Gemini boric acid ester glucose acylamine compound, and its preparing method and use

A technology of glucosamide and compounds, which is applied in the field of borate glucosamide compounds, and can solve problems such as inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 Synthesis of Gemini borate n-hexyl glucamide compound

[0054] (1) Synthesis of n-hexylglucosamide

[0055] Add 2.65ml (0.02mol) of n-hexylamine, 2.85g (0.016mol) of D-glucono-δ-lactone, and 30ml of methanol into a 50ml three-necked flask equipped with a spherical condenser and a thermometer, and then control the temperature in an oil bath at 40°C , magnetically stirred, δ-lactone dissolved after 10 minutes, and a white solid appeared after 30 minutes. Keep this temperature for half an hour, then raise the temperature to 50°C, the solid dissolves again, and it will slowly precipitate when the temperature is lower than 49°C Solid, keep warm at 50°C for 3 hours to obtain a transparent solution, stop heating, stand still, gradually precipitate white crystals, and obtain white crystals by suction filtration. Yield 92.9%.

[0056] The reaction equation is as follows:

[0057]

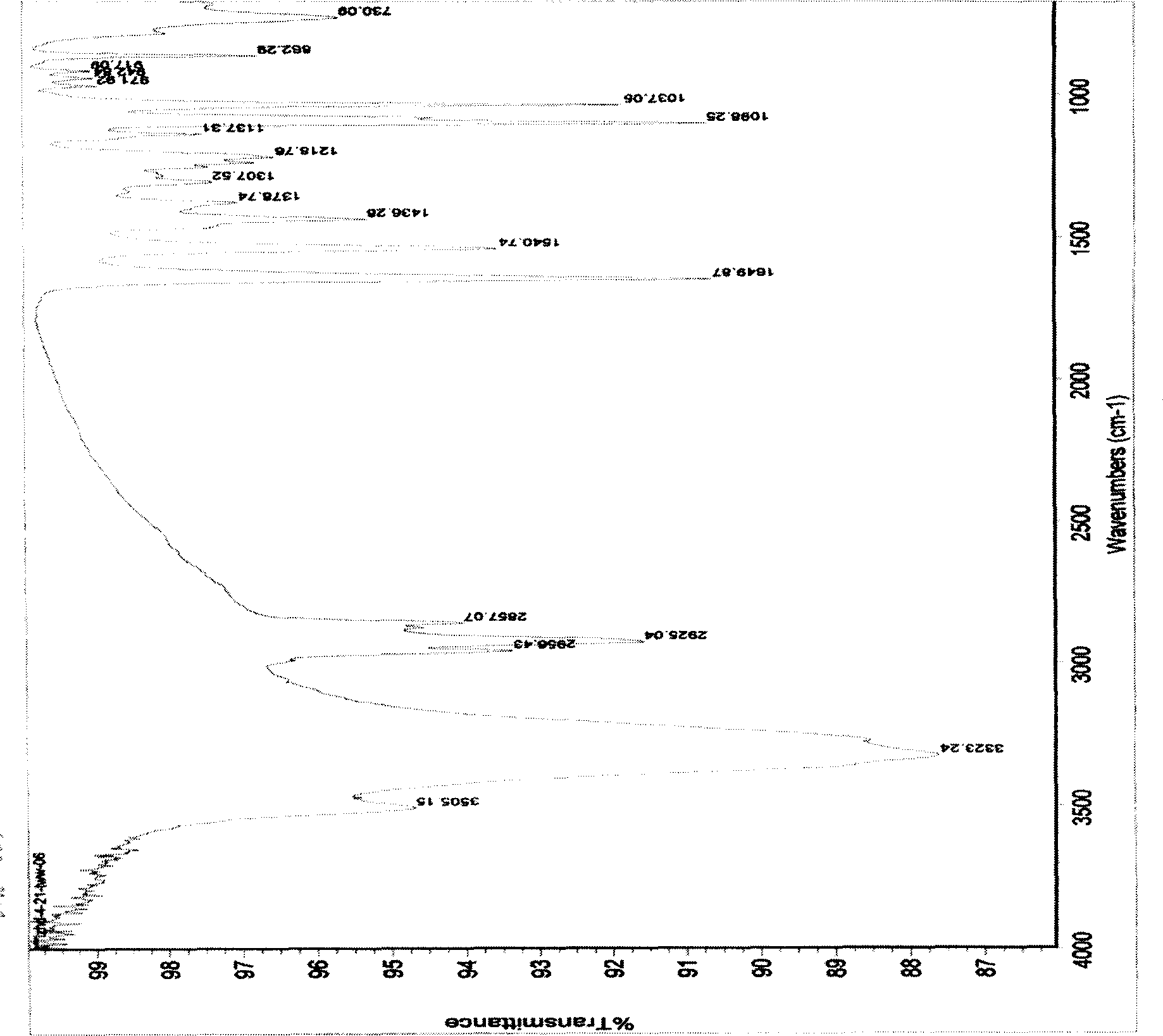

[0058] From figure 1 As shown in the infrared spectrum, it can be seen that at...

Embodiment 2

[0066] Example 2 Synthesis of Gemini borate n-octylglucosamide compound

[0067] (1) Synthesis of n-octylglucosamide

[0068] Add 3.31ml (0.02mol) of n-octylamine, 2.85g (0.016mol) of D-glucono-δ-lactone, and 30ml of methanol into a 50ml three-necked flask equipped with a spherical condenser and a thermometer, and then control the temperature in an oil bath for 40 ℃, magnetic stirring, D-glucono-δ-lactone dissolved after 10 minutes, white solid appeared again after 30 minutes, kept at this temperature for half an hour, then raised to 55℃, the solid dissolved again, kept at this temperature for 3 hours , to obtain a transparent solution, stop heating, stand still, gradually precipitate white crystals, and obtain white crystals by suction filtration, with a yield of 92.3%.

[0069] (2) Synthesis of Gemini borate n-octylglucosamide compound

[0070] Add 6.75g (0.022mol) of n-octylglucosamide, 0.62g (0.01mol) of boric acid, and 30ml of benzene into a three-necked flask equipped ...

Embodiment 3

[0073] Embodiment 3 Synthesis of Gemini borate dodecylglucosamide compound

[0074] (1) Synthesis of dodecylglucosamide

[0075]Add 2.85g (0.016mol) of D-glucono-δ-lactone, 0.018mol of dodecylamine into a 100ml three-necked flask, the molar ratio is 1:1.125, and 25ml of methanol, and then the oil bath is heated to 60°C. It was in a turbid state and dissolved after 10 minutes. After 2.5 hours, the solution produced an increase in solids. At this time, glucose amide had been generated. Then, 20ml of methanol was added to the system to continue the reaction for 2 hours to fully carry out the reaction, and a bright white turbid solution was obtained. The system was suction filtered to obtain a bright white solid, and then the solid was washed three times with distilled water to remove excess dodecylamine (because the product was insoluble in water at room temperature), and then the white solid was recrystallized by heating with distilled water, and the When boiling, the white sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com