Fluorine-contd. linkage polyether demulsification agent and its prepn. method

A cross-linked polyether demulsifier and demulsifier technology, applied in the dehydration/demulsification of hydrocarbon oil, petroleum industry, etc., can solve the problem of processing load reduction, achieve the effect of fast dehydration speed, low dehydration temperature and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

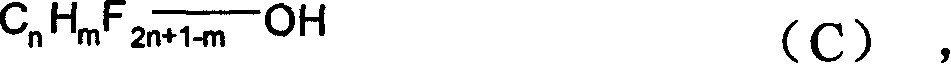

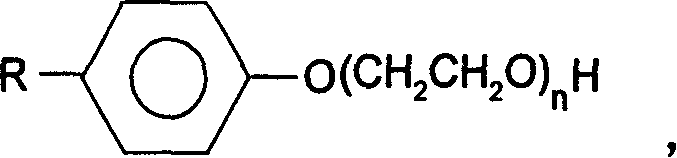

[0029] A fluorine-containing cross-linked polyether demulsifier, the raw material components and weight percentages of the demulsifier are as follows: (A) 1%, (B) 97%, (E) cross-linking agent 2%; A) is tetrafluoropropanol, the block polyether (B), its structural formula is:

[0030] R-O-(CH 2 CH 2 O) n H, said n is 1-18,

[0031] The (E) cross-linking agent is toluene diisocyanate (TDI).

[0032] The preparation method of the above-mentioned fluorine-containing cross-linked polyether demulsifier is to polymerize the tetrafluoropropanol (A) and the block polyether (B) under the action of the cross-linking agent toluene diisocyanate (TDI) (E). become.

[0033]The preparation method of the block polyether (B) includes the following process steps: pump the initiator into the polymerization reactor, then raise the temperature of the material to 100-120° C., and remove light components and water by vacuuming. In the material from which light components and moisture have been r...

Embodiment 2

[0035] A fluorine-containing cross-linked polyether demulsifier, the raw material components and weight percentages of the demulsifier are as follows: (A) 20%, (B) 70%, (E) cross-linking agent 10%, the ( A) is perfluoroacetic acid, described block polyether (B), its structural formula is:

[0036]

[0037] The (E) cross-linking agent is polyalkylene polyisocyanate (PAPI).

[0038] The preparation method of the above-mentioned fluorine-containing cross-linked polyether demulsifier and the preparation method of the block polyether (B) are the same as in Example 1.

Embodiment 3

[0040] A fluorine-containing cross-linked polyether demulsifier, the raw material components and weight percentages of the demulsifier are as follows: (A) 45%, (B) 40%, (E) cross-linking agent 15%, described ( A) is hexafluorobutanol, the block polyether (B), its structural formula is:

[0041]

[0042] The (E) cross-linking agent is diphenylmethane-4,4'-diisocyanate (MDI).

[0043] The preparation method of the above-mentioned fluorine-containing cross-linked polyether demulsifier and the preparation method of the block polyether (B) are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com