Process and equipment for co-gasification of biomass and coal

A biomass and co-gasification technology, which is applied in the direction of granular/powdered fuel gasification, etc., can solve the problems of high volatile content of biomass, low reaction temperature, and affecting the use of gas, so as to achieve simple control, improve the ecological environment, and ensure The effect of energy supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

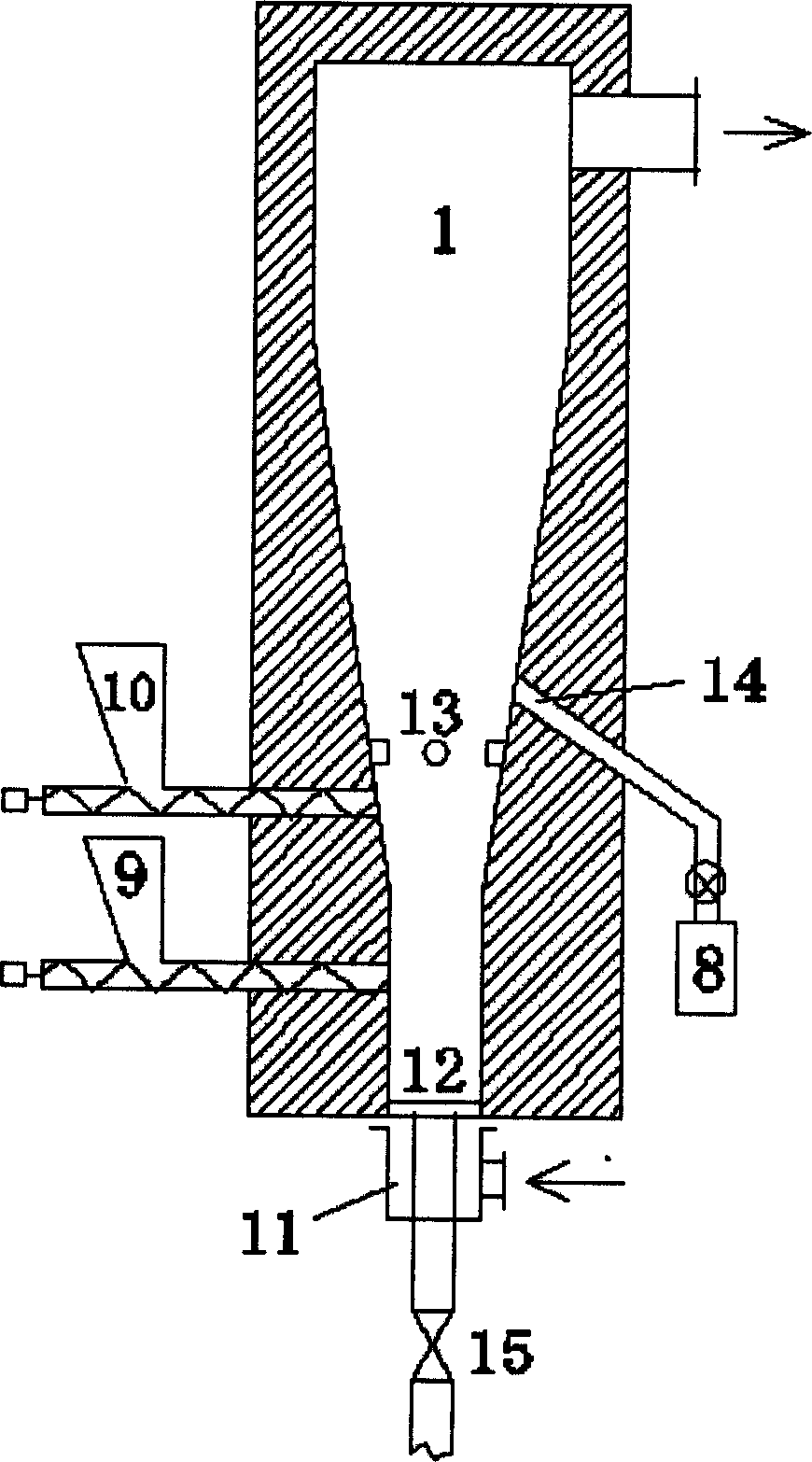

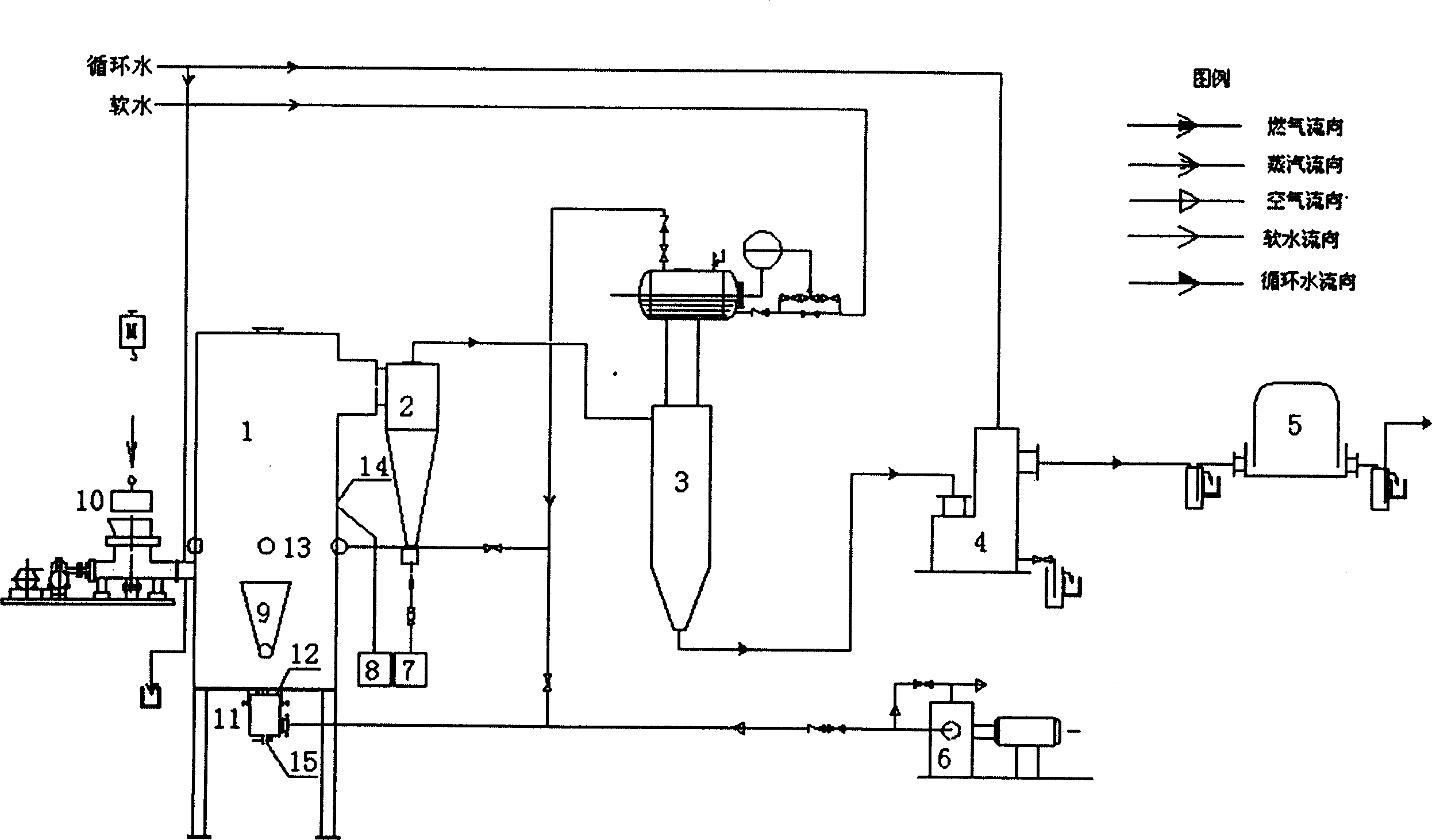

[0014] Such as figure 1 As shown, the process uses air and water vapor as gasification agents, and the raw coal of 0-6mm is fed into the biomass in a certain proportion through the screw feeder (9) and the biomass of 0-10mm is passed through the screw feeder (10). In the fluidized bed gasification furnace (1), the air enters the biomass fluidized bed gasification furnace (1) from the Roots blower (6) through the air chamber (11) through the air distribution plate (12), so that the biomass in the furnace Substances and coal undergo partial oxidation, pyrolysis and gasification reactions in a fluidized bed state.

[0015] Since the reaction has an exothermic reaction and an endothermic reaction, when the two reactions are in thermal equilibrium, the bed temperature is in a stable state. The temperature is adjusted according to the ratio parameters of air volume, water vapor volume and biomass / coal volume to reach a predetermined temperature. Generally, the adjustment range of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com