Low temp chemical gaseous deposition for preparing silicon nitride thin film

A technology of vapor phase deposition and low-temperature chemistry, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as difficult film deposition and thermal CVD application limitations, and achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

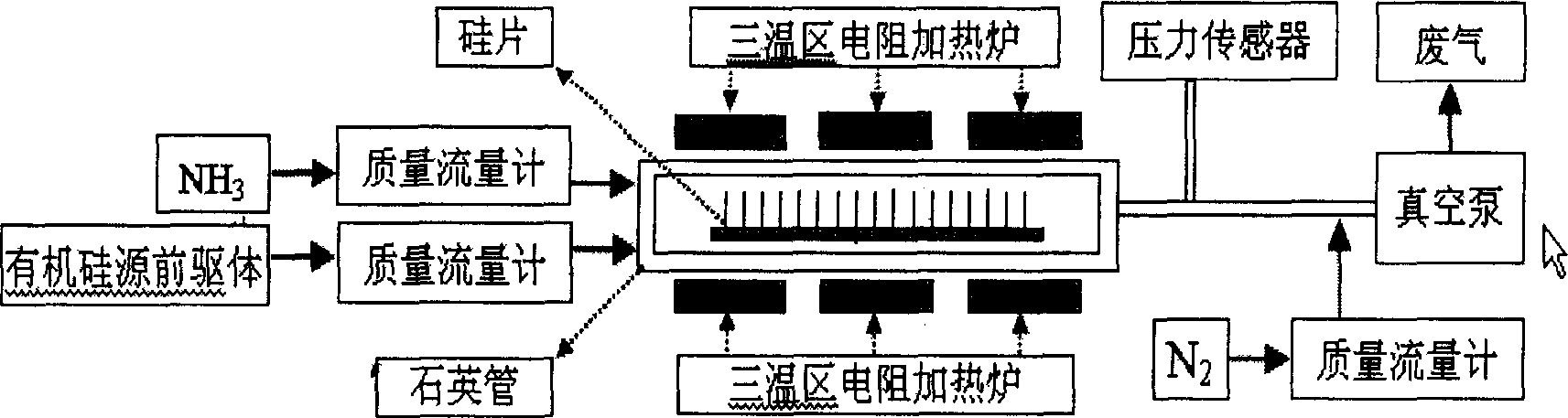

Method used

Image

Examples

Embodiment 1

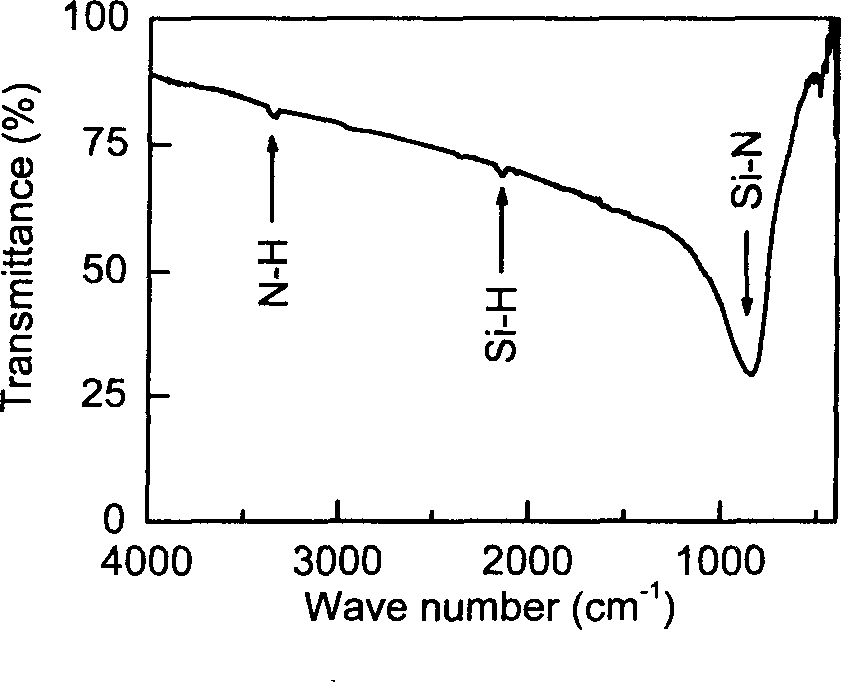

