Excimer lamp

An excimer lamp and discharge vessel technology, which is applied to discharge lamps, gas discharge lamps, and parts of gas discharge lamps, etc., can solve the problems that the getter cannot obtain the heating effect, cannot obtain sufficient getter effect, etc. Pursuing high efficiency, simple structure, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

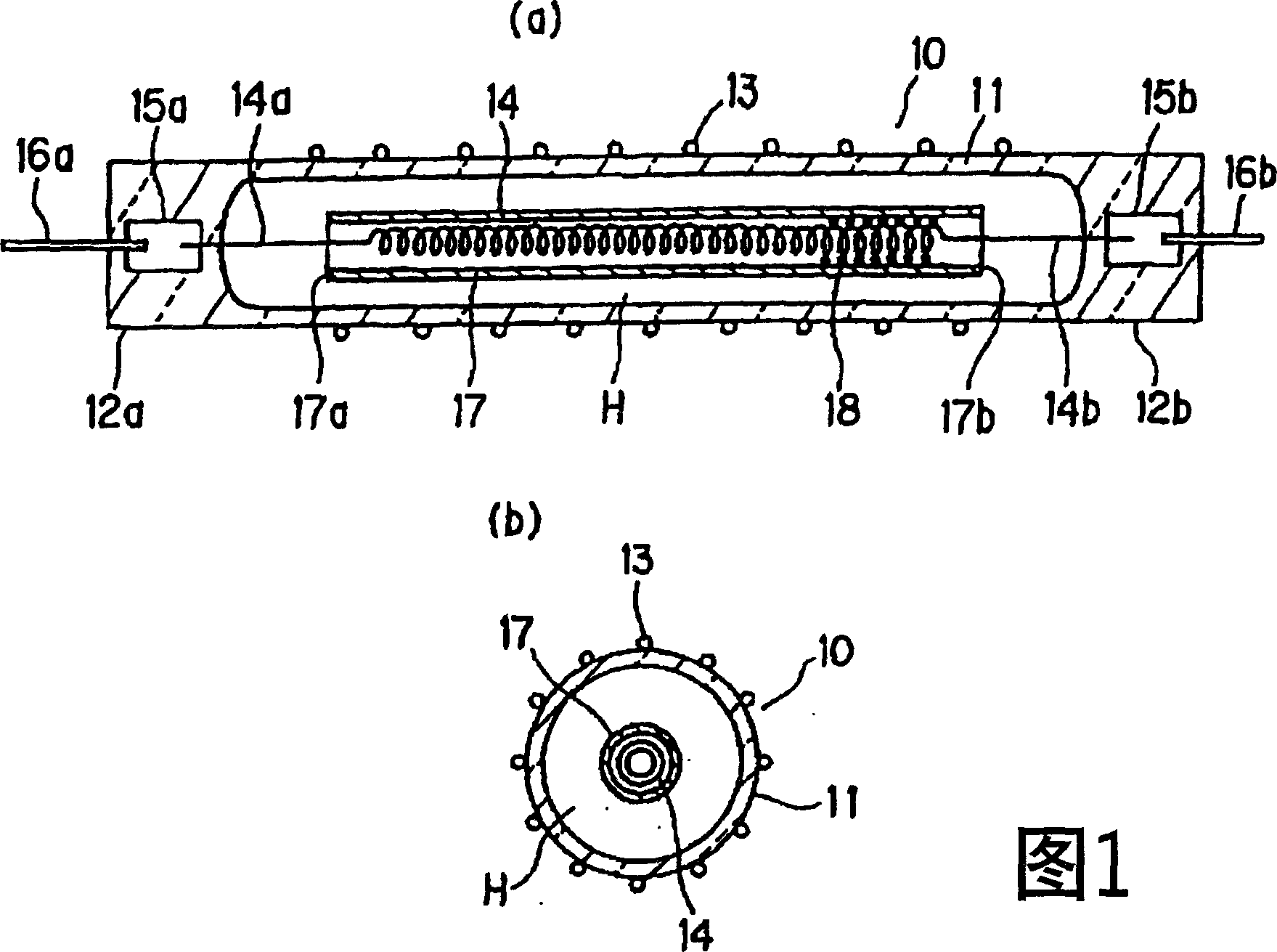

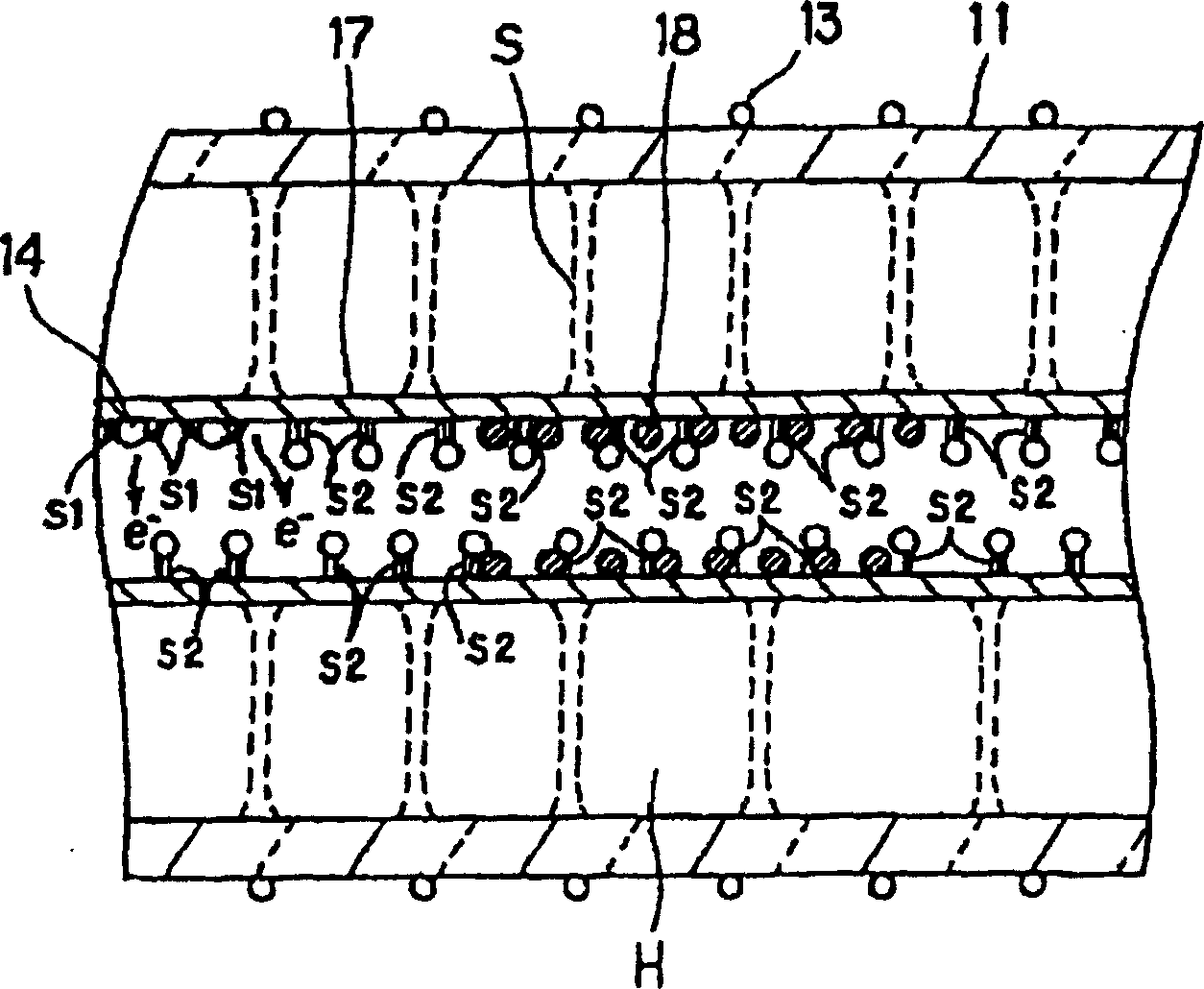

[0089] The excimer lamp A1 having the structure shown in FIG. 1 was produced under the following conditions.

