Quick-drying alkide resin and preparation method thereof

An alkyd resin and fatty acid technology, applied in the field of quick-drying alkyd resin and preparation, can solve the problems of complex modification synthesis process, uneven molecular weight, poor pigment fusion, etc., and achieve high hardness, good gloss of paint film, dryness fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

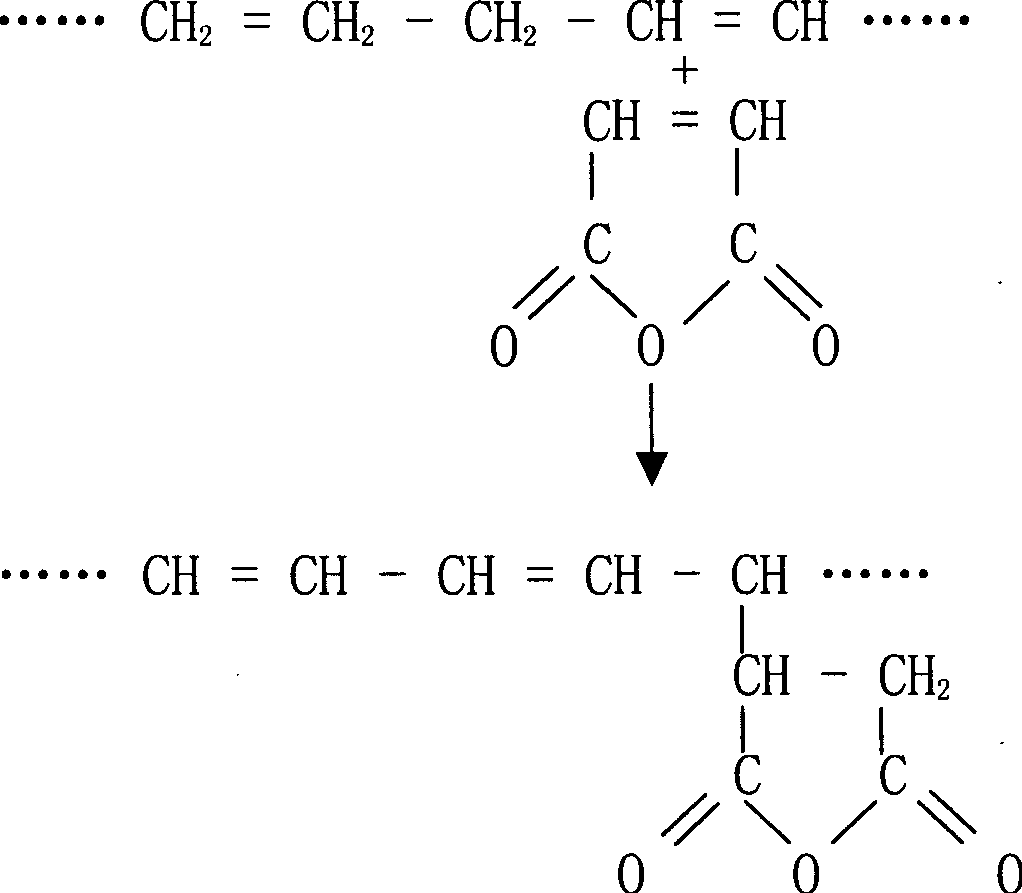

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Get 41% linolenic acid, 1% maleic anhydride, 16% phthalic anhydride, and 14% pentaerythritol, put them into a stainless steel reactor, seal the feeding port, open the vent valve, and pass CO 2 After 15 min of gas, stirring was started. Raise the temperature to 160°C, keep it warm for 30-60 minutes, then raise the temperature to 220°C and keep it warm for 6 hours, then take samples for the central control until the central control is qualified. Immediately pass nitrogen or CO after the central control is qualified 2 , cooled to 160°C adding part 200 # After mixing the solvent oil, start to add 28% VT dropwise. The temperature is controlled at 140±2°C. After 3 hours, take a sample for the central control, until the central control is qualified, take a sample to adjust the viscosity, and press filter and pack it when it is suitable. See the table below for specific technical parameters. The total reaction time was 22 hours.

Embodiment 2

[0028] Example 2: 36% soybean oil fatty acid, 0.8% maleic anhydride, 14.5% phthalic anhydride, and 13% pentaerythritol. The operation is the same as in Example 1. Addition and esterification reaction. After meeting the requirements, start to add 35.7% of VT dropwise. The operation is the same as in Example 1. 1, gained resin is lighter than embodiment 1 except color 3 # Other than that, the rest of the indicators are the same.

Embodiment 3

[0029] Example 3: 32% soybean oil fatty acid, 0.6% maleic anhydride, 12.4% phthalic anhydride, and 11% pentaerythritol. The operation is the same as in Example 1. Addition and esterification are reversed. After the requirements are met, 44% of VT is added dropwise. The operation is the same as the implementation Example 1, gained resin except that color is lighter than embodiment 1 3 # Other than that, the rest of the indicators are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com