Method for deep treatment of bromine ion-containing drinking water

A technology for advanced treatment and drinking water, applied in the field of water treatment, can solve the problems of ineffective removal of disinfection by-products and excessive bromic acid by-products, and achieve the effects of enhancing coagulation-assisting effect, low cost, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

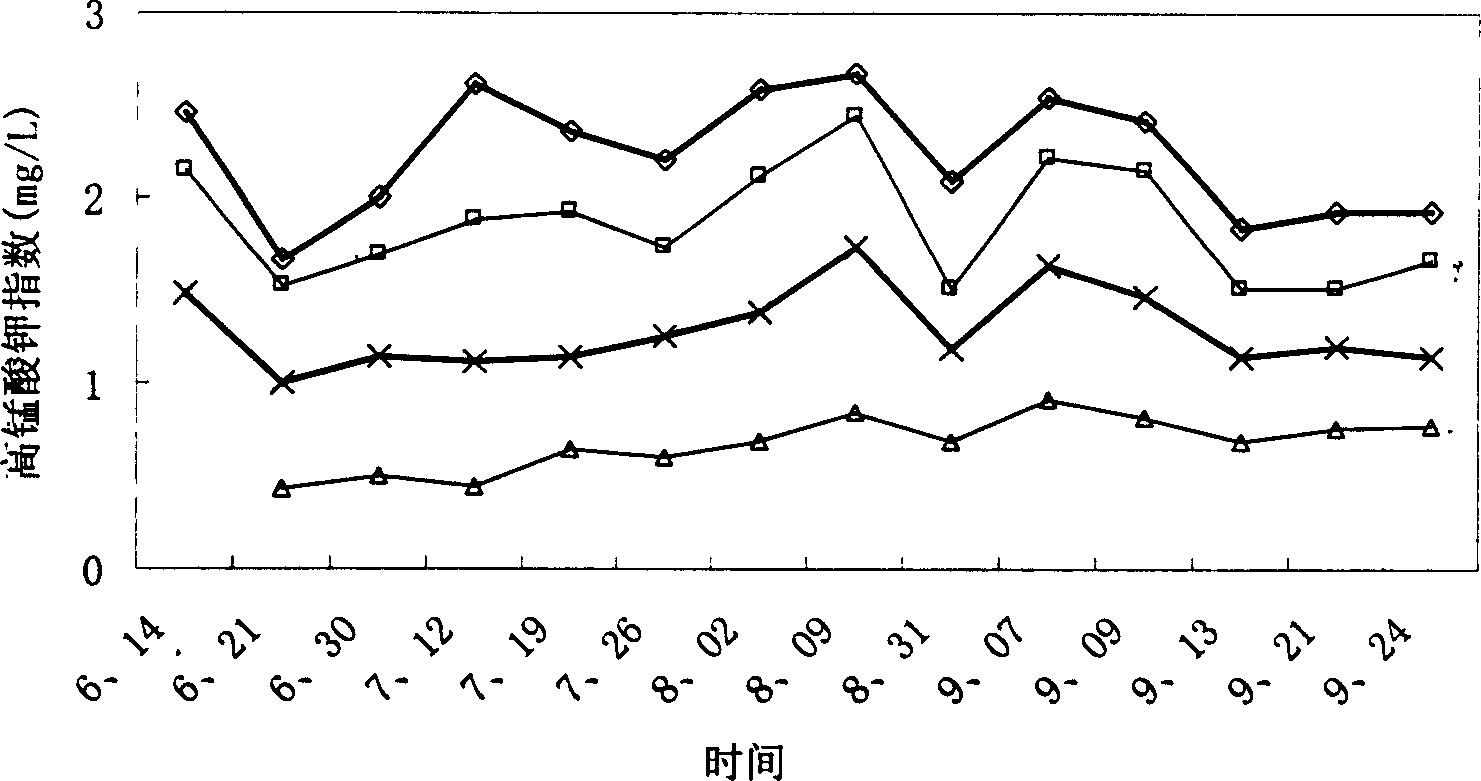

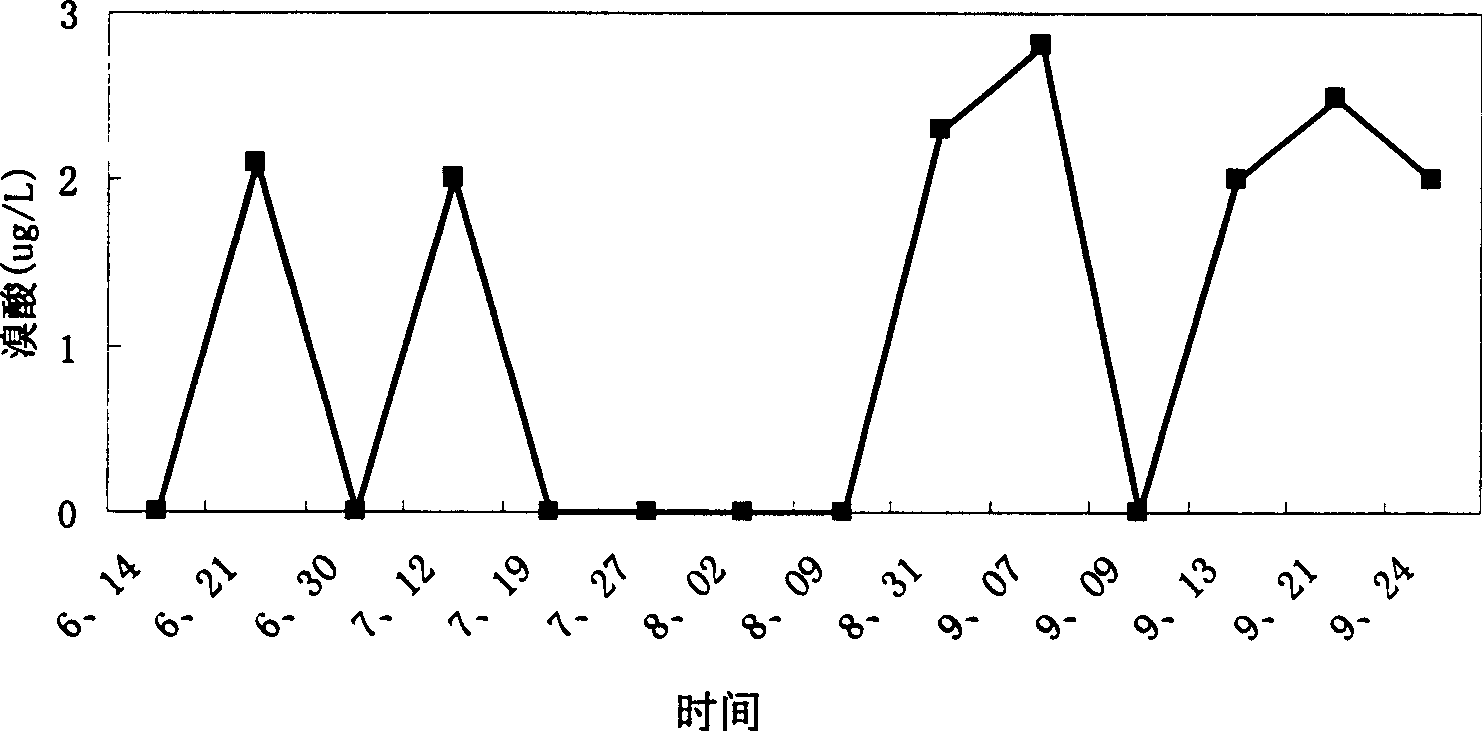

[0020] This embodiment adopts the raw water of a reservoir in Shenzhen City, Guangdong Province in the south of my country. The raw water is listed in Table 1 and has the characteristics of high algae, low turbidity, slight pollution, and bromide ion content.

