Process for producing diesel oil from wastes in agricultural and forest industries

A technology for forestry waste and biodiesel, which is applied in the field of biodiesel production, can solve the problems of poor source of raw materials, difficult to popularize and apply, and high cost, and achieve the effects of easy availability of raw materials, economic benefits, and short construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

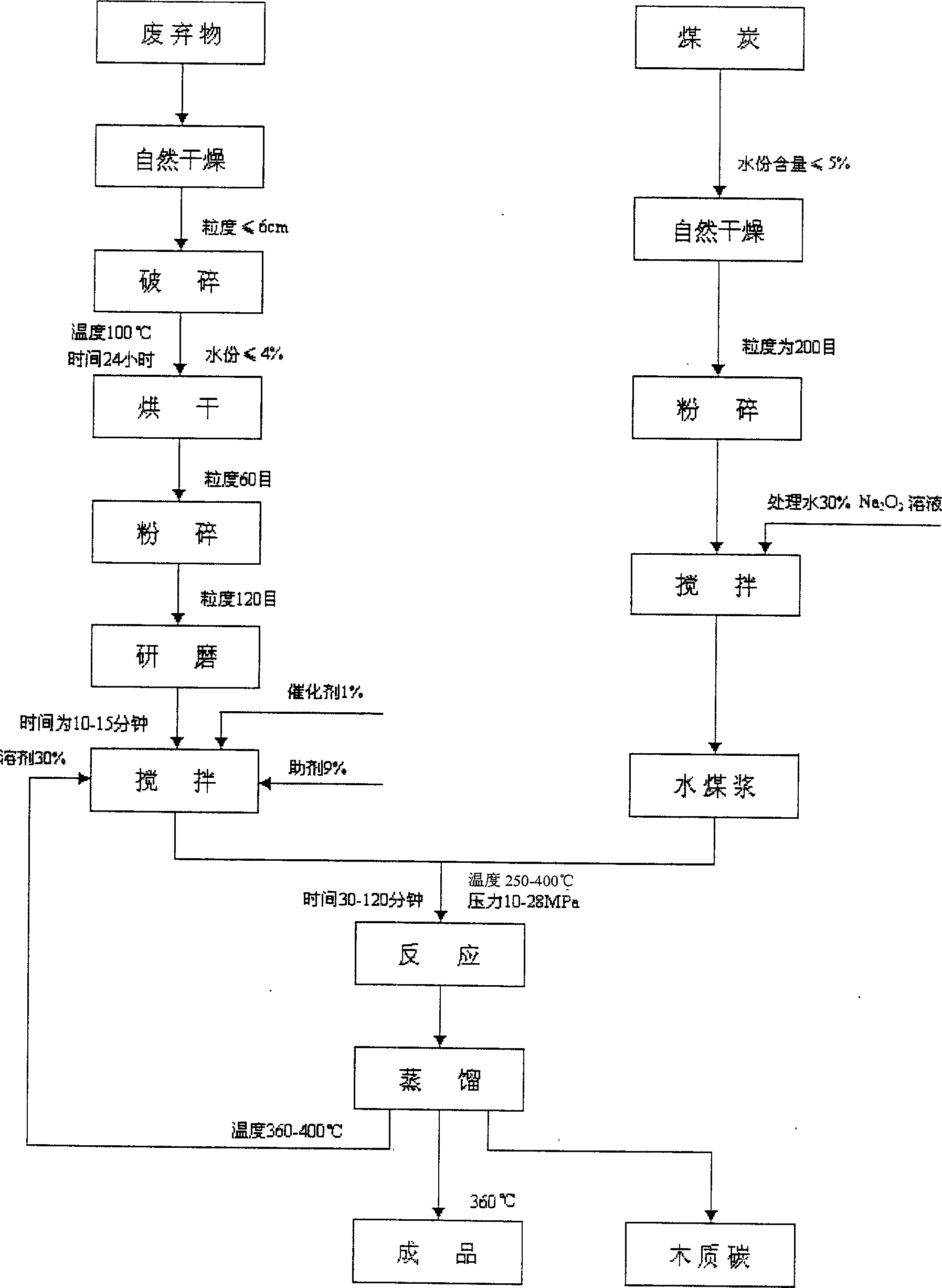

Image

Examples

Embodiment 1

[0019] Production of biodiesel. First prepare enough needed various materials, then by the composition formula provided by the present invention and its content (weight %) ratio, promptly agriculture, forestry waste 55, solvent 30, auxiliary agent 9.0, catalyzer 1.0, additive 5.0 weigh all Various materials are needed, use waste peanut shells or sawdust 550kg, the first operation of the equipment, solvent use 300kg refined anthracene oil, auxiliary agent is methanol 90kg, catalyst aluminum chloride 10kg, additive CWS 50kg; agricultural and forestry waste peanuts Hull or sawdust, first of all pretreatment, after the waste is naturally dried, it is crushed to a particle size of ≤6cm, then transferred to the greenhouse for drying, at a room temperature of 100°C, dried for 24 hours, and the moisture content is ≤4%, and then it should be subjected to high-performance The pulverizer is crushed, the particle size is 60 mesh, and the particle size after entering the grinder is 120 mes...

Embodiment 2

[0022] Prepare the required raw materials to produce biodiesel. According to the component weight (%) ratio that the present invention provides: agriculture, forestry waste 50, solvent 30, auxiliary agent 9, catalyzer 1, additive 10, weigh various materials, waste adopts cottonseed hull or treetop 500kg, helps The solvent is 90kg of methanol, the catalyst is 10kg of aluminum chloride, the solvent is 300kg of distillate oil at 360-400℃ for recycling, and the additive is 100kg of coal water slurry; after pretreatment, the waste is transferred to the agitator together with the solvent, additive and catalyst , stirred for 10 minutes, fully stirred evenly and then transferred to the reaction process. First, the coal-water slurry was input into the reactor with a high-pressure pump, and then the uniformly stirred waste and all materials were input into the reactor; the reaction process was heated to 280 ° C, Reaction pressure 15MPa, reaction time 110 minutes; Other each operation an...

Embodiment 3

[0024] According to the component formulation and the weight (%) ratio provided by the invention, the raw materials are prepared to produce the biodiesel.

[0025] According to the component formula (weight %) ratio, agriculture, forestry waste 45, solvent 30, auxiliary agent 9, catalyst 1, coal water slurry 15; Weigh each material, get corncob or branch 450kg, auxiliary agent cetyl alcohol 90kg, catalyst aluminum chloride 10kg, coal water slurry 150kg, solvent 300kg, take the distillate oil from the distillation process at 360-400°C for recycling; after various materials are pretreated, waste, solvent, additives, and catalysts can be put into Fully stir in the agitator, and the stirring time is 15 minutes; before transferring to the reaction process, the coal-water slurry should be input into the reactor with a high-pressure pump, and then the fully stirred waste and its mixture should be input into the reactor; The temperature was 300° C., the reaction pressure was 16 MPa, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com