Method for preparing three-dimensional nanometer structure titanium dioxide

A titanium dioxide, three-dimensional nanotechnology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to achieve the effect of simple method, large specific surface area and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1 Prepare pickling solution

[0022] Mix hydrofluoric acid with a concentration of 55% by mass, nitric acid with a concentration of 65% by mass, and deionized water in a volume ratio of 1:3:6 to obtain a pickling solution.

[0023] Step 2 Surface cleaning of metal titanium plate

[0024] The size is 5×5×0.01(cm 3 ) The surface of the metal titanium plate is pickled with the above-mentioned mixed acid at a temperature of 60° C., and then cleaned with deionized water in ultrasonic waves.

[0025] Step 3 Prepare the reaction solution

[0026] Add 1.0 ml of nitric acid with a concentration of 63% (mass percentage) and 100 mg of hexamethylene tetraazol (purity>99.5% by mass) to 50 ml of 30% (mass percent) hydrogen peroxide solution in sequence to obtain a reaction solution.

[0027] Step 4 Reaction

[0028] Submerge the cleaned metal titanium plate in 50ml of reaction solution, and react at 80°C for 72 hours.

[0029] Step 5 heat treatment

[0030] The reacted tit...

Embodiment 2

[0034] Step 1 Prepare pickling solution

[0035] With embodiment 1.

[0036] Step 2 Surface cleaning of metal titanium plate

[0037] With embodiment 1.

[0038] Step 3 Prepare the reaction solution

[0039] Add 4.0 ml of nitric acid with a concentration of 63% (mass percentage) and 100 mg of hexamethylene tetraazol (purity > 99.5% by mass) to 50 ml of a 30% (mass percent) hydrogen peroxide solution to obtain a reaction solution.

[0040] Step 4 Reaction

[0041] Submerge the cleaned metal titanium plate in 50ml of reaction solution, and react at 60°C for 60 hours.

[0042] Step 5 heat treatment

[0043] The reacted titanium sheet was gently rinsed with deionized water, dried and placed in a muffle furnace at 500° C. for 0.5 hours.

