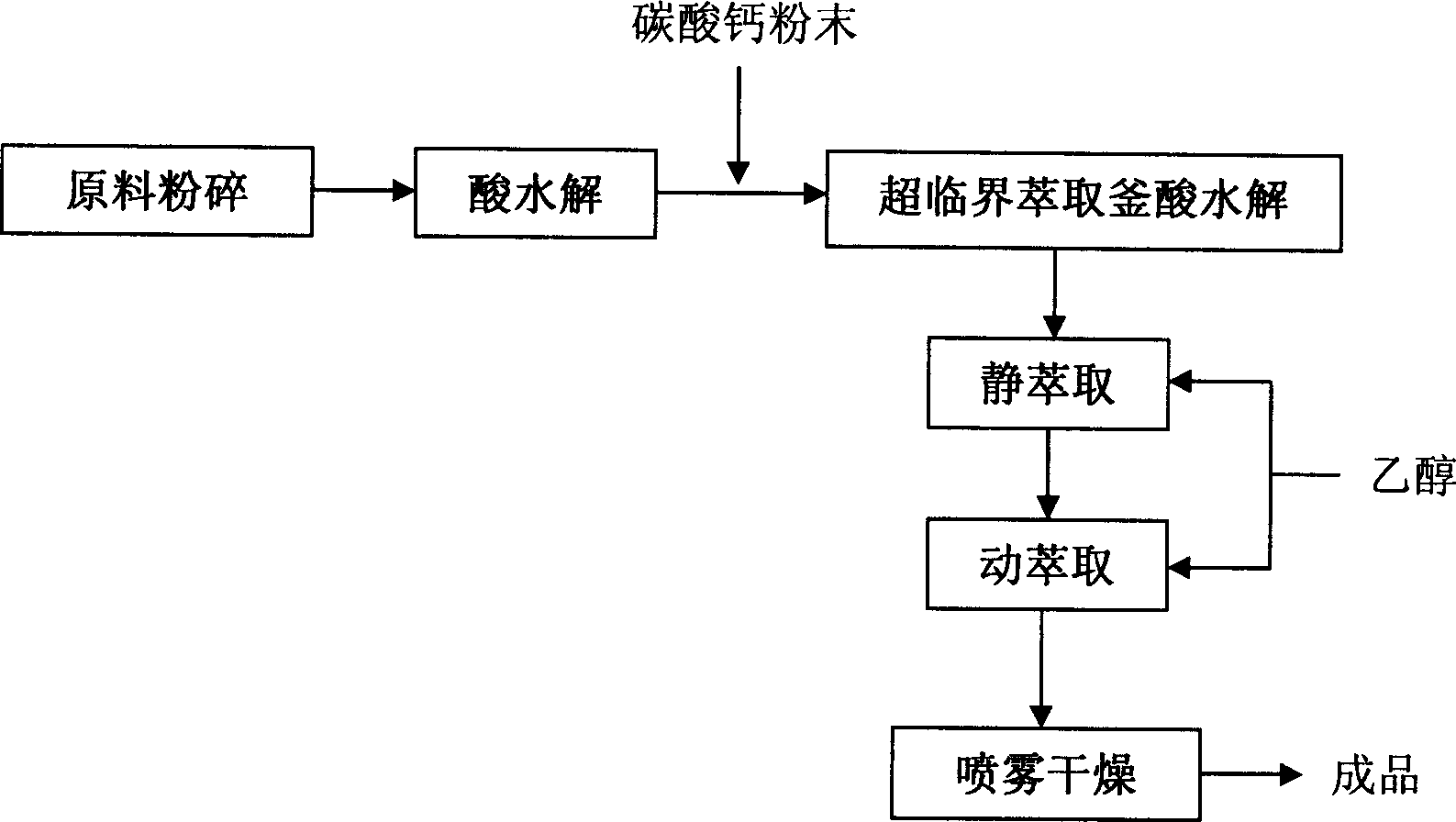

Method for extracting rhubarb powder dissociated anthraquinone by supercritical acid hydrolysis

A free anthraquinone, supercritical technology, applied in quinone separation/purification, bulk chemical production, organic chemistry and other directions, can solve the problems of high production cost, cumbersome operation, large consumption of organic solvents, etc. Simple process and low solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

