Electric variable speed drive apparatus with brake energy recovery function for vehicles

A technology of variable speed transmission and brake recovery, applied in electromechanical transmission devices, battery circuit devices, electromechanical devices, etc., can solve the problems of increasing the difficulty and labor intensity of the driver's operation, low comprehensive transmission efficiency, and high fuel consumption. The effect of reducing continuous working time, reducing fuel consumption and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific structure, working process and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

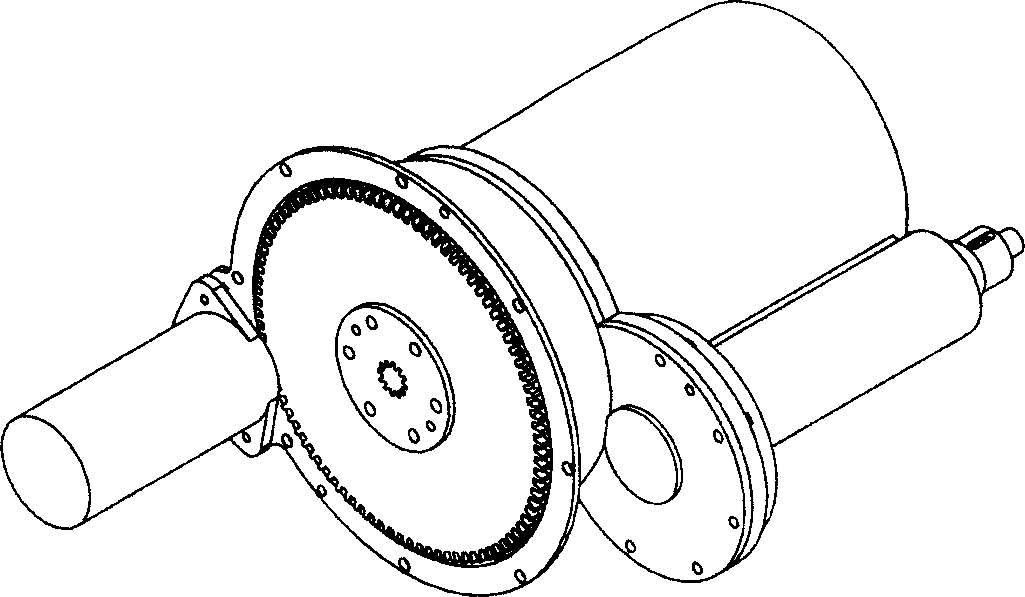

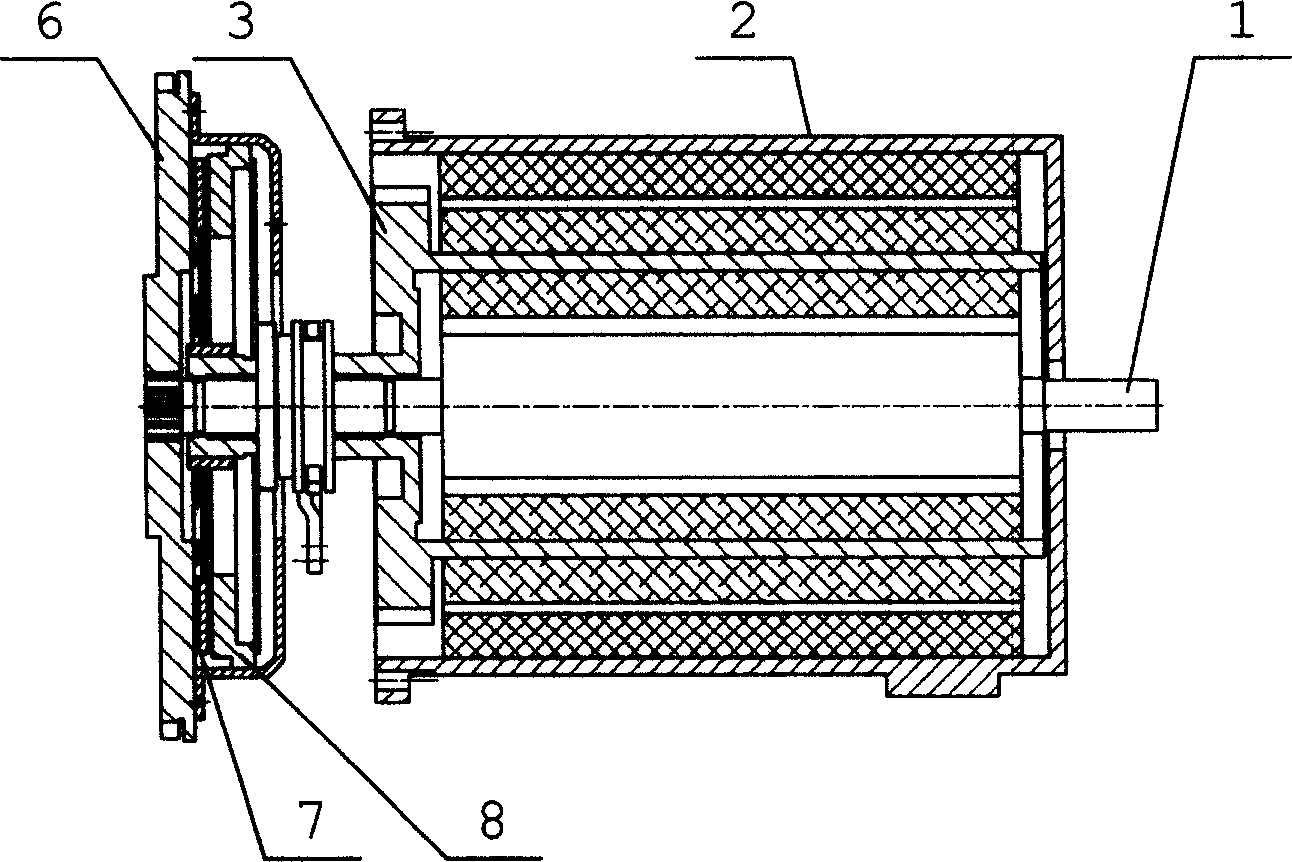

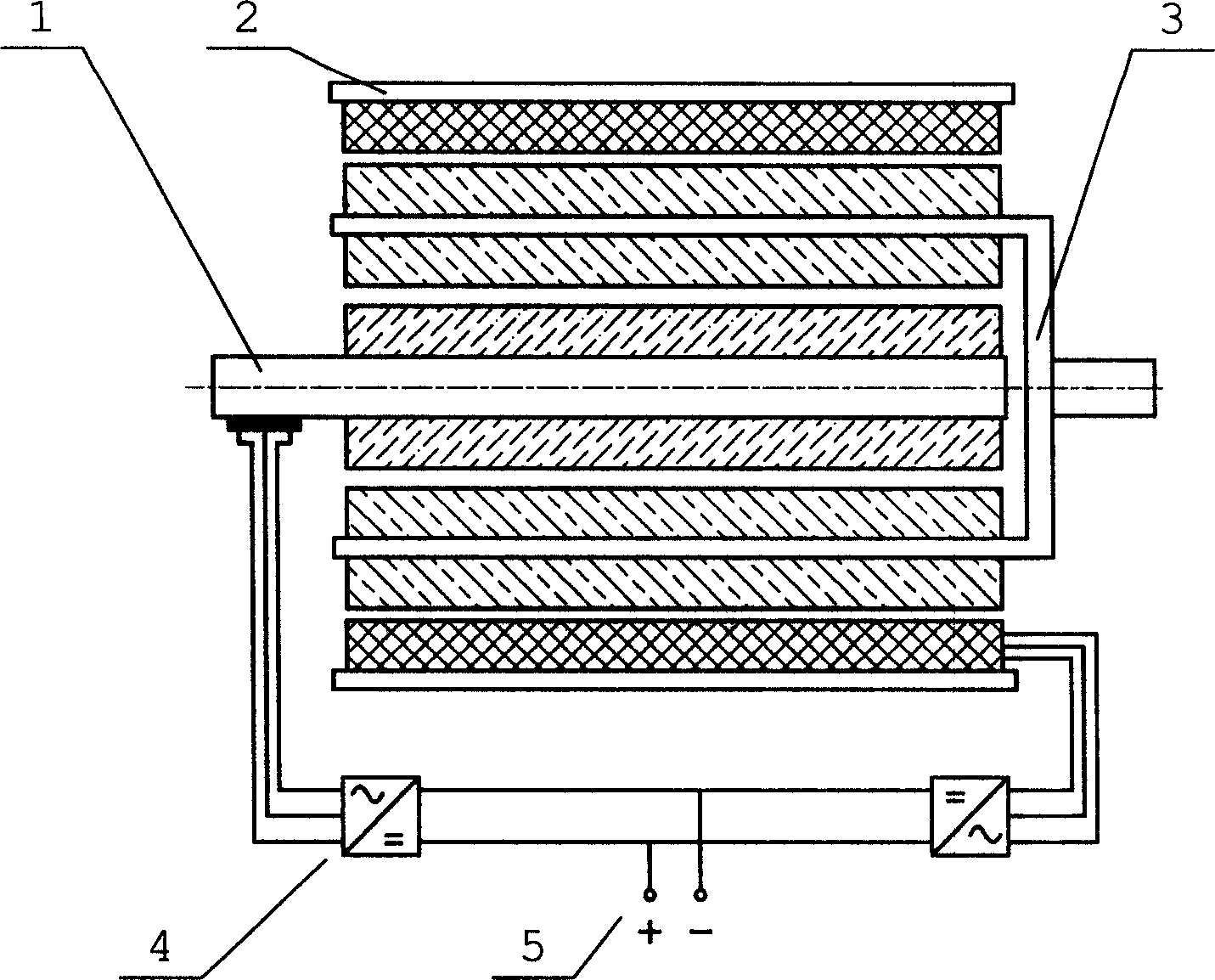

[0020] The electric variable speed transmission device provided by the present invention with brake recovery electric energy for vehicles mainly includes clutch, engine flywheel 6, dual-rotor electric transmission and electrohydraulic brake 11; the clutch is composed of clutch driven disc assembly 7 , a clutch cover assembly 8, a separation fork bearing set 9; the dual-rotor electric transmission consists of an inner rotor 1, an intermediate rotor 3, an outer stator 2, and two back-to-back motors for controlling the current frequency of the inner rotor and the outer stator Composed of frequency conversion converter 4, one end of the inner rotor 1 is connected with the engine flywheel 6, one end of the intermediate rotor 3 is connected with the driven disc assembly 7 of the clutch through a sliding key, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com