Three level inverter control system and method

A technology of three-level inverter and control method, which is applied in the direction of converting irreversible DC power input into AC power output, etc., which can solve the problem that the control signal cannot be changed quickly, the digital implementation has a large amount of calculation, and the system has poor rapidity, etc. problem, to achieve the effect of overcoming the difficulty of low output voltage control, good real-time performance, and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0038] (I. Overview

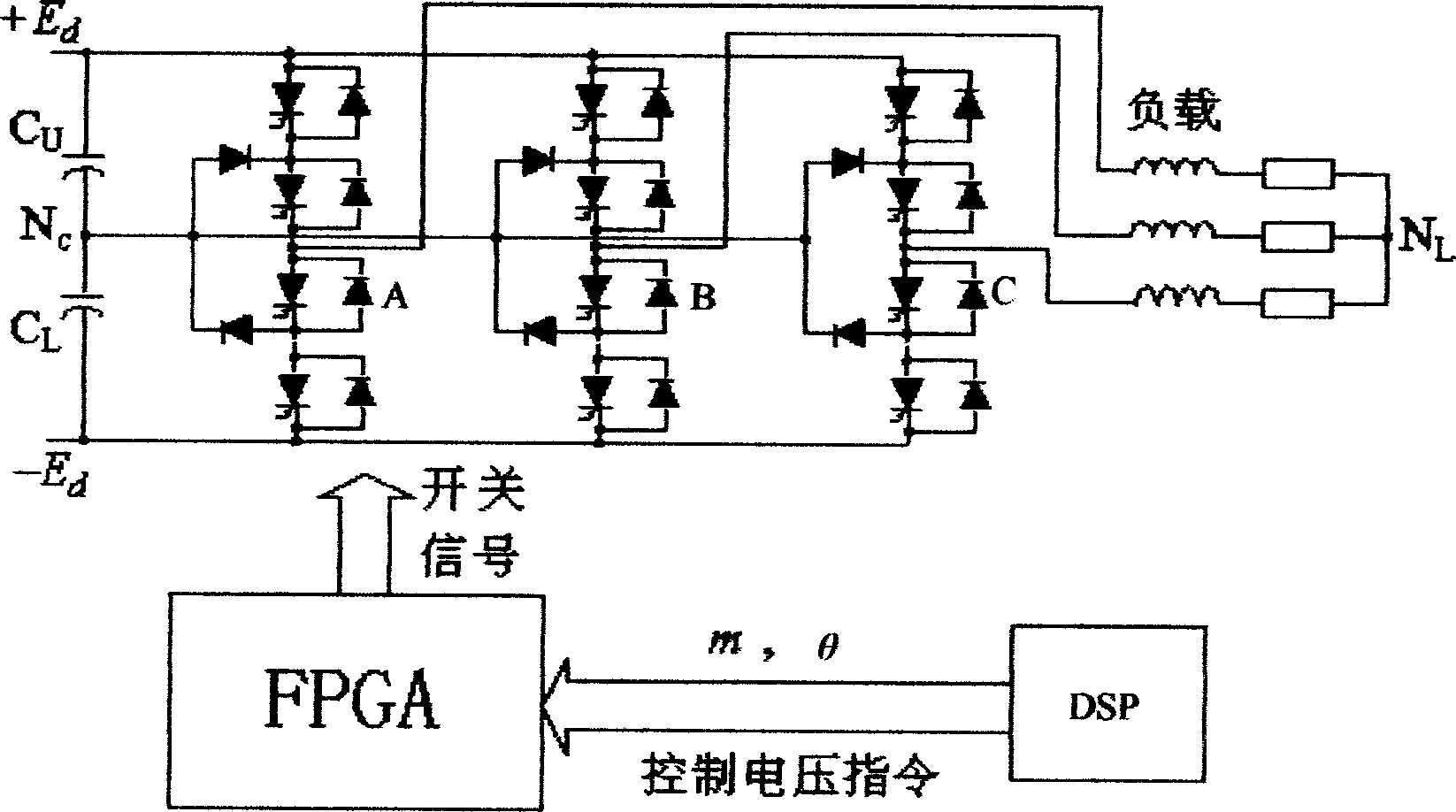

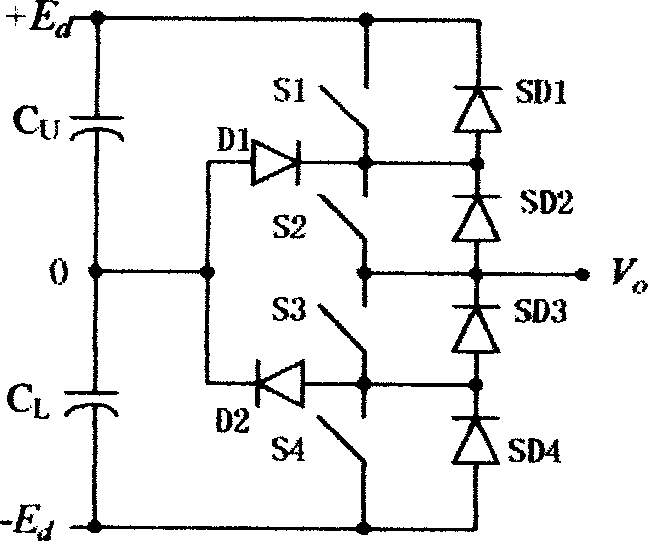

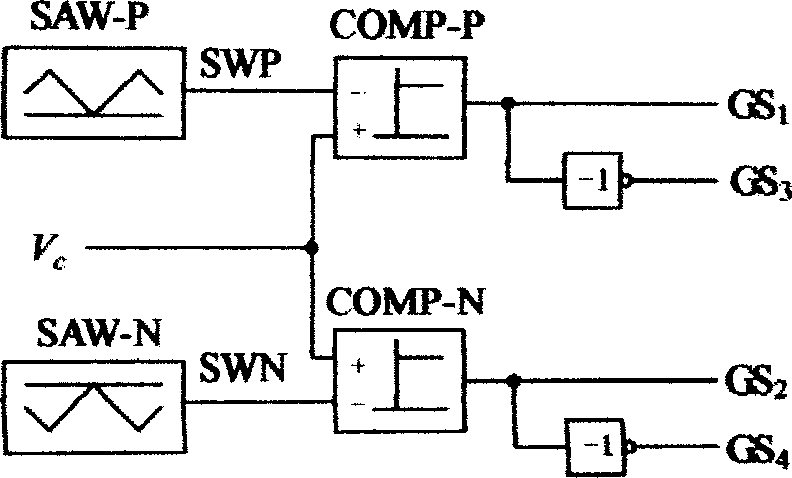

[0039] The main circuit of the three-level inverter is shown in figure 1 . Each phase bridge arm is composed of 4 switching devices and 2 clamping diodes, and the output has three working states: "+"—+E d ; "0"—0V; "-"——E d . Thus, a three-valued switch function can be defined, such as S A (1, 0, -1) means the three voltage states of the AC side voltage of phase A, and the conditions of each phase are the same, so it is deduced that the three-phase output of the three-level inverter has a total of 3 3 = 27 states, defined according to the voltage space vector

[0040]

[0041] where S A , S B and S C is the switching function of A, B, C three-phase output state, S m =1 represents the "+" state, 0 represents the "0" state, and -1 represents the "-" state. These 27 states constitute a total of 19 voltage vectors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com