Production of nanometer wire with cadmium sulfide

A nanowire and cadmium sulfide technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of slow application process of nanowires, unverifiable performance, and unguaranteed purity, and achieve the goal of using The effect of simple equipment, uniform size distribution and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] 1) Put 1mmol of cadmium chloride, 3mmol of thiourea, and 0.1mmol of diphenylthizone into a reaction kettle lined with polytetrafluoroethylene, then add 50ml of hexamethylenediamine, and close the reaction kettle;

[0017] 2) Keep the reactor at 180°C for 144 hours;

[0018] 3) Take out the yellow precipitate in the reactor, then alternately and repeatedly wash with deionized water and ethanol;

[0019] 4) The cleaned product is fully dried in a vacuum oven at 50°C.

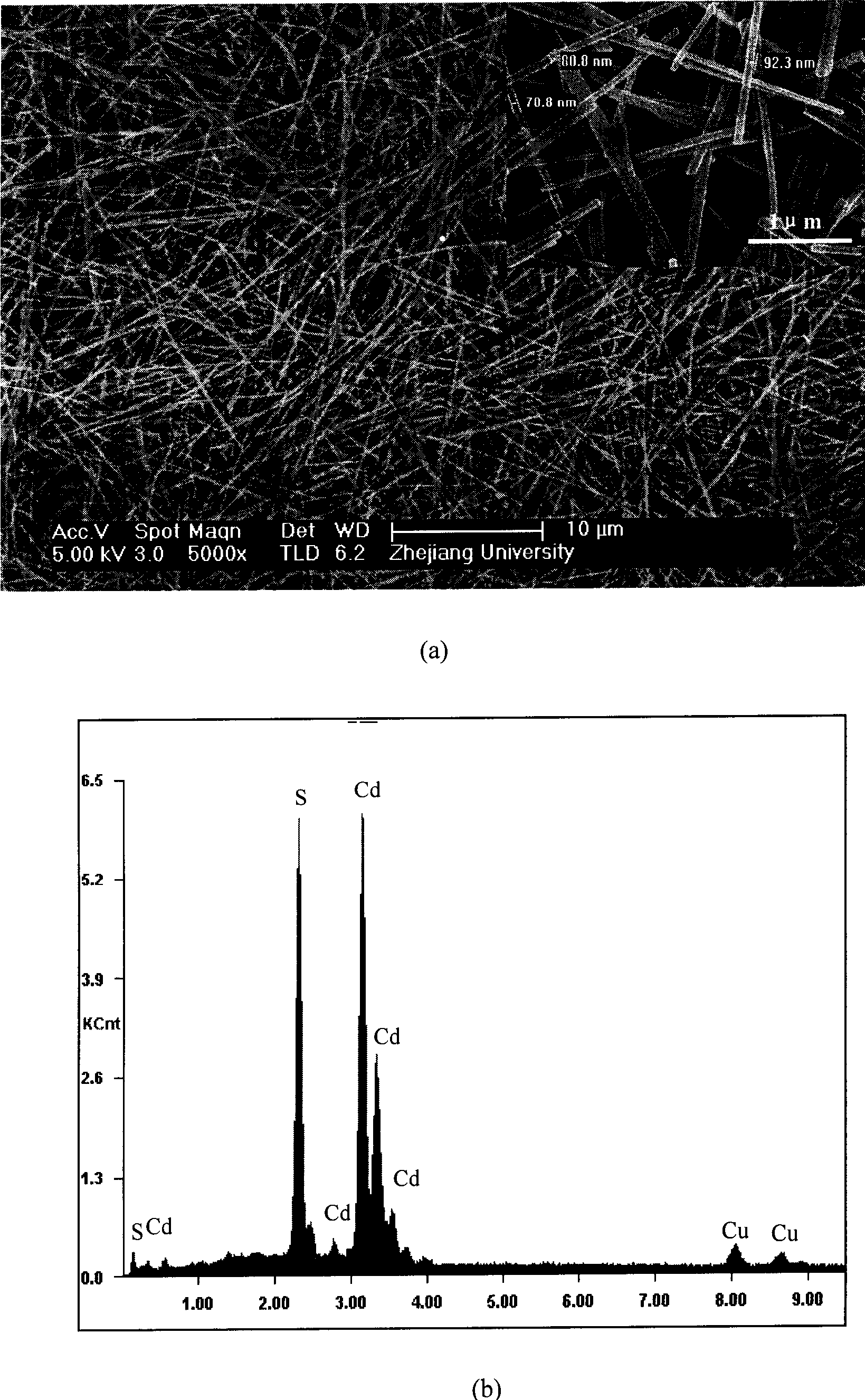

