Process for producing oligofructose of garlic

A technology of fructooligosaccharides and production methods, applied in the field of garlic fructooligosaccharides, can solve the problems of high production costs, achieve the effects of reducing product raw material costs, improving raw material utilization, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

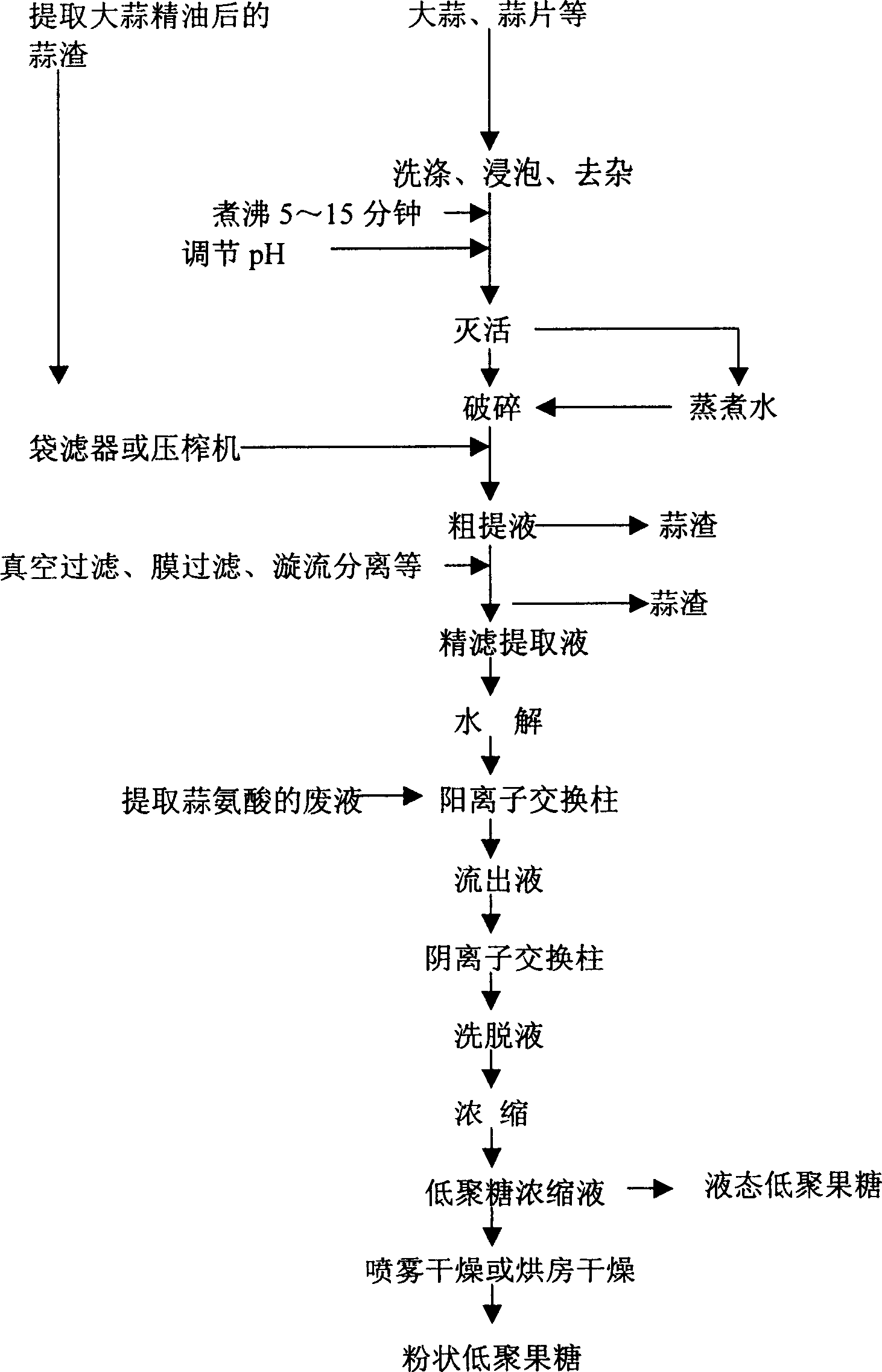

Image

Examples

Embodiment 1

[0030] With fresh garlic as raw material, such as figure 1 Shown technological process, specifically carry out according to the following steps:

[0031] The first step is pretreatment: put each kilogram of fresh garlic cloves in 2.5 liters of drinking water, soak for 4 hours, rinse with running water to remove impurities such as soil and garlic skin, control dry clear water, place on a steamer, and steam until round Steam for another 10 minutes, subject to steaming thoroughly and inactivating alliinase.

[0032] The second step is to prepare the garlic polysaccharide extract: add the steamed garlic cloves and cooking water to the beater to make garlic pulp of 100-150 mesh; filter the garlic pulp with a 250-mesh filter cloth (or bag filter) to obtain garlic Crude polysaccharide extract. The crude garlic extract is centrifuged at 4000 rpm for more than 20 minutes, and the supernatant obtained is filtered with a membrane with a molecular weight cut-off of 20,000 Daltons, and the...

Embodiment 2

[0038] With dehydrated garlic slices as raw material, proceed as follows:

[0039] The first step is to process the dehydrated garlic slices: soak the dehydrated garlic slices in 8 times drinking water for 1 to 2 hours, and boil for 10 minutes. Steam to soften and inactivate alliinase shall prevail.

[0040] The second step is to prepare the garlic polysaccharide extract: use the steamed garlic slices to make a 100-150-mesh garlic pulp with a beater, and filter it with a 250-mesh filter cloth to remove impurities such as garlic tissue particles and garlic skin to obtain a crude garlic extract. . The crude extract is centrifuged at 4000 rpm for more than 20 minutes, and the obtained supernatant is filtered through an inorganic membrane with a molecular weight cut-off of 20,000 to obtain a transparent garlic polysaccharide extract.

[0041] The third step is edible grade hydrochloric acid and citric acid to adjust the pH of the above-mentioned refined garlic polysaccharide ext...

Embodiment 3

[0048] Using fresh garlic as raw material, follow the steps below:

[0049] The first step is to prepare garlic polysaccharide extract: put 5000 grams of fresh garlic cloves and 12.5 liters of pH3 hydrochloric acid aqueous solution into a beater to make garlic pulp of 100-150 mesh, and process it through a bag filter and a press to remove Garlic tissue granules, garlic skin and other impurities are obtained to obtain garlic crude extract. A hydrocyclone is used to separate and remove suspended impurities, and the obtained supernatant is filtered with a plate and frame press (pressure 2 MPa) to obtain a transparent garlic polysaccharide extract.

[0050] The second step is to prepare the garlic polysaccharide extract: the steamed garlic slices are made into a 100-150-mesh garlic pulp with a beater, and filtered with a 250-mesh filter cloth to obtain a crude garlic extract. The crude extract is centrifuged at 3000 rpm for more than 20 minutes, and the obtained supernatant is fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com