[0090] Discharge vessel (10): total length about 1500mm; inner tube (17): material: synthetic quartz glass, inner diameter: about 14mm, outer diameter: about 16mm (wall thickness 1mm); outer tube (11): material: synthetic quartz glass , outer diameter: 26mm, inner diameter: 24mm (wall thickness 1mm); inner electrode (14): material: tungsten, wire bundle diameter: 0.5mm, coil diameter: 13.5mm, axial distance: 5mm, overall length: 1300mm (260 circle); outer electrode (13): material: stainless steel, discharge gas: xenon (enclosed pressure 20kPa).

[0091] As a getter, a metal wire made of tantalum and having a diameter of 0.2 mm was wound around the inner electrode at a pitch of 100%, and fixed by winding 50 mm in the axial direction.

Embodiment 2

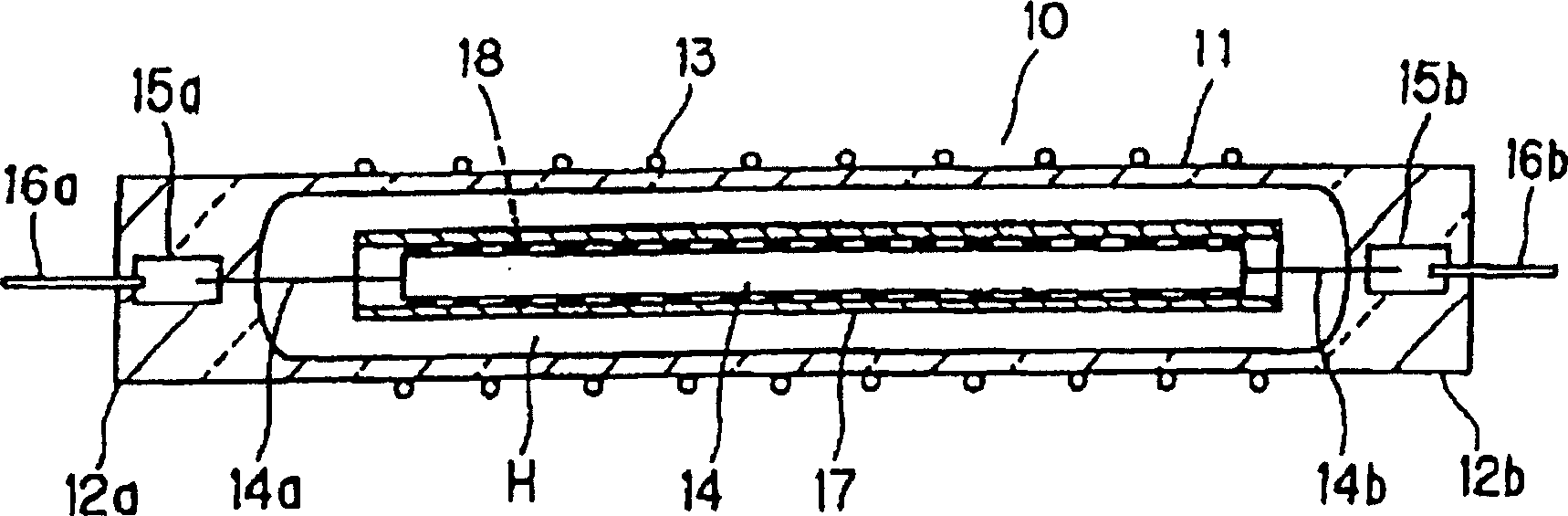

[0093] Made under the following conditions Figure 4 Excimer lamp A2 of the configuration shown.

[0094] Discharge vessel (10): total length about 1500mm; inner tube (17): material: synthetic quartz glass, inner diameter: about 14mm, outer diameter: about 16mm (wall thickness 1mm); outer tube (11): material: synthetic quartz glass , outer diameter: 26mm, inner diameter: 24mm (wall thickness 1mm); inner electrode (14): material: titanium, wire bundle diameter: 0.5mm, coil diameter: 13.5mm, axial distance: 5mm, overall length: 1300mm (260 circle); outer electrode (13): material: stainless steel, discharge gas: xenon (enclosed pressure 20kPa).

[0095] In Example 2, an internal electrode made of titanium acts as a getter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Full length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com