Low loss solar heat-collecting tube

The invention relates to a solar collector tube and a technology for a collector tube, which is applied in the field of solar collector tubes, and can solve the problems of increasing the cost of the collector tube, large heat radiation loss, etc., and achieve the effects of low cost, high collector efficiency, and expanded application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

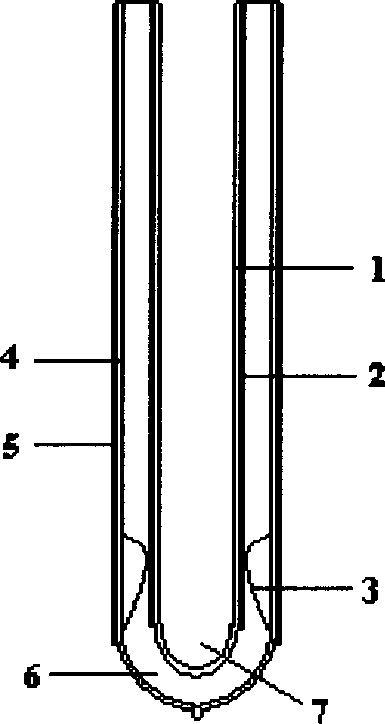

[0012] Such as figure 1 As shown, the present invention consists of a glass inner tube 1, a heat collecting tube absorbing layer 2 coated on the glass inner tube, a glass outer tube 4, a support spring 3 positioned between the heat collecting tube absorbing layer and the glass outer tube, and having spectrally selective transmission. The transparent conductive film with high performance or the plastic film 5 coated with the transparent conductive film layer, the transparent conductive film with spectral selective transmission ability is indium tin oxide, aluminum-doped zinc oxide, lanthanum hexaboride or cadmium stannate film .

[0013] The plastic film 5 plated with the transparent conductive film layer can first plate a transparent conductive film with spectrally selective transmission ability on a transparent plastic substrate, such as PVC, and then wrap this composite film on the glass outer tube 4 of the heat collecting tube. surface. figure 1 Among them, 6 is the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com