[0044] Response result

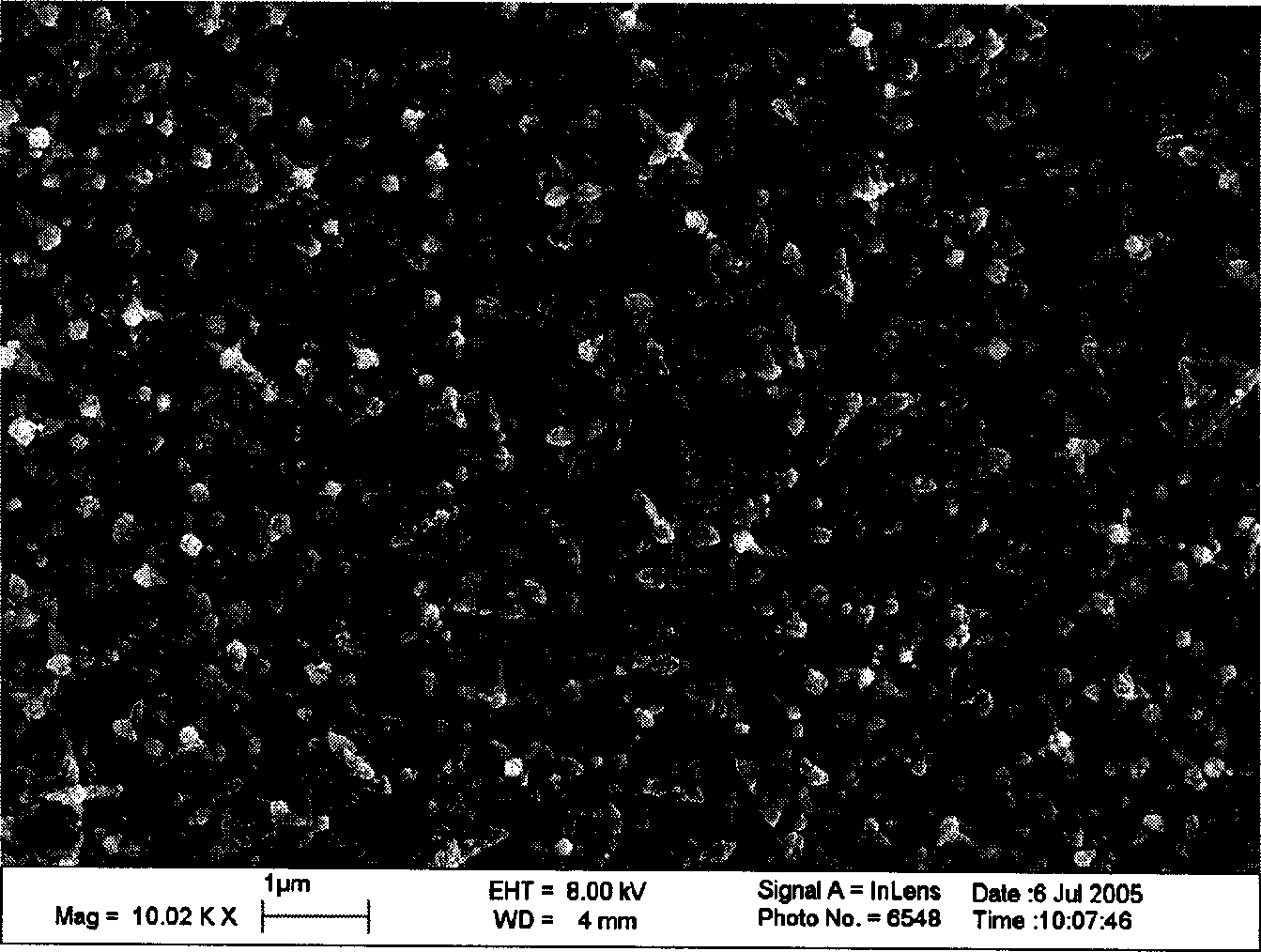

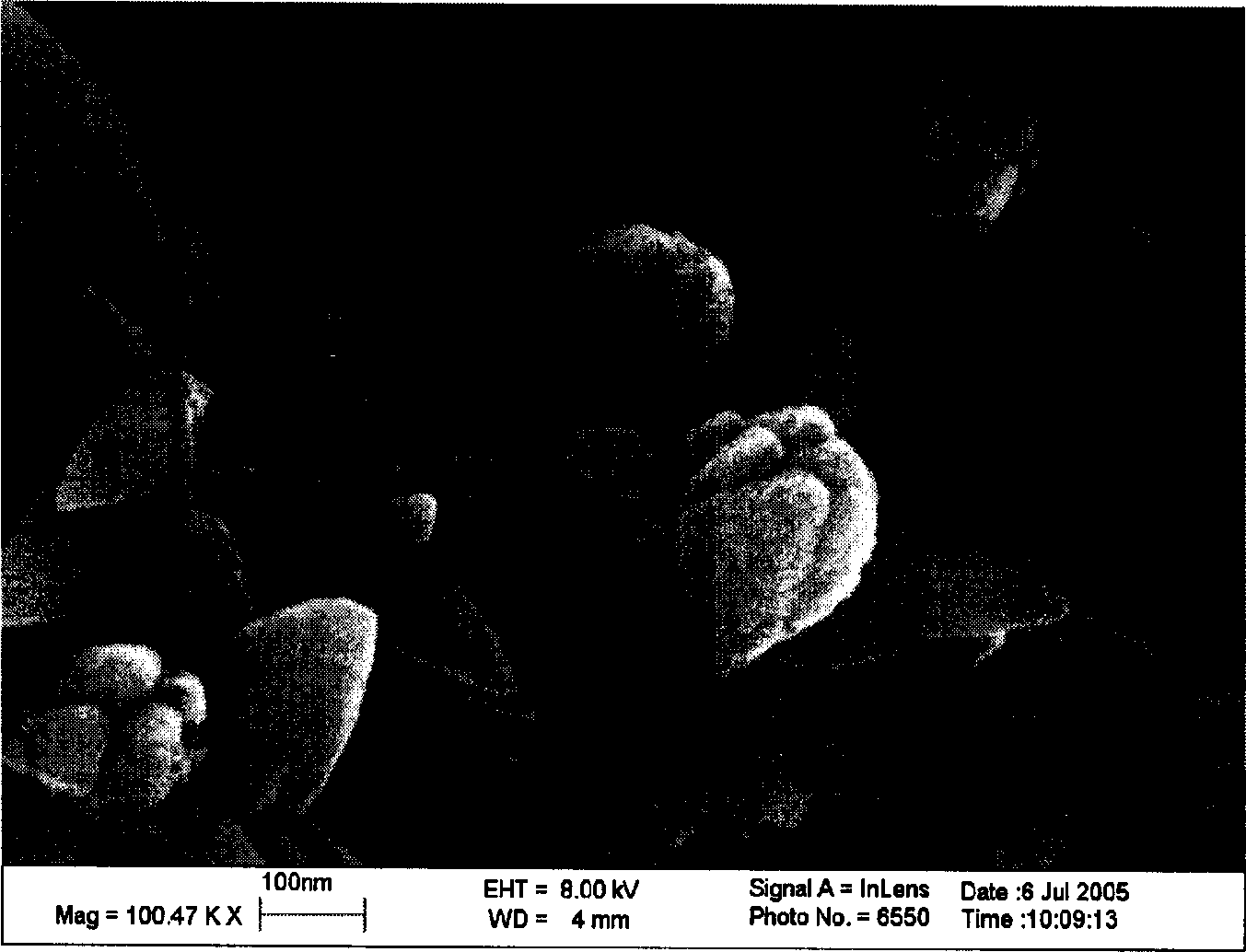

[0045] The surface of the titanium plate is uniformly generated as Figure 5 The shown "nanoflower" structure titanium dioxide, "nanoflower" diameter of about 500 nanometers. Titanium dioxide with "nanoflower" str...