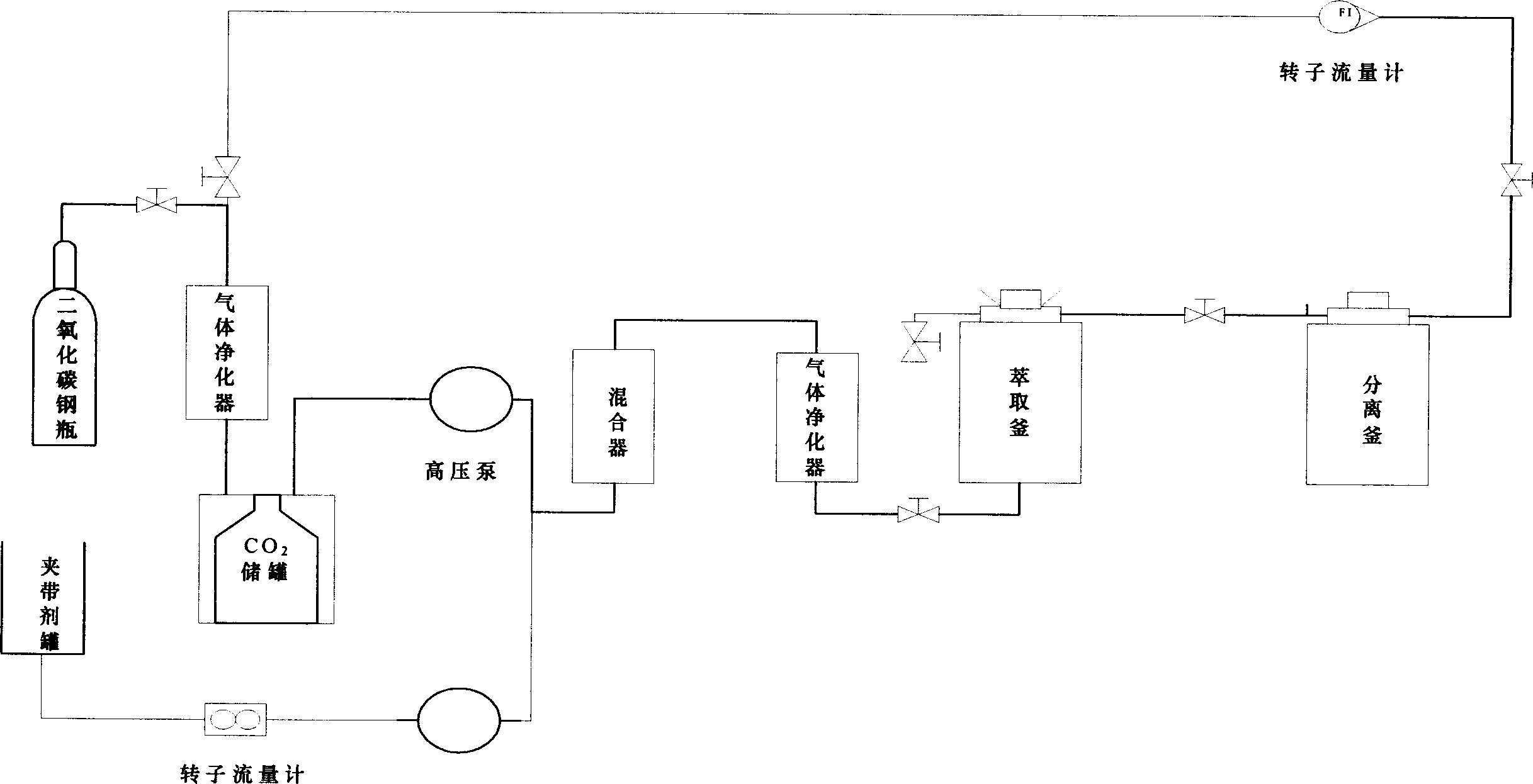

Embodiment 1

[0029] Take 100 grams of 80 mesh rhubarb crude drug powder, add 150ml of 5mol / l concentrated hydrochloric acid and hydrolyze it at 60° for 1.5 hours. After the reaction is complete, add 25 grams of calcium carbonate and mix to neutralize the excess hydrochloric acid until no bubbles are generated. Put the rhubarb powder into a supercritical extraction kettle, add 100ml of 99% ethanol at the same time, and extract statically for 0.5 hours, the extraction pressure is 45MPa, and the extraction temperature is 60°C. After that, add 200ml of 99% concentrated ethanol from the entrainer pump at a rate of 6ml / min, and perform dynamic extraction for 1 hour, keeping the same extraction pressure and temperature as static extraction, the separation tank pressure is 4MPa, and the average flow rate of carbon dioxide is 0.5l / min. Collect the product from the separation tank and spray dry under reduced pressure to obtain 2.65 grams of rhubarb free anthraquinone powder. Its purity is 98.8% as...

Embodiment 2

[0034] Take 300 grams of 80 mesh rhubarb crude drug powder, add 300ml of 5mol / l concentrated hydrochloric acid and hydrolyze it at 60° for 1.5 hours, after the reaction is complete, add 75 grams of calcium carbonate and mix to neutralize the excess hydrochloric acid until no bubbles are generated. Put the rhubarb powder in a 21-degree supercritical kettle, add 300ml of 99% ethanol at the same time, and extract it statically for 0.5 hour, the extraction pressure is 45MPa, and the extraction temperature is 60°C. Afterwards, add 99% concentrated ethanol 600ml from the entrainer pump at a rate of 19ml / min, and extract dynamically for 1.1 hours, keep the same extraction pressure and temperature as the static extraction, the separation tank pressure is 4MPa, and the average flow rate of carbon dioxide is 0.5l / min. Collect the product from the separation tank and spray dry it under reduced pressure to obtain 8.05 grams of rhubarb free anthraquinone powder. Its purity is greater tha...

Embodiment 3

[0036] Take 800 grams of 80 mesh rhubarb crude drug powder, add 800ml of 5mol / l concentrated hydrochloric acid and hydrolyze it at 60° for 1.5 hours, after the reaction is complete, add 200 grams of calcium carbonate and mix to neutralize the excess hydrochloric acid until no bubbles are produced. Put the rhubarb powder in a 21-degree supercritical kettle, add 800ml of 99% ethanol at the same time, and extract it statically for 0.5 hour, the extraction pressure is 45MPa, and the extraction temperature is 60°C. Afterwards, add 99% concentrated ethanol 1600ml from the entrainer pump at a rate of 50ml / min, and extract dynamically for 1.1 hours, keep the same extraction pressure and temperature as the static extraction, the separation tank pressure is 4MPa, and the average flow rate of carbon dioxide is 0.5l / min. Collect the product from the separation tank and spray dry it under reduced pressure to obtain 22.05 grams of rhubarb free anthraquinone powder. Its purity is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com