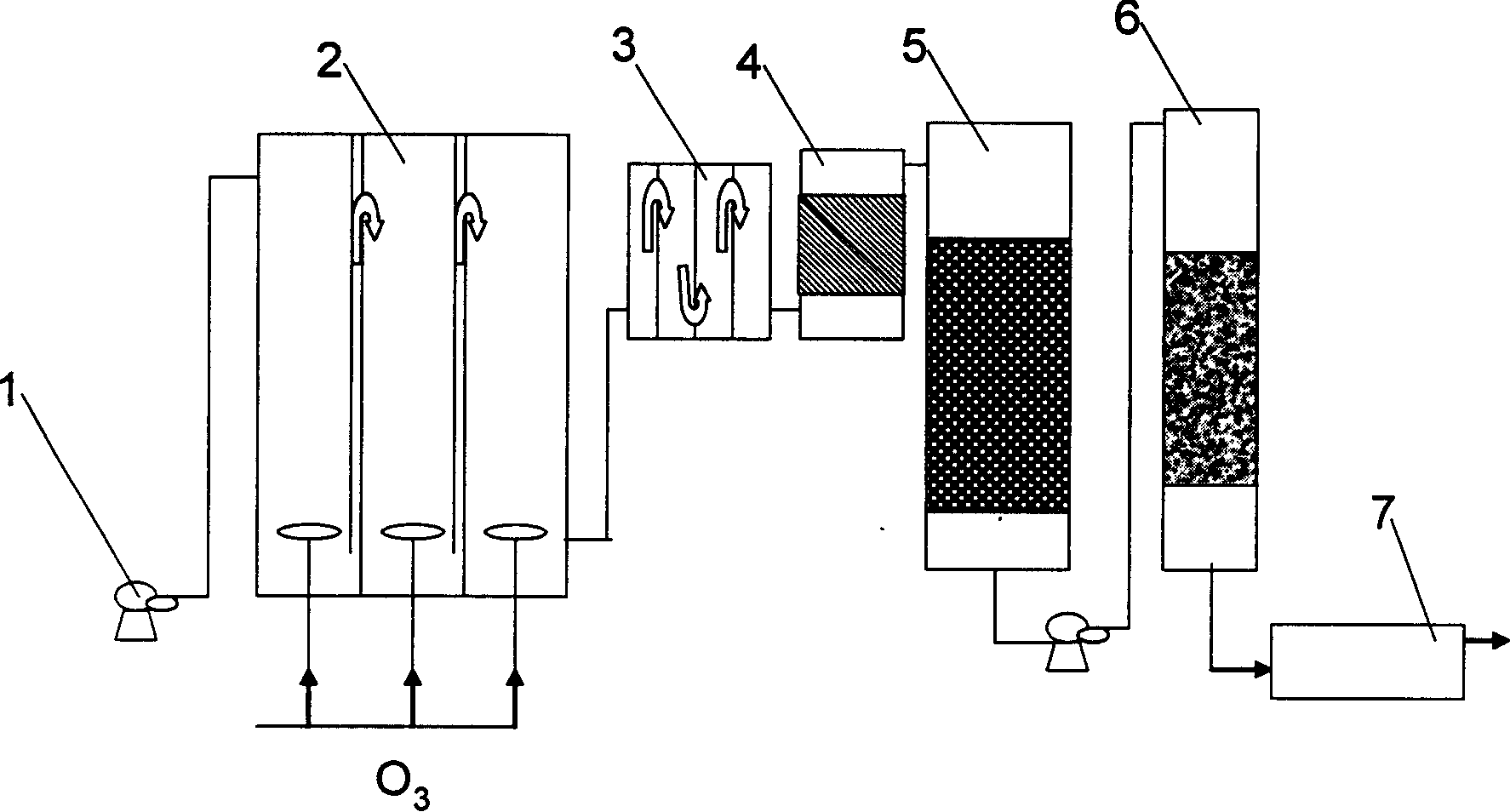

[0021] Devices for advanced water treatment such as figure 1 As shown, 1 lifting pump, 2 ozone contact tank, 3 coagulation reaction tank, 4 sedimentation tank, 5 sand filter tank, 6 biological activated carbon filter tank, 7 disinfection water tank. First, the raw water is injected into the ozone oxidation reaction device 2 through the lift pump 1 for ozone oxidation. The ozone reaction amount is 0.5 mg / L raw water. After a contact time of 4 minutes, it enters the coagulation device 3-precipitation device 4 for flocculation reaction and precipitation. The flocculant is polyaluminum chloride (PAC), and after a residence time of 45 minutes, it enters the sand filter device 5; then, it passes through the biological activat...

Embodiment 2

[0026] The raw water hardness / TOC of a reservoir is 16 (less than 25), therefore, the pre-liming process is adopted. First, lime is added to the raw water for mixing (dosing amount is 15mg / L), and the raw water is injected into the ozone oxidation reaction device 2 through the lift pump 1 for ozone oxidation. The amount of ozone reaction is 2.0mg / L of raw water. Coagulation device 3-precipitation device 4, carries out flocculation reaction and precipitation, and the flocculant used is polyaluminum chloride (PAC), and after residence time 45 minutes, enters sand filtration device 5; It takes 15 minutes (biological activated carbon is formed by the method of biological natural film formation); finally, it enters the disinfection pool and is chlorinated for disinfection.

[0027] The raw water quality and the effluent water quality after lime treatment are listed in Table 2.

[0028] project

Embodiment 3

[0030] In this embodiment, the raw water contains Zhongbucarb pesticide residues, therefore, hydrogen peroxide is added, and the weight ratio of the amount of hydrogen peroxide to the amount of ozone added is 0.20 (wherein the amount of ozone added is 1.57 mg / L).

[0031] First, the raw water is injected into the ozone oxidation reaction device 2 through the lift pump 1 for ozone oxidation. The ozone reaction amount is 1.57mg / L raw water. After a contact time of 4 minutes, hydrogen peroxide (weight ratio is 0.20) is added at the outlet of the ozone contact tank. Enter the coagulation device 3-precipitation device 4, carry out flocculation reaction and precipitation, the flocculant used is polyaluminum chloride (PAC), after the residence time of 45 minutes, enter the sand filter device 5; Then, pass through the biological activated carbon pool 6, hydraulic The residence time is 15 minutes (biological activated carbon is formed by the method of biological natural film formation);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com