Lithium ion battery with high multiplying factor

A lithium-ion battery, high-rate technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve problems such as no discharge, and achieve the effects of improving discharge rate, good safety, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Implementation 1

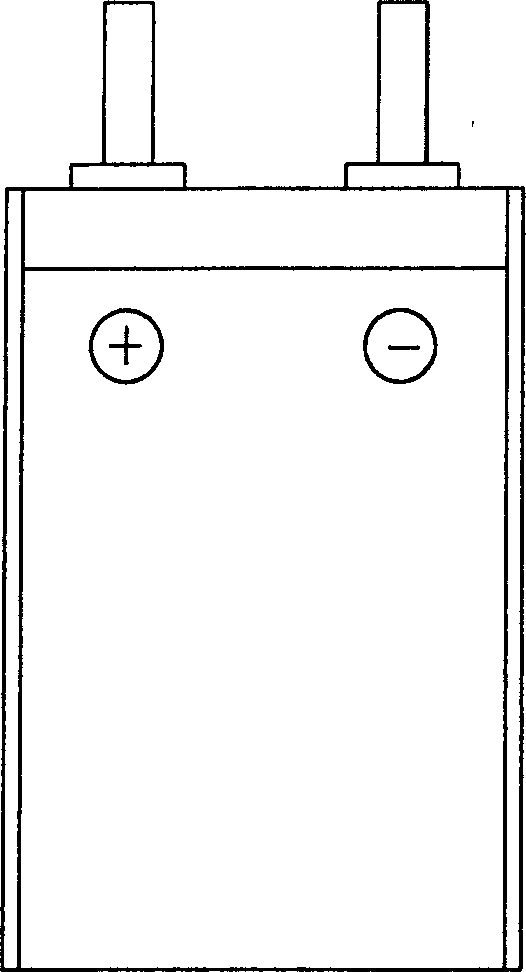

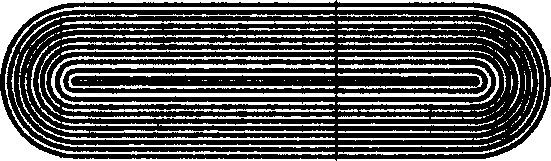

[0032] Taking the manufacturing process of 100-2500mAh high-rate lithium-ion battery as an example to illustrate, the battery structure is as follows: figure 1 As shown, the production of the battery is carried out as follows:

[0033] The preparation of positive electrode slurry: N-dimethylpyrrolidone (NMP) was used as solvent, and the active material was lithium cobaltate (LiCoO 2 ), the conductive agent is a mixture of super conductive carbon black (Super P) and conductive graphite (KS-6), the binder is polyvinylidene fluoride (PVDF), and NMP is based on the particle size and particle size distribution of lithium cobaltate used etc. are added, and the addition ratio is between 45% and 75%. The ratio used in this embodiment is: LiCoO 2 :SuperP:KS-6:PVDF:NMP=80:7:7:6:55. First LiCoO 2 , Super P, and KS-6 are dispersed and mixed under the protection of inert gas, and the conductive agent is evenly dispersed in LiCoO 2 Particle surface; then add P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compaction thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com