Fusion casting and welding method for aluminum parent metal

A welding method and base metal technology are applied in the field of casting and welding of aluminum base materials, which can solve the problems of less investment in practical applications and achieve the effect of large economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

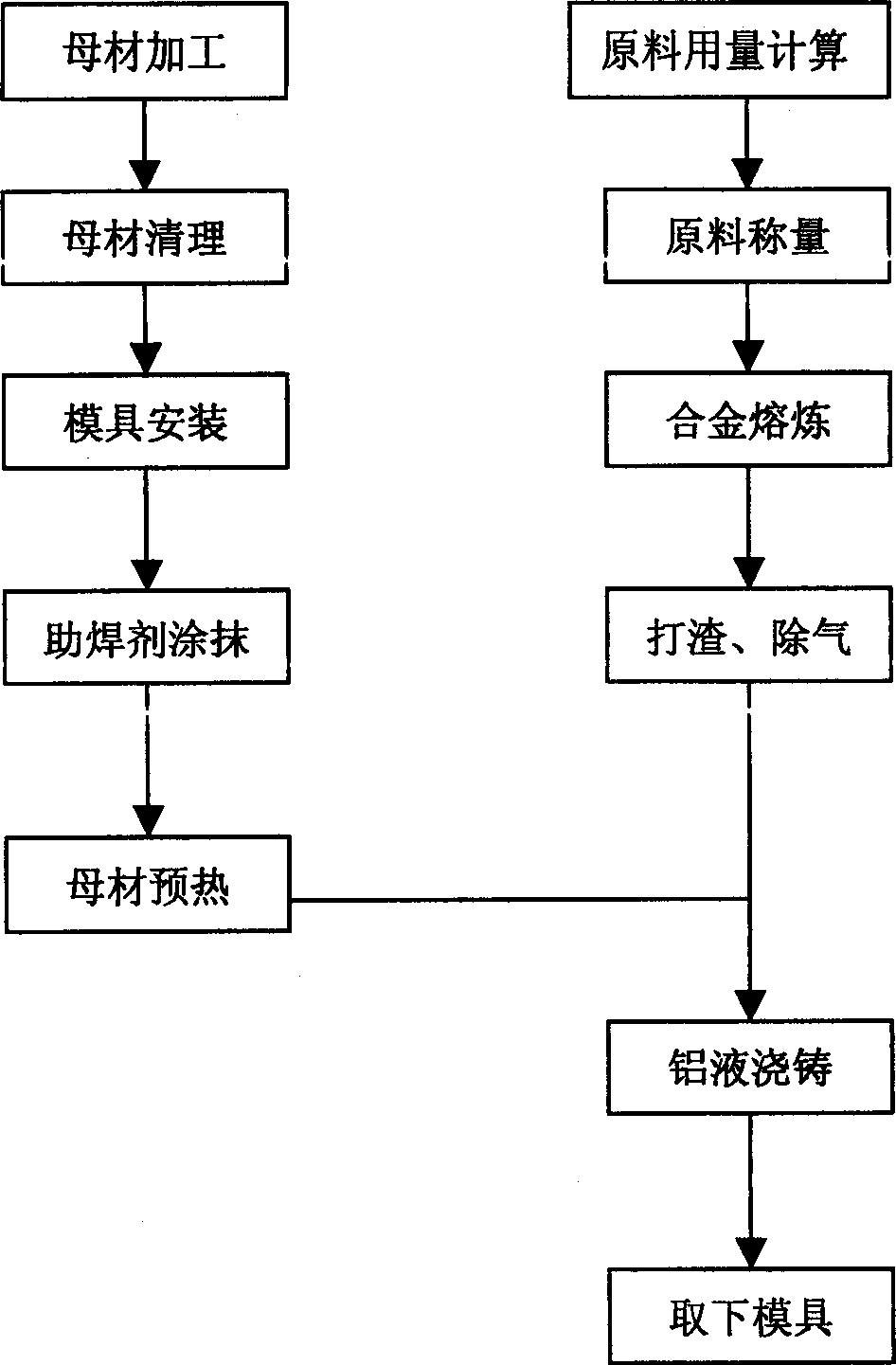

Method used

Image

Examples

Embodiment 1

[0022] Welding of aluminum bus bars in electrolytic plants:

[0023] 1. Process the parts to be welded of the aluminum base material neatly;

[0024] 2. According to the shape of the welding joint required by the base metal to be welded, a casting cavity is made at the joint position. The casting chamber is made of steel plates as fixtures. Put fire-resistant and flame-retardant materials such as asbestos boards into the fixture. The fire-resistant and flame-retardant material is a mixture of asbestos board, water glass and asbestos wool or asbestos rope.

[0025] After tightening the fixture, fill the gap between the steel plate and the aluminum base metal to be welded with a mixture of water glass and asbestos wool or asbestos rope, so as to make it sealed and prevent the aluminum liquid from leaking out. The shape of the casting chamber can be cuboid or truss.

[0026] The reason why fire-resistant and flame-retardant materials are added to the surface of the steel plat...

Embodiment 2

[0036] Match casting aluminum alloy, according to its proportioning: silicon 14%, copper 10%, aluminum 76%, all the other processes are with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com