Electromagnetic-shielding light diffusion sheet

A technology of electromagnetic shielding and light diffusion, which is applied in the field of light diffusion plates, can solve the problems of inability to show electromagnetic shielding performance, darkening of liquid crystal displays, and decrease of total light transmittance, and achieve improved opacification characteristics and reduced linear expansion coefficient. The effect of small, elastic modulus increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

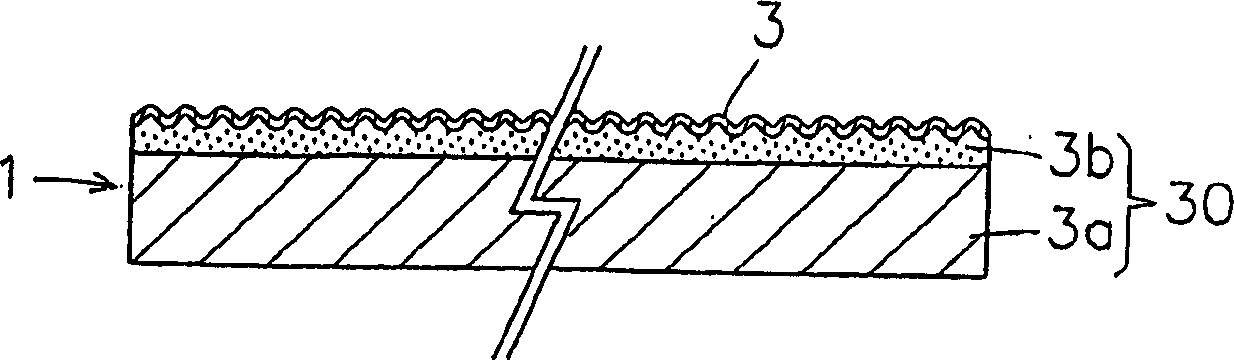

[0127] The polypropylene used as a light diffusing agent is extrusion molded into a single-layer board with a thickness of 130 μm to form the main body of the light diffusing board. The polypropylene contains 30% talc particles by mass and has an average particle size of 7.2 μm. .

[0128] On the other hand, single-walled carbon nanotubes (synthesized by the method according to ChemicalPhysics Letters, 323 (2000) pages 580-585; diameter 1.3-1.8nm) as a dispersant and polyethylene oxide / polypropylene oxide copolymer are added Into a mixture of isopropanol / water (3:1 ratio) as the solvent. The components are uniformly mixed and dispersed. Thus, a coating liquid was prepared, which contained 0.003% and 0.05% by mass of single-walled carbon nanotubes and a dispersant, respectively.

[0129] The coating liquid is applied to one side of the light diffusion plate main body and dried. After that, a thermosetting urethane acrylate solution diluted to 1 / 600 with methyl isobutyl ketone was f...

example 2

[0138] An electromagnetic shielding light diffusion plate was formed in the same manner as in Example 1, except that the content of talc particles as a light diffusion agent was changed to 25% by mass. In the same manner as in Example 1, the total light transmittance, blurriness, brightness, arithmetic average roughness of the upper and lower sides, surface resistivity, and dot coverage of the light diffusion plate were checked. The results are shown in Table 1. Regarding the electromagnetic shielding properties of the light diffusion plate, inspection can be omitted because its surface resistivity is almost the same as in Example 1, and it is considered that the light diffusion plate has almost the same performance as the electromagnetic shielding light diffusion plate of Example 1.

