Technological process of treating sewage into pure water

A sewage and pure water technology, applied in adsorption water/sewage treatment, neutralized water/sewage treatment, reduced water/sewage treatment, etc. The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

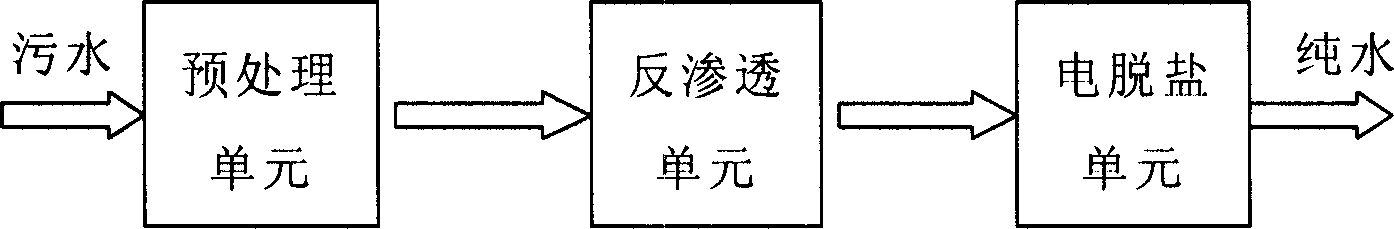

[0027] The industrial wastewater recycling technology based on the membrane separation method has been developed for many years, and the basic process flow has been relatively mature. like figure 2 As shown, the usual sewage treatment system can be divided into three parts: pretreatment unit, reverse osmosis unit and electric desalination unit. Among them, the main function of the reverse osmosis unit and the electric desalination unit is to remove the salt in the water, so they can also be collectively referred to as the desalination unit. The process of making sewage into pure water provided by the present invention is realized based on the overall framework of the above-mentioned sewage treatment system.

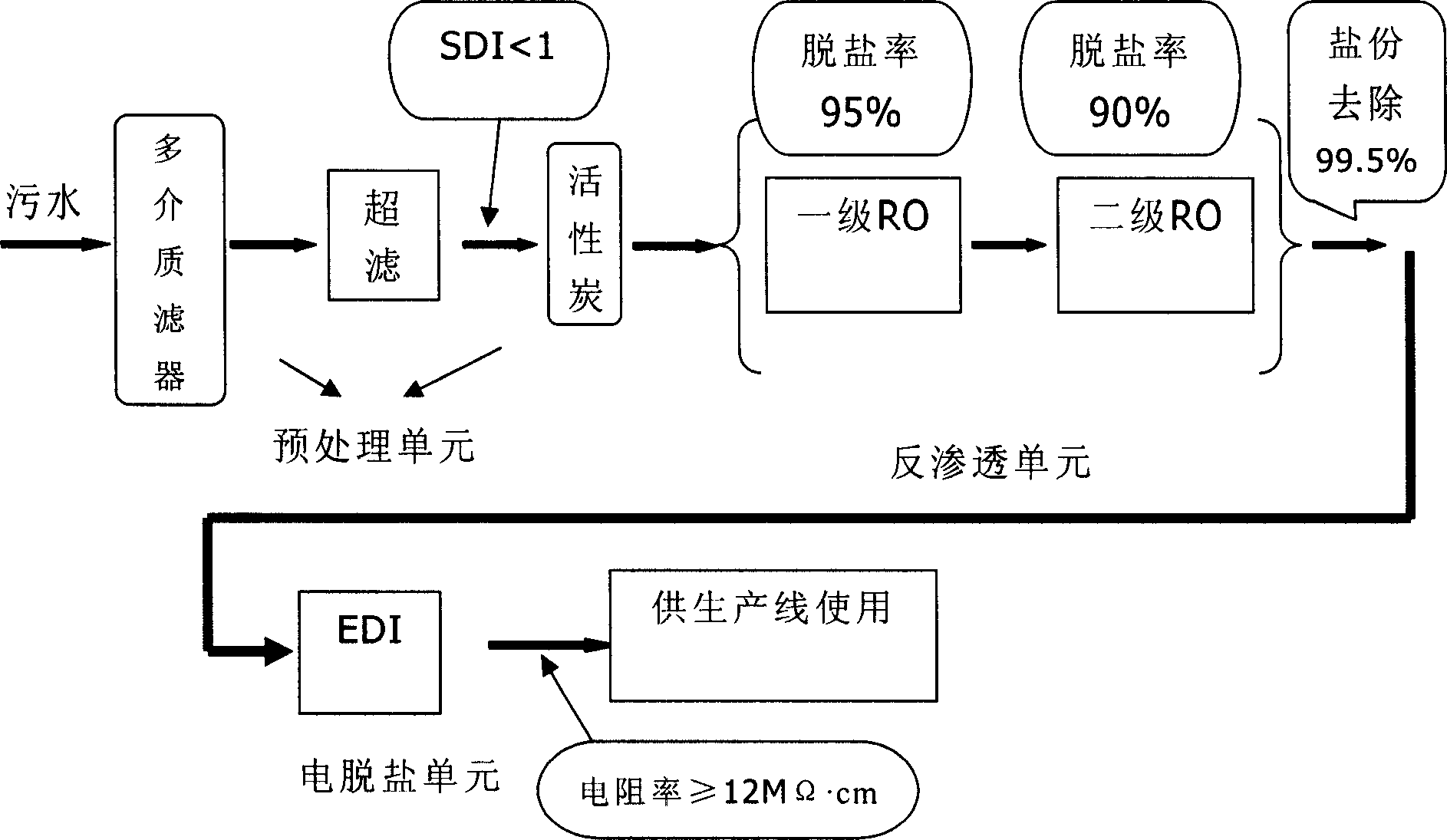

[0028] image 3 It is a schematic diagram of the basic framework of the sewage treatment system used to implement the pure water production process. Figure 4 The basic flow of the pure water production process of the present invention is disclosed.

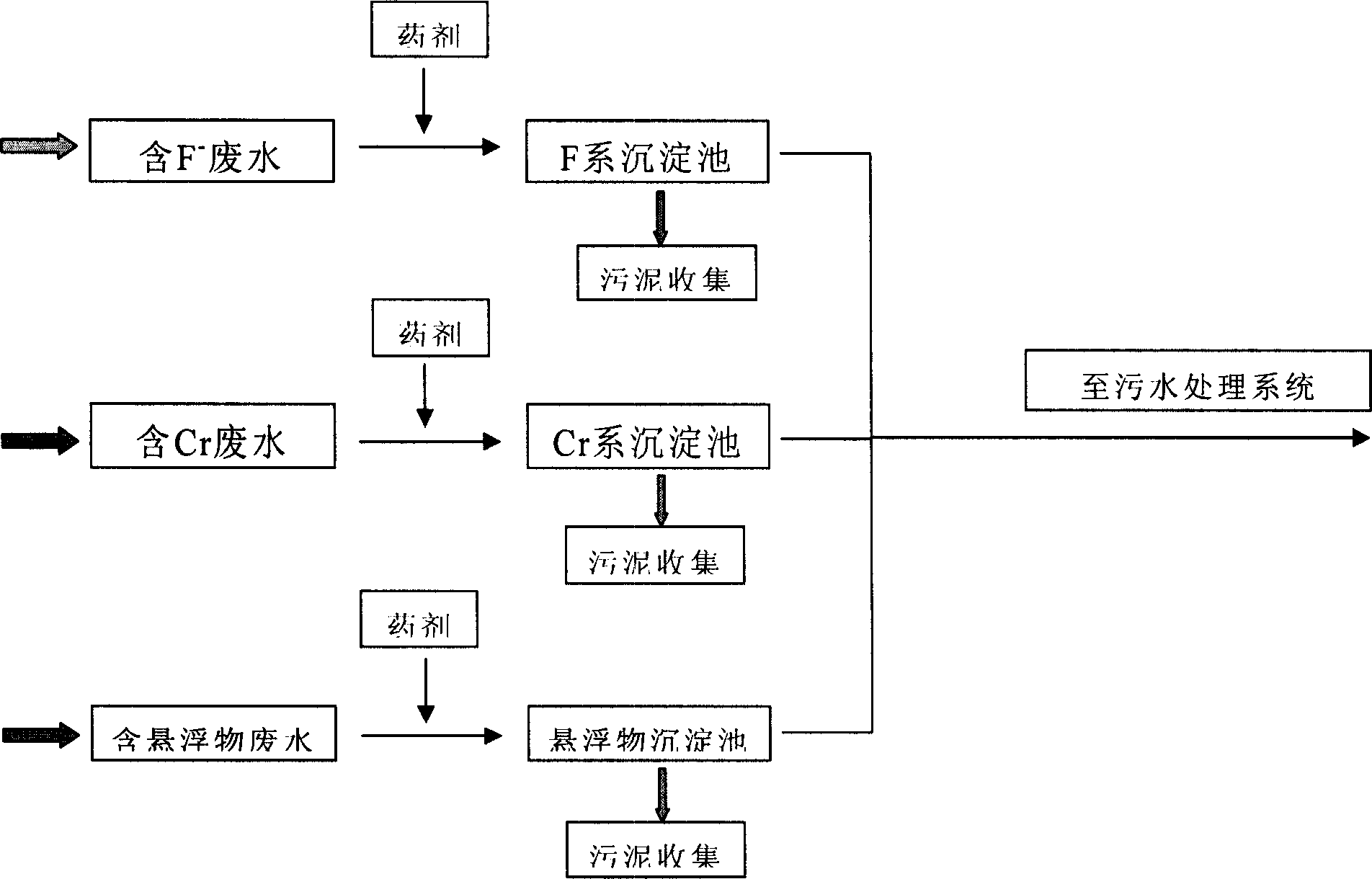

[0029] like F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com