Embodiment 3

[0047] Step 1 Prepare pickling solution

[0048] Mix hydrofluoric acid with a concentration of 50% by mass, nitric acid with a concentration of 68% by mass, and deionized water in a volume ratio of 1:4:7 to obtain a pickling solution.

[0049] Step 2 Surface cleaning of metal titanium plate

[0050] With embodiment 1.

[0051] Step 3 Prepare the reaction solution

[0052] Add 2.0 ml of nitric acid with a concentration of 63% (mass percentage) and 100 mg of hexamethylene tetraazol (purity > 99.5% by mass) to 50 ml of 30% (mass percent) hydrogen peroxide solution in sequence to obtain a reaction solution.

[0053] Step 4 Reaction

[0054] With embodiment 1.

[0055] Step 5 heat treatment

[0056] With embodiment 1.

[0057] Response result

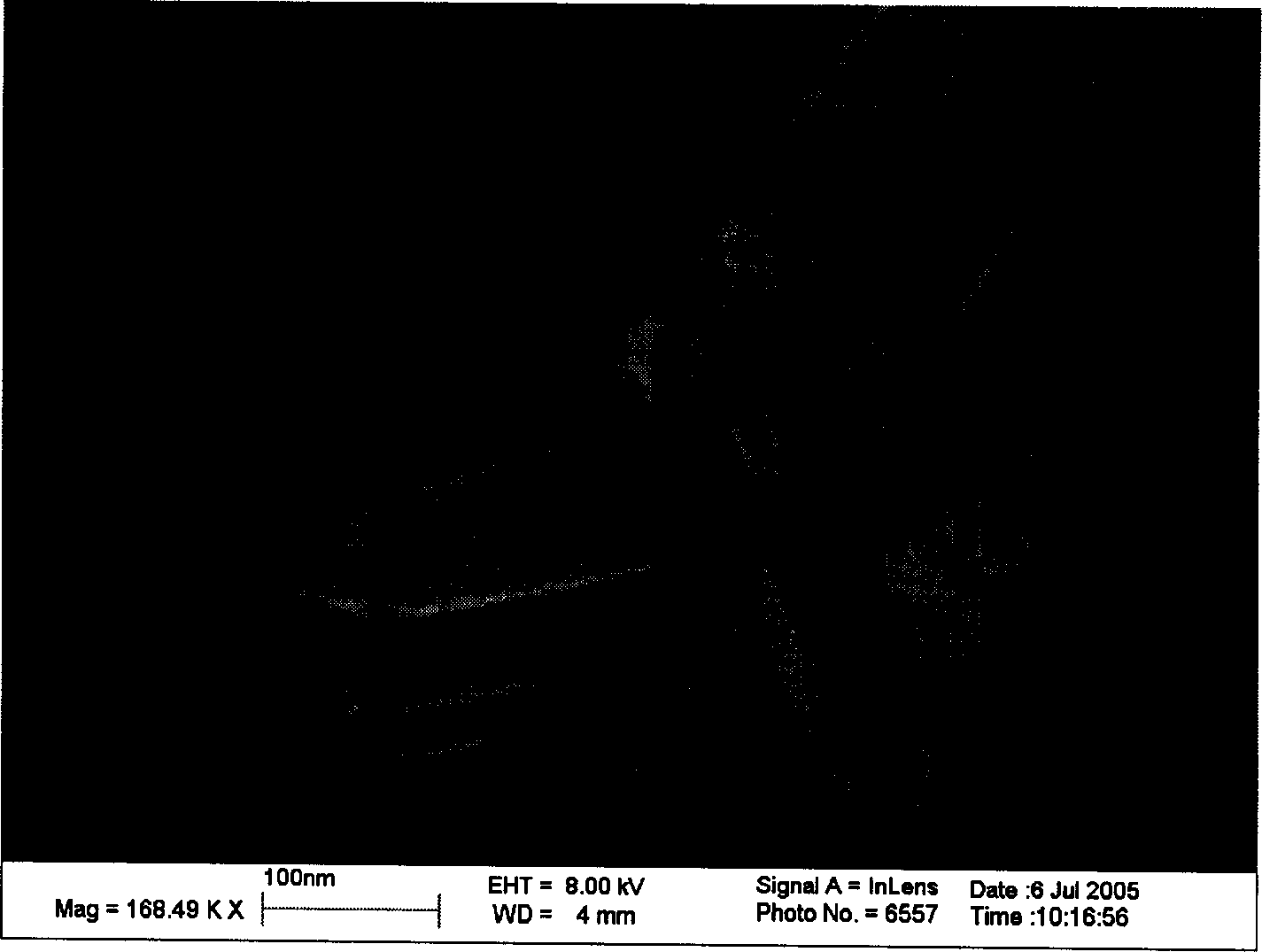

[0058] The surface of the titanium plate is uniformly generated as Figure 7 The shown "nanoflower" structure titanium dioxide, "nanoflower" diameter of about 500 nanometers. Before the heat treatment, the "nano flower" structure ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com