Bismuthic acid barium-sodium catalyst with visible light respond and production thereof

A technology of photocatalyst and barium bismuthate, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of simple preparation method, good application prospect, and promotion of practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]Weigh 1.264 g of sodium bismuthate, add 32 ml of 0.5 mol / L barium chloride, the molar ratio of barium chloride and sodium bismuthate is 4:1, stir the mixed solution for 30 minutes, and mix well. The mixed suspension is transferred to a stainless steel autoclave lined with polytetrafluoroethylene. The volume of the still is 50 milliliters, and water is added to 45 milliliters, and the degree of filling is 90%. 2 days. The product in the kettle was taken out, washed three times with deionized water and acetone, and dried in a constant temperature oven at 60° C. for 48 hours to obtain a tan barium sodium bismuthate photocatalyst powder. The mass percent of each metal element determined by ICP is: Bi 67.07%, Ba 10.97%, Na 0.63%.

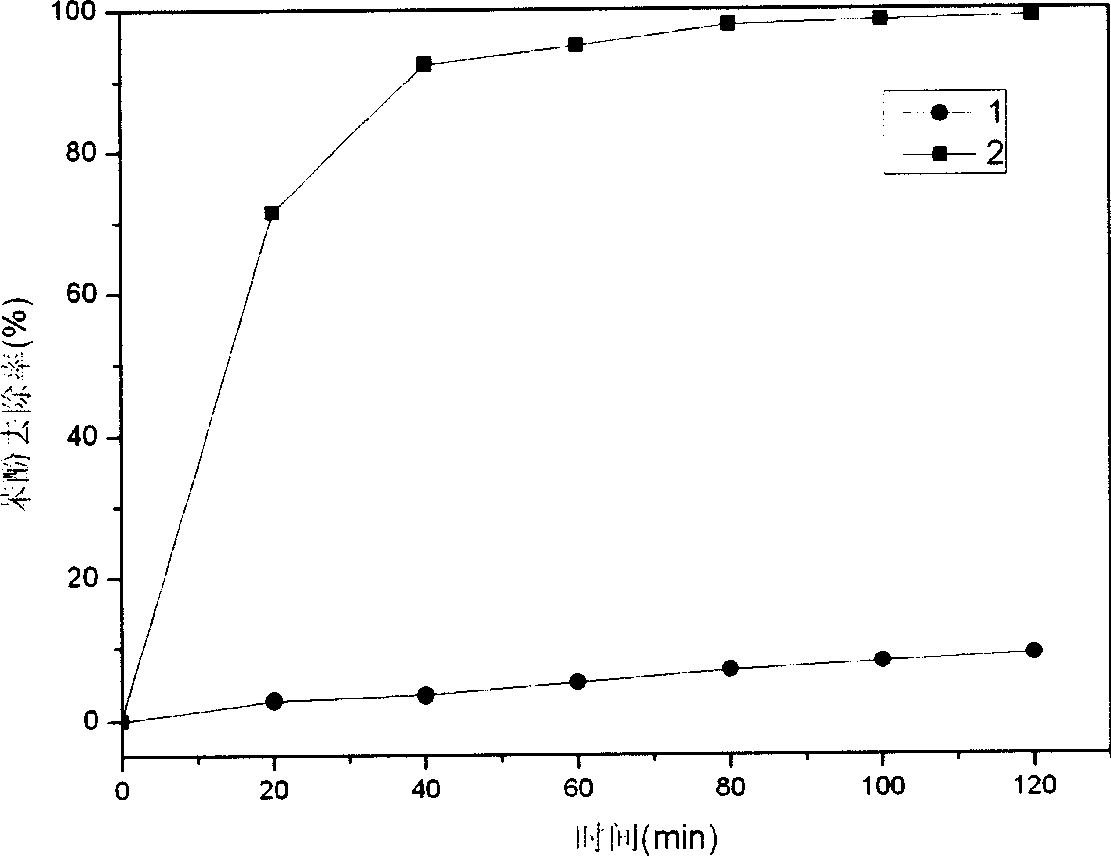

[0025] The photocatalytic performance experiment of the present invention can be tested by degrading phenol in water under visible light. Measuring process is as follows: in the photocatalytic reactor of 250 milliliters, add 200 milliliters conce...

Embodiment 2

[0028] Weigh 1.264 g of sodium bismuthate, add 32 ml of 0.5 mol / L barium chloride, the molar ratio of barium chloride and sodium bismuthate is 4:1, stir the mixed solution for 30 minutes, and mix well. The mixed suspension is transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and the volume of the still is 50 milliliters. Add water to 30 milliliters, and the filling degree is 60%. Tighten the lid of the kettle, and put it into an oven at 90°C to keep 3 days. The product in the kettle was taken out, washed three times with deionized water and acetone, and dried in a constant temperature oven at 60° C. for 48 hours to obtain gray-brown barium sodium bismuthate photocatalyst powder. The mass percent of each metal element determined by ICP is: Bi 63.37%, Ba 9.88%, Na 1.56%. The performance test results of phenol degradation: under the irradiation of visible light with a wavelength greater than 400nm, the phenol removal rate reached 98.2% and the TOC re...

Embodiment 3

[0030] Weigh 1.264 g of sodium bismuthate, add 48 ml of 0.5 mol / liter barium chloride, the molar ratio of barium chloride and sodium bismuthate is 6:1, stir the mixed solution for 30 minutes, and mix well. The mixed suspension was placed in an oil bath and kept at a constant temperature of 90°C for 2 days. The product in the kettle was taken out, washed three times with deionized water and acetone, and dried in a constant temperature oven at 60° C. for 48 hours to obtain brown-gray sodium barium bismuthate photocatalyst powder. The mass percent of each metal element determined by ICP is: Bi 64.18%, Ba 8.89%, Na 1.57%. The performance test results of phenol degradation: under the irradiation of visible light with a wavelength greater than 400nm, the phenol removal rate reached 93.5% and the TOC removal rate reached 90.4% within 120 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com