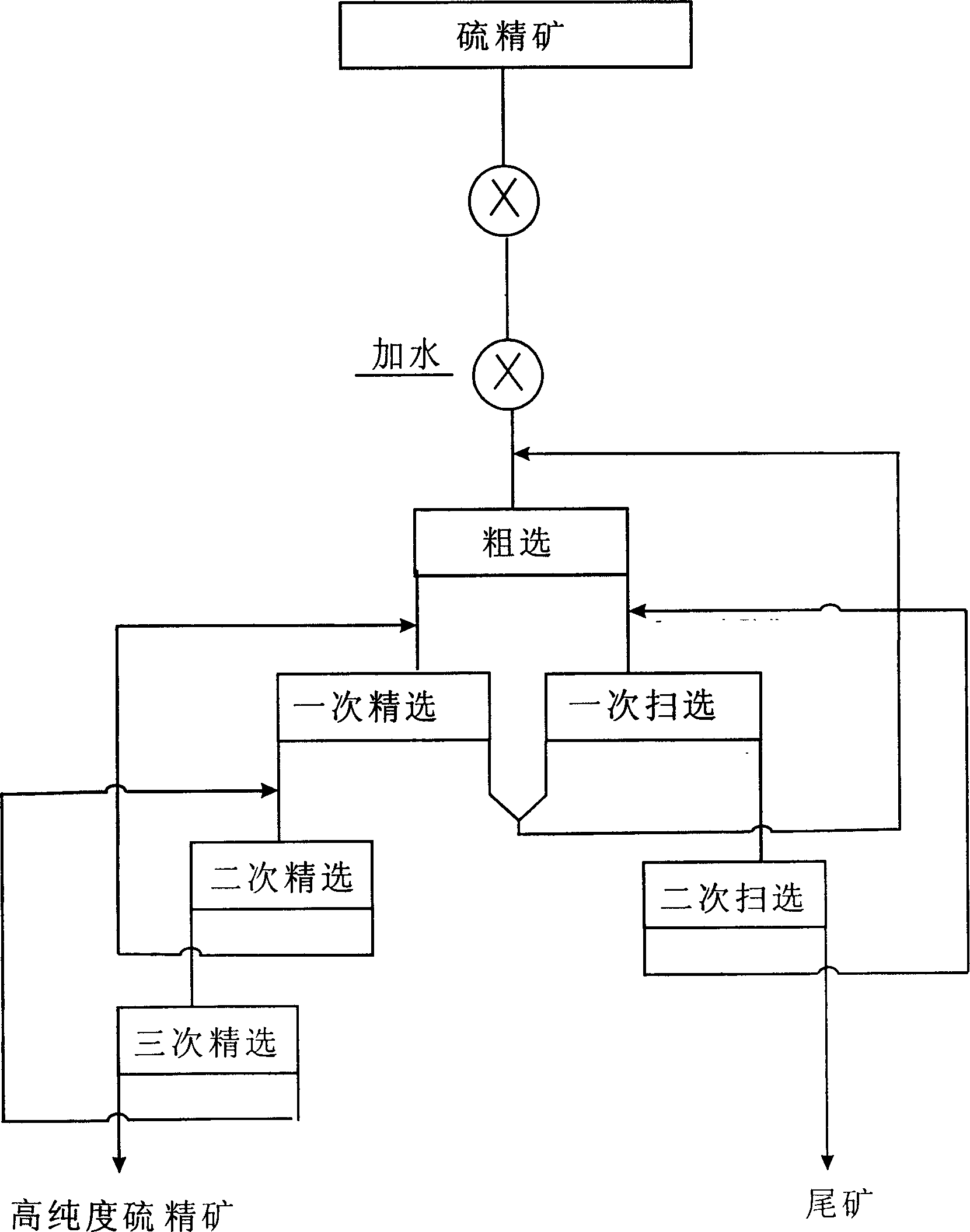

[0096] as attached figure 2 Shown, is the sulfur concentrate purification flotation process flow chart of the present invention,

[0097] the element

[0098] 1. Pulp pretreatment:

[0099] a) Sulfur concentrate to be purified is adjusted in a stirring tank, so that the concentration of the slurry is adjusted to C=60%;

[0100] b) Add concentrated sulfuric acid to the slurry in the stirring tank, and stir the slurry while adding sulfuric acid, so that the PH of the slurry=1~4;

[0101] c) Stir for 10 minutes after the PH value of the slurry is stabilized at a certain value to activate pyrite and inhibit quartz;

[0102] d) Move the activated pulp to the next stirring tank, add water to dilute the pulp concentration to flotation concentration C=28~33%;

[0103] e) Add flotation agent butylammonium black medicine and 2 to the diluted pulp # Appropriate amount of oil, stir for 2-5 minutes;

[0104] 2. Sulfur concentrate purification flotation:

[0105] a) Rough s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com