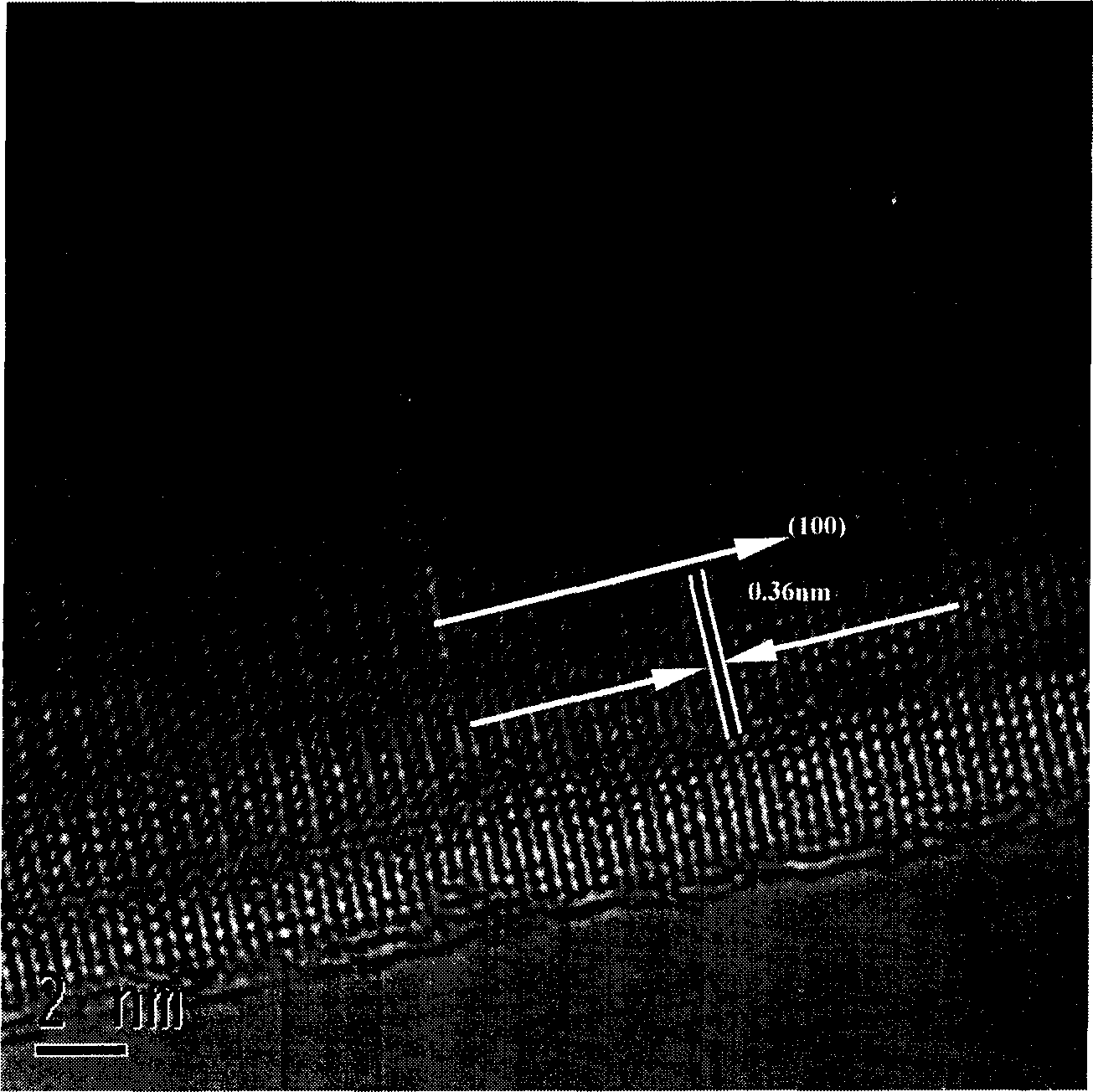

[0020] The SEM photographs and component analysis of the prepared CdS nanowires are as follows: figure 1 As shown, the diameter distribution of CdS nanowires is very uniform from the enlarged image in the upper right corner of the SEM image. It can be seen from the composition analysis spectrum that the purity of CdS nanowires is extremely high, and the weight percentages of S and Cd are 22.39% and 77.61%, respectively. The peak of Cu is produced by the copper pillar of the sample stage. High-resolution ...

example 2

[0022] The steps are the same as in Example 1, except that the thiourea added in step 1) is 2.5 mmol, and the reaction temperature of the reactor is 250° C. The diameter distribution of the prepared CdS nanowires is also very uniform, and the weight percentages of S and Cd are 20.42% and 79.58%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com