example 3

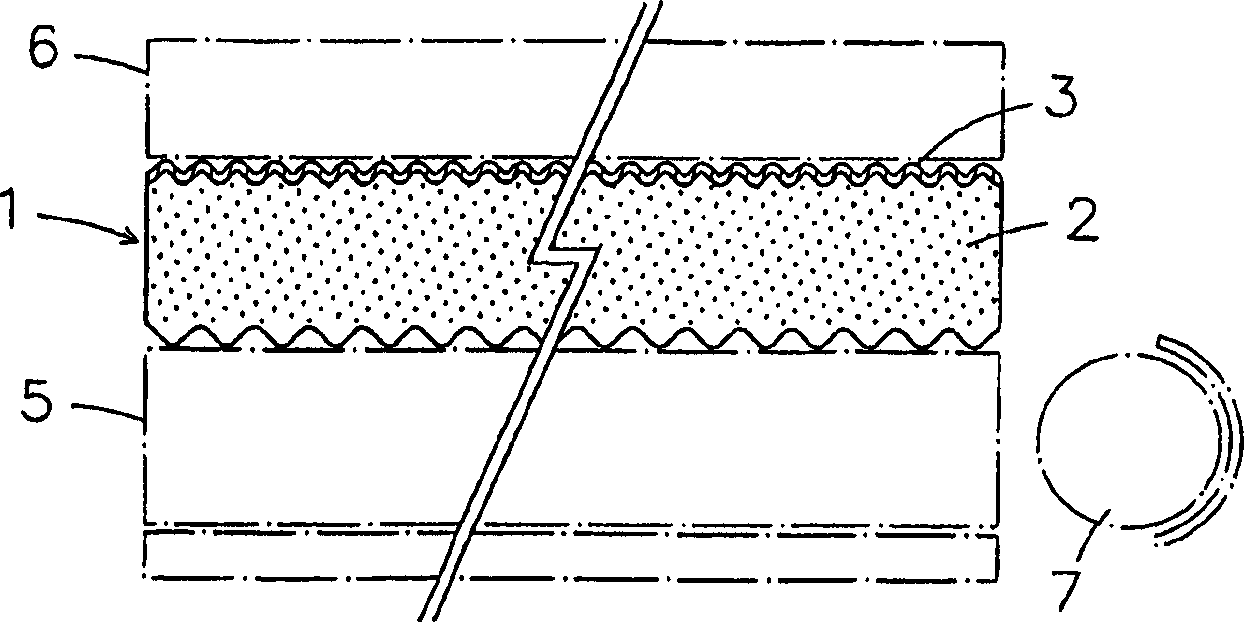

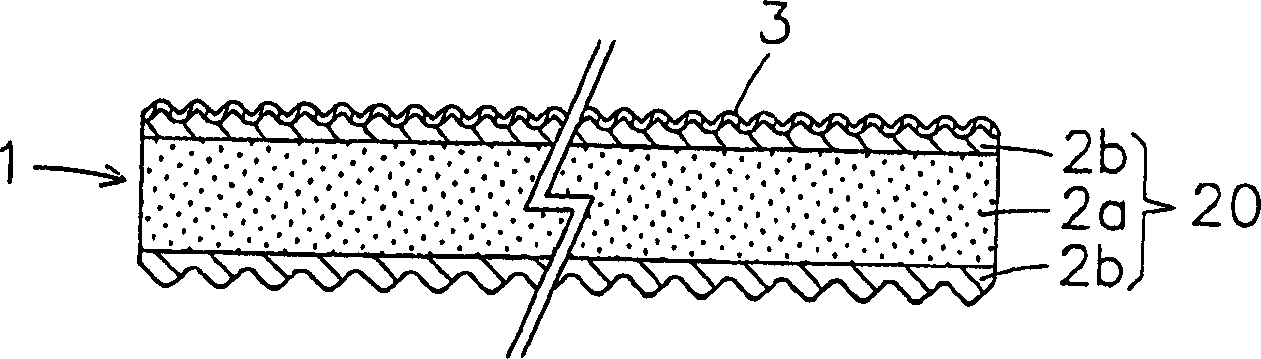

[0140] Obtained in the same way as in Example 1 figure 2 The electromagnetic shielding light diffusion plate of the structure shown, except that the polypropylene containing 21% talc particles by mass is extruded into a plate with a thickness of 112 μm by using a three-layer co-extrusion molding machine, and at the same time, it does not contain talc particles. Co-extruded polypropylene with a thickness of 130 μm to form a light-diffusing plate body composed of a three-layer plate with a thickness of 130 μm, so that a 9 μm-thick polypropylene plate is stacked on the upper and lower sides of the aforementioned plate.

[0141] In the same manner as in Example 1, the total light transmittance, blurriness, brightness, arithmetic average roughness of the upper and lower sides, surface resistivity, and dot coverage of the light diffusion plate were checked. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com