Boiler capable of producing jointly oil, gas and carbon and heat-energy by pyrolyzing biological fuels

A biomass fuel and pyrolysis technology, applied in the boiler field, can solve the problems of lower pyrolysis steam quality, low output, and failure to form an industrial scale, etc., and achieve low pyrolysis energy consumption, simple process flow, and high pyrolysis temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

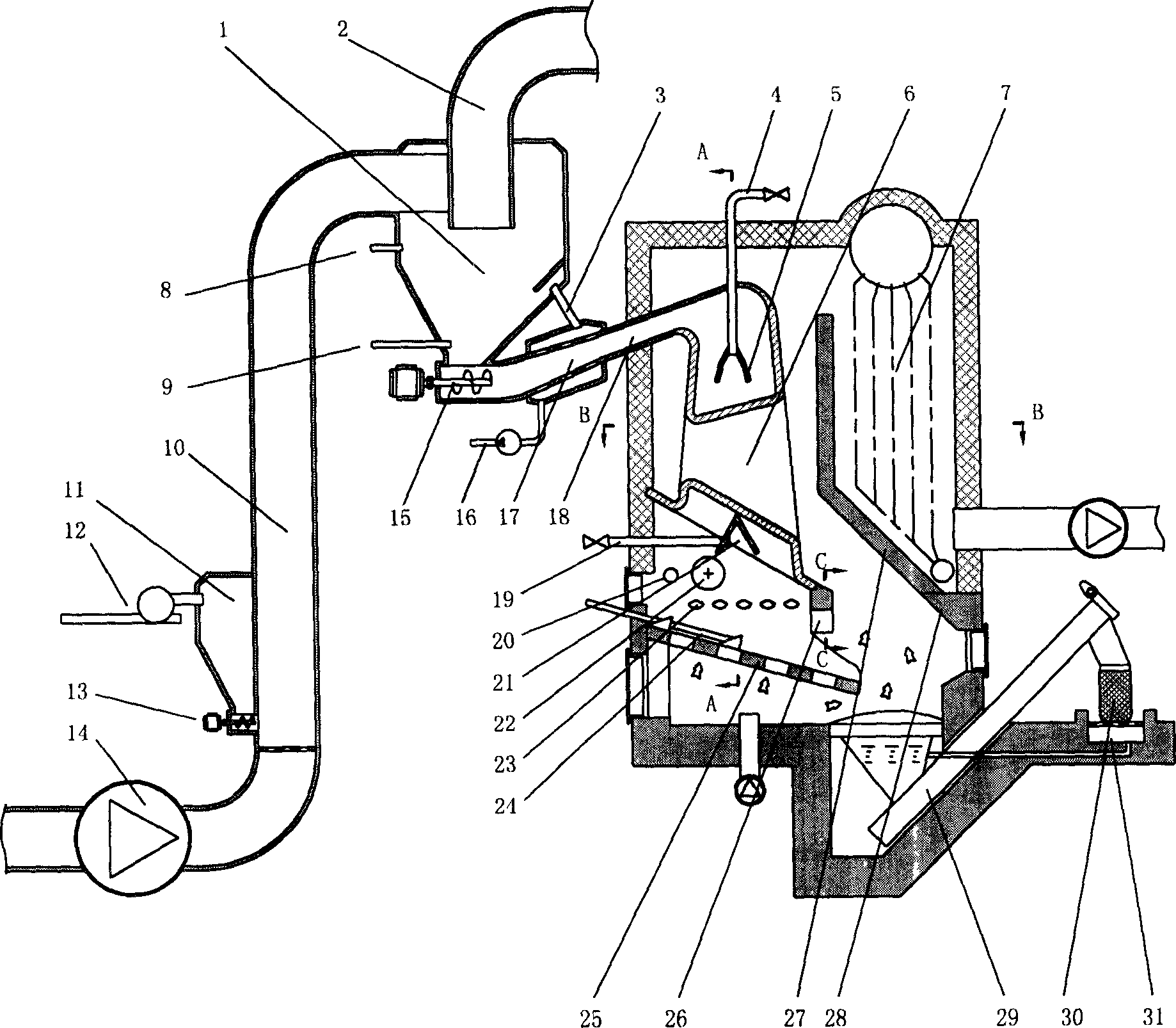

[0040] Use the pulverizer 12 to pulverize the biomass fuel and send it to the buffer bin 11, start the drying fan 14, blow in the drying air (adjust the flue gas to 150°C), start the feeder 13, and send the fuel into the drying (lifting) tower 10, the drying air sends the fuel into the silo 1, and at the same time, it exchanges heat with the fuel to dry the fuel, the drying air is discharged from the drying air outlet 2, the fuel falls into the bottom of the silo, and the screw conveying device is started 15. At the same time, the medium oil with a temperature of about 200°C is sent from the medium oil inlet 9, the medium oil is mixed with the fuel, and pushed into the filter press device 17, the medium oil is immersed in the structure of the fuel and the temperature of the fuel is raised to close to the pyrolysis reaction critical temperature, forming a mixture composed of fuel, gas and medium oil. During the process of propulsion, the gas is discharged from the sieve, and ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com