Microporous bone cement and bone paste

A technology of bone cement and microporous bone, used in bone implants, medical science, prostheses, etc., can solve the problems of loose prosthesis, inability to repair bone defects, normal bone necrosis, etc., to reduce the normal bone body. Necrosis, reducing loosening and rework, ensuring a strong bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] [Example 1] Preparation of Microporous Bone Cement

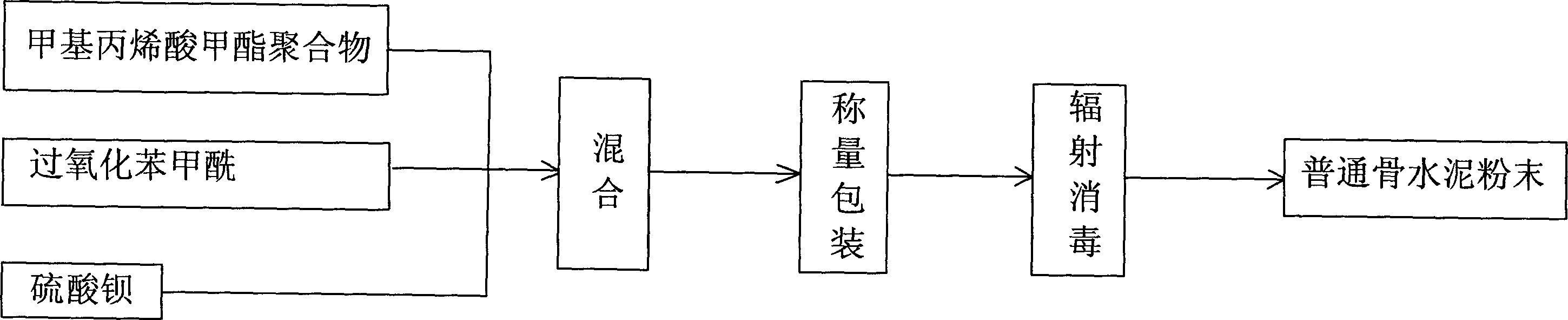

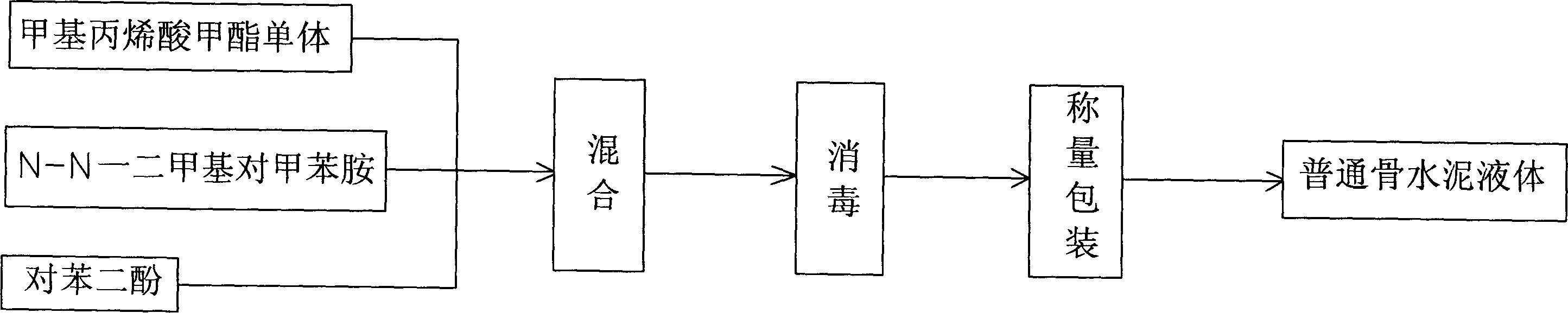

[0044] After mixing 88g of polymethylmethacrylate, 2g of benzoyl peroxide and 10g of barium sulfate, sterilize to make 100g of ordinary bone cement powder; take 49ml of methylmethacrylate, N, N-dimethylterephthalene After mixing amine 1ml, add 5×10 -4 g Hydroquinone is made into common bone cement liquid, wherein the concentration of hydroquinone in the bone cement solution is one hundred thousandth of a gram per liter. Take 40 g of ordinary bone cement powder and 20 ml of ordinary bone cement liquid, and pack them separately after sterilization to obtain ordinary bone cement.

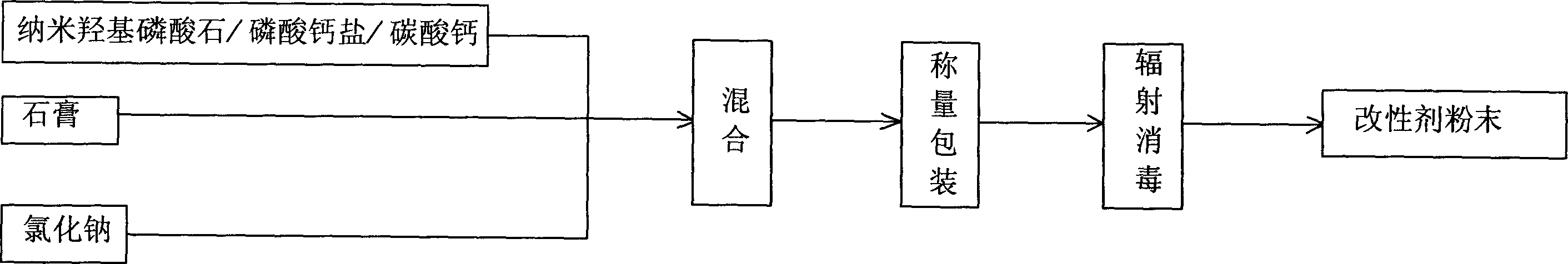

[0045] After mixing gypsum 2g, calcium phosphate 2g and sodium chloride 1g, carry out disinfection to make modifier powder; mix modifier powder with 4ml distilled water to make slurry modifier for later use;

[0046] Take 22.5g of ordinary bone cement in slurry form and mix it with the modifier in slurry form and mix it at high speed for abo...

Embodiment 2

[0049] [embodiment 2] preparation of bone paste

[0050] After mixing gypsum 4g, nano-hydroxyapatite 4g and sodium chloride 1g, modifying agent powder is made; modifying agent powder is mixed with 8ml water, and the modifying agent made into slurry is standby; according to embodiment 1 The method for preparing ordinary bone cement; take 15g of ordinary bone cement in the form of slurry and the above-mentioned modifier in the form of slurry for high-speed mixing for about 1-1.5 minutes, and the bone paste product can be obtained after mixing and stirring evenly.

[0051] Put the above-mentioned bone paste into a syringe, inject it into a plastic tube of ∮8×17mm, and harden after 15-18 minutes (room temperature 18°C), and the hardening temperature is less than 50°C. Then, it was ground into a cylinder of ∮8×16 mm to make 6 samples. Then put the samples on the pressure testing machine, the head speed is 0.5mm / min, take the compression data of 3mm and 5mm respectively, generate t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com