Epitaxy base plate in use for solid-state semiconductor device, solid-state semiconductor device, and preparation method

A technology of epitaxial substrates and semiconductors, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor lasers, etc., can solve the problems of increasing equipment costs and time costs, and achieve the effects of reducing dislocation density, reducing time costs, and simplifying the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

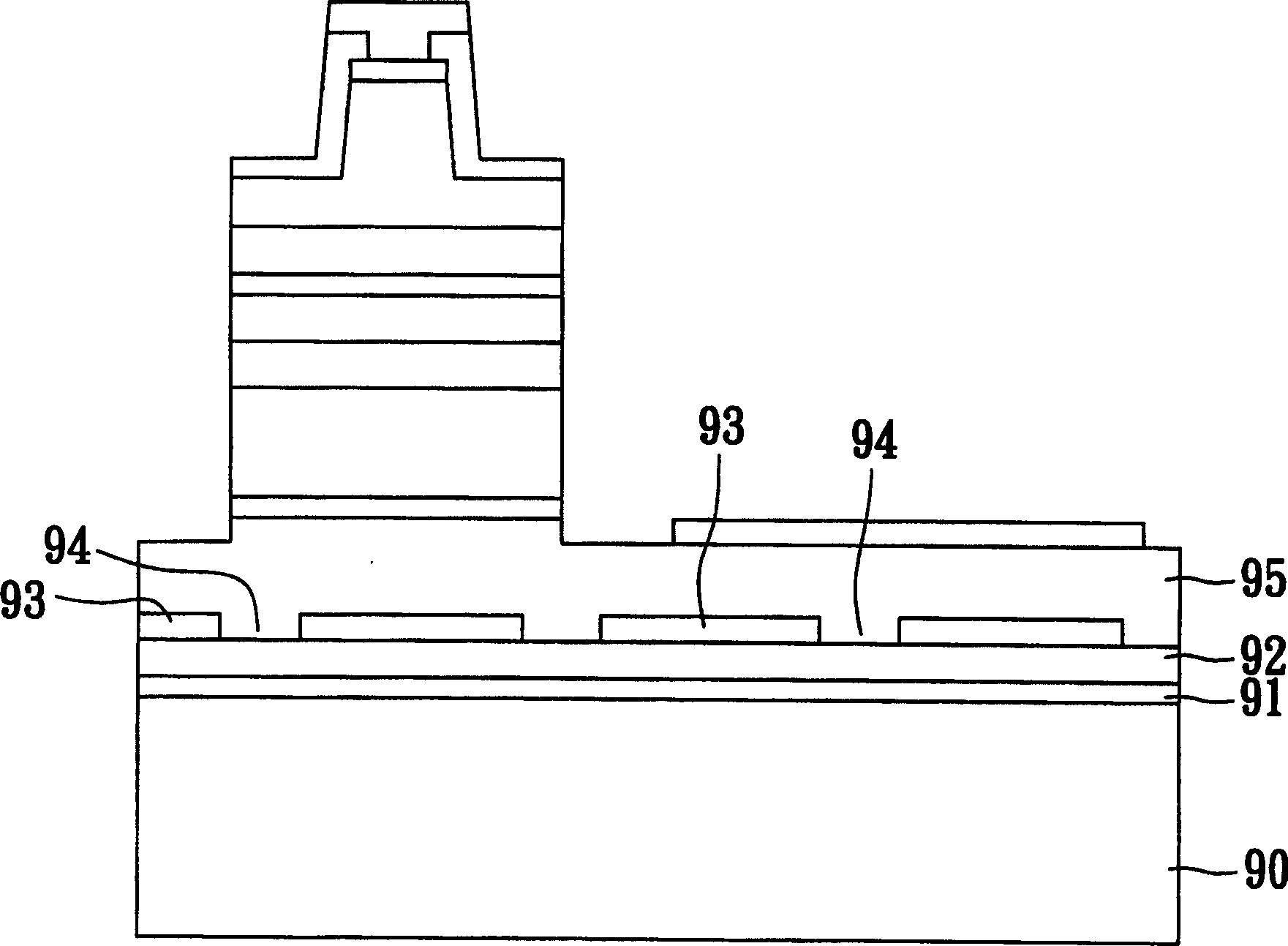

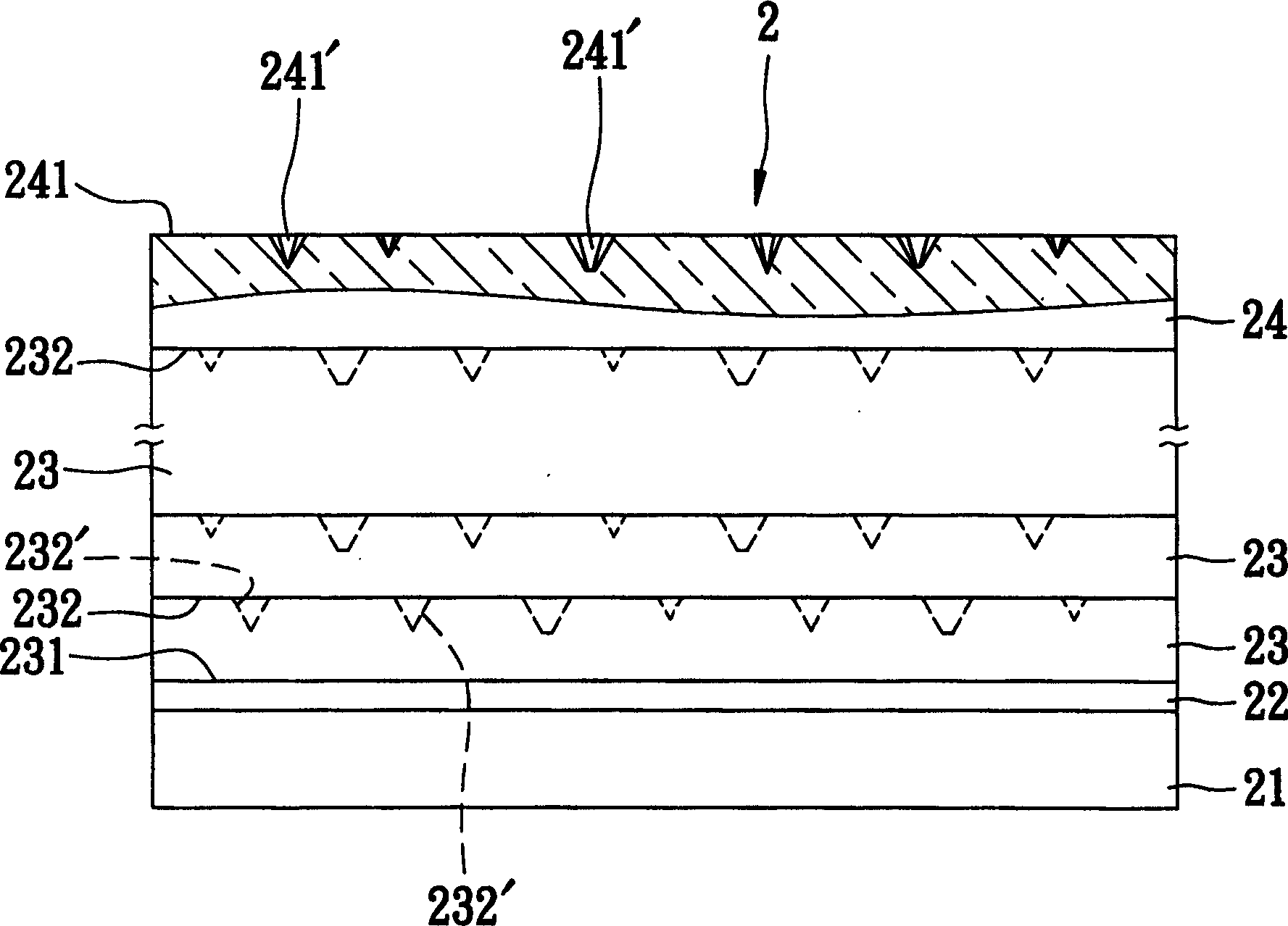

[0081] refer to image 3 and Figure 5 , In a specific embodiment of the present invention, the solid-state semiconductor device includes: an epitaxial substrate 2 and an emitting unit 3 formed on the epitaxial substrate 2 .

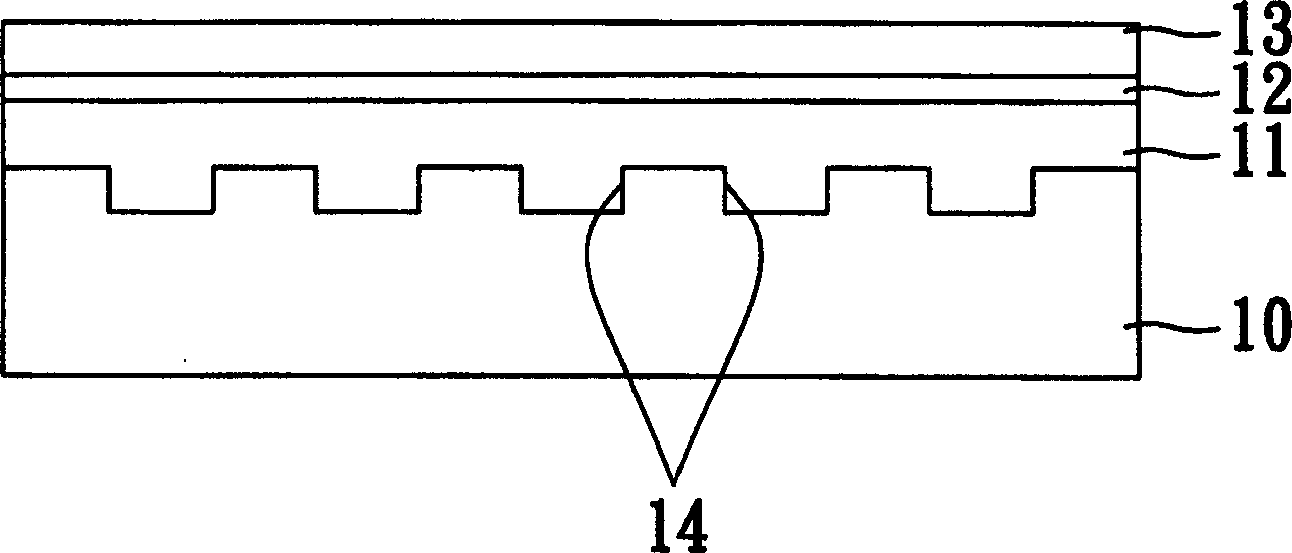

[0082] The epitaxial substrate 2 has a board body 21, a buffer film 22 connected to the board body 21, a second second groove 241' formed on the buffer layer 22 and having a plurality of hexagonal grooves 241' with irregular sizes. The epitaxial film 24 , and a plurality of first epitaxial films 23 sandwiched between the second epitaxial film 24 and the buffer film 22 and having a plurality of hexagonal grooves 232 ′ with irregular sizes. In this embodiment, the board body 21 is made of sapphire with a hexagonal crystal structure, and the epitaxial films 23 and 24 are made of gallium nitride (GaN).

[0083] In the emitting unit 3 of this embodiment, the first type semiconductor layer 311 is made of n-GaN, and the light emitting layer 312 is a multilayer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com