Preparation method of CoSb3 pyroelectric material having nanometer/micron composite crystal structure

A thermoelectric material and composite crystal technology, applied in the field of thermoelectric material manufacturing, can solve problems such as low thermal conductivity, complicated process, and decreased electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

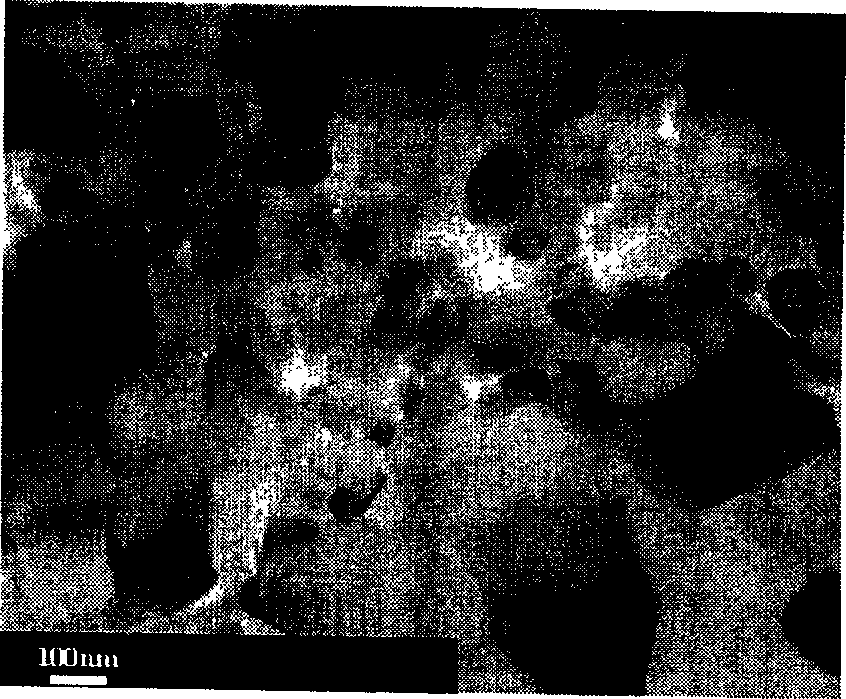

[0013] Example 1: Using metallic cobalt (80nm) and antimony (20μm) elemental powder as raw materials, according to CoSb 3 The chemical formula of the compound weighs the ingredients, and the powder is ground and mixed under the protection of argon, and then put into a graphite mold for SPS in-situ reaction synthesis. The sintering conditions are: pressure 30MPa, heating rate 120°C / min, temperature 450°C, holding time 3min. Obtain CoSb with nano / micro composite grain structure 3 Dense bulk material, its organization structure is like figure 1 As shown, the relative density is 93.0%. This material achieved a maximum ZT value of 0.34 at 700K.

example 2

[0014] Example 2: Using metallic cobalt (100nm) and antimony (40μm) elemental powder as raw materials, according to CoSb 3 The chemical formula of the compound weighs the ingredients, and the powder is ground and mixed under the protection of argon, and then put into a graphite mold for SPS in-situ reaction synthesis. The sintering conditions are: pressure 40MPa, heating rate 130°C / min, temperature 500°C, holding time 4min. Obtain CoSb with nano / micro composite grain structure 3 The dense bulk material has a relative density of 95.3%. This material achieved a maximum ZT value of 0.34 at 700K.

example 3

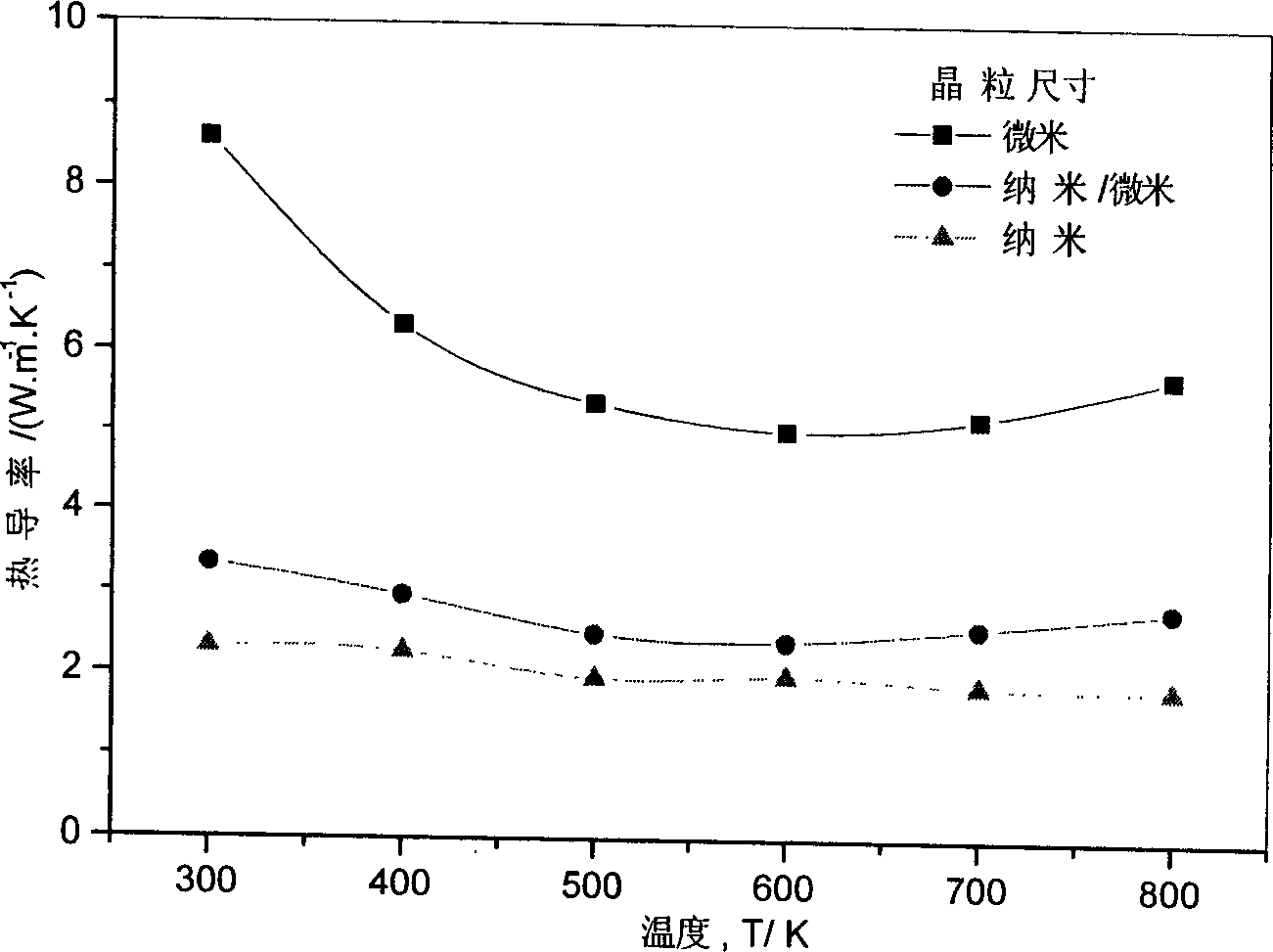

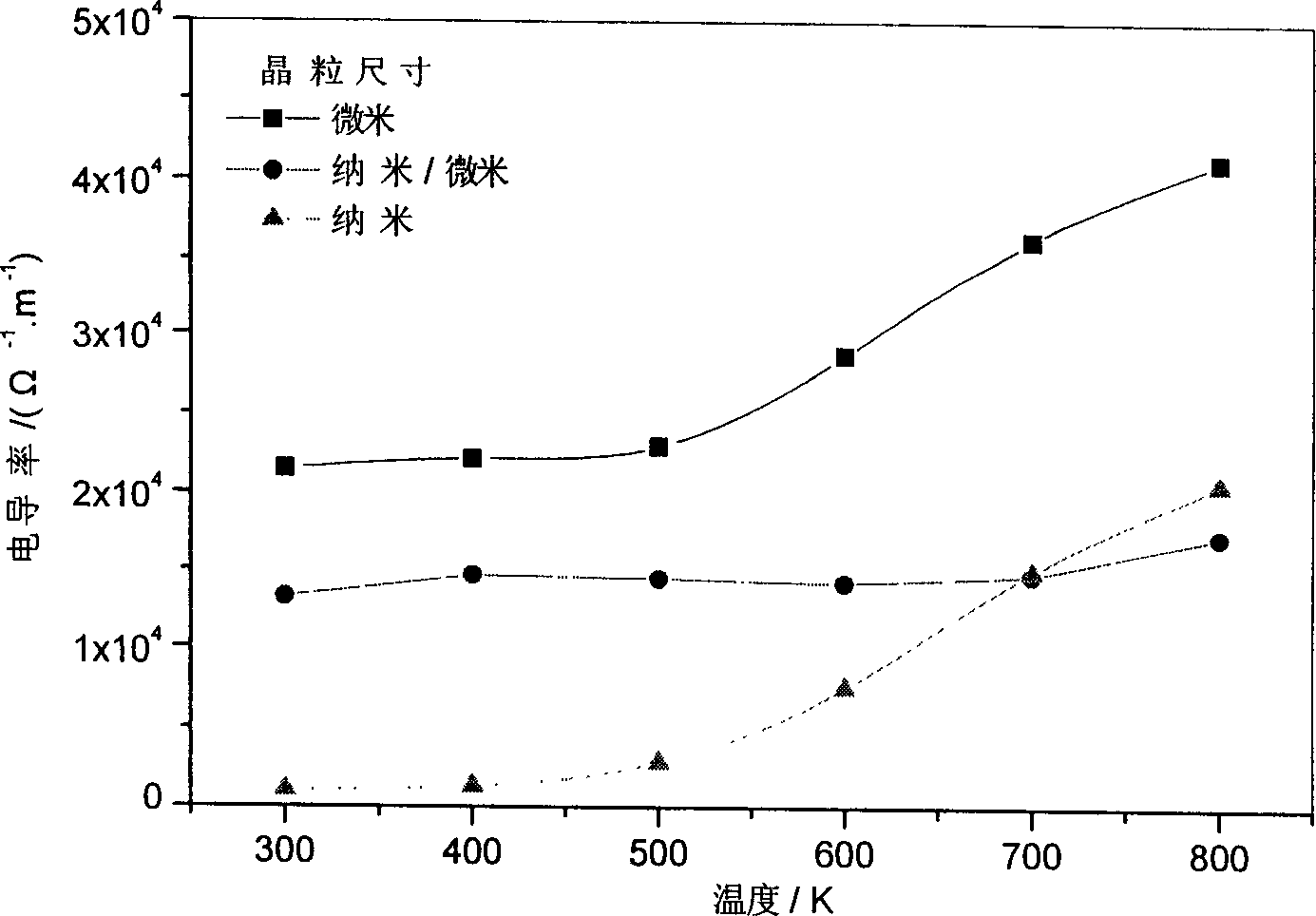

[0015] Example 3: Using metallic cobalt (90nm) and antimony (30μm) elemental powder as raw materials, press CoSb 3 The chemical formula of the compound weighs the ingredients, and the powder is ground and mixed under the protection of argon, and then put into a graphite mold for SPS in-situ reaction synthesis. The sintering conditions are: pressure 50MPa, heating rate 150°C / min, temperature 550°C, holding time 5min. Obtain CoSb with nano / micro composite grain structure 3 Dense bulk material, the relative density is 97.0%, the thermoelectric performance test results are as follows Figure 2-5 Shown. This material achieved a maximum ZT value of 0.34 at 700K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com