Preparation method of patterned titanium dioxide micro structure

A technology of titanium dioxide and microstructure, applied in the direction of titanium dioxide, replication/marking methods, titanium oxide/hydroxide, etc., can solve the problems of low selectivity of self-assembled membranes, reduce experimental costs, etc., and achieve improved clarity and boundary resolution High efficiency, easy mass production, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

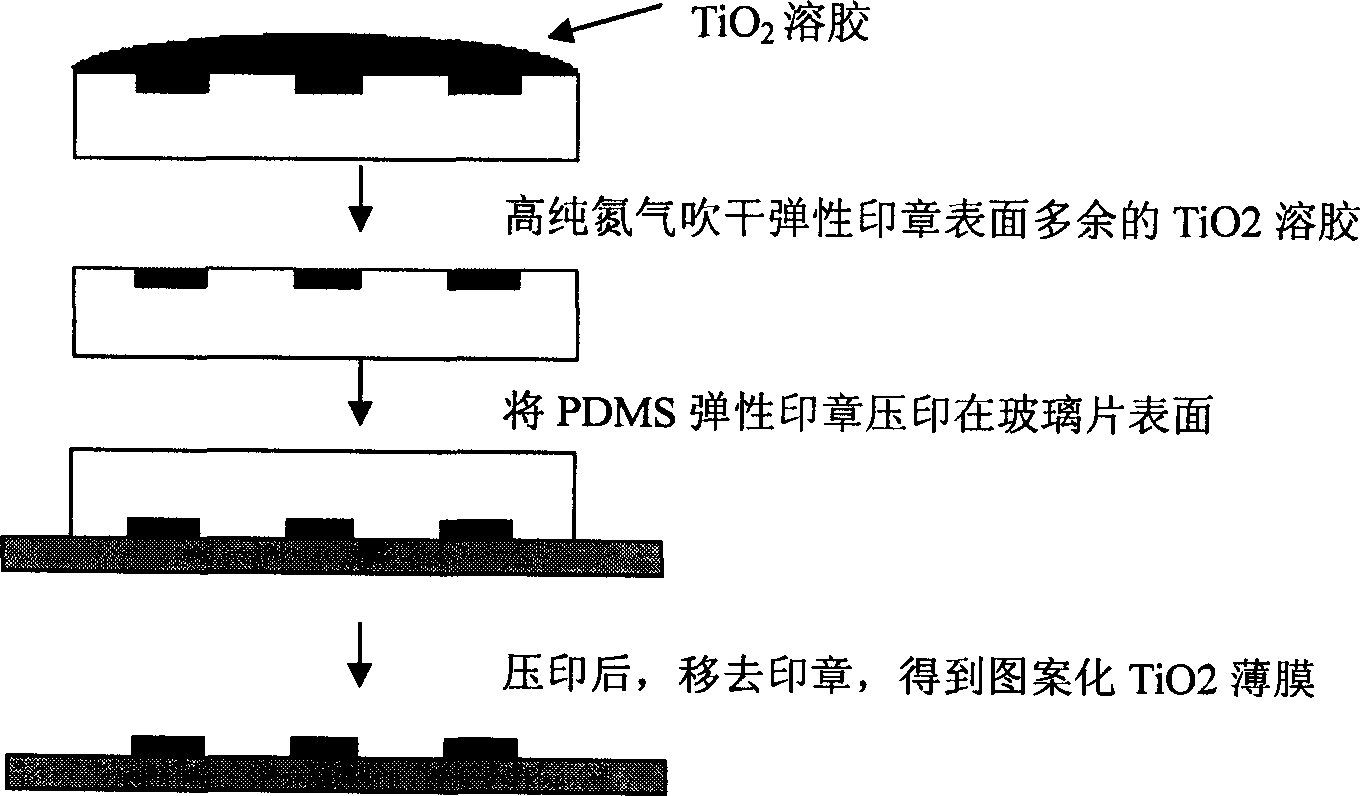

[0016] Fabrication of patterned titania microstructures on ordinary glass slides:

[0017] 1. Pretreatment of slides

[0018] Ordinary glass slides were cut into appropriate sizes and heat-treated with a mixed solution of concentrated sulfuric acid and hydrogen peroxide (Piranha solution) at 90°C for one hour.

[0019] 2. Preparation of Patterned Elastic Stamps

[0020] Polydimethylsiloxane (Sylgard 184 Dow Corning Company) was poured on the patterned surface of the micro-processed single crystal silicon membrane plate, cured at 150° C. for one hour, and aged and peeled off to obtain a silicone rubber elastic stamp with micropatterns.

[0021] 3. Preparation of titania sol

[0022] Butyl titanate [Ti(OBu) 4 ] as the raw material, accurately measure a certain amount of butyl titanate and dissolve it in absolute ethanol, the volume is two-thirds of the required volume, and add acetylacetone (AcAc) as an inhibitor. Then, under vigorous stirring, a mixed solution of nitric aci...

Embodiment 2

[0029] Fabrication of patterned titania microstructures on single crystal silicon wafers:

[0030] 1. Pretreatment of monocrystalline silicon wafers

[0031] Cut the monocrystalline silicon wafers into appropriate sizes and heat-treat them with a mixed solution of concentrated sulfuric acid and hydrogen peroxide (Piranha solution) at 100°C for one and a half hours.

[0032] 2. Preparation of Patterned Elastic Stamps

[0033] Polydimethylsiloxane (Sylgard 184 Dow Corning Company) was poured on the patterned surface of the micro-processed single crystal silicon membrane plate, cured at 150° C. for one hour, and aged and peeled off to obtain a silicone rubber elastic stamp with micropatterns.

[0034] 3. Preparation of titania sol

[0035] Butyl titanate [Ti(OBu) 4 ] as the raw material, accurately measure a certain amount of butyl titanate and dissolve it in absolute ethanol, the volume is two-thirds of the required volume, and add acetylacetone (AcAc) as an inhibitor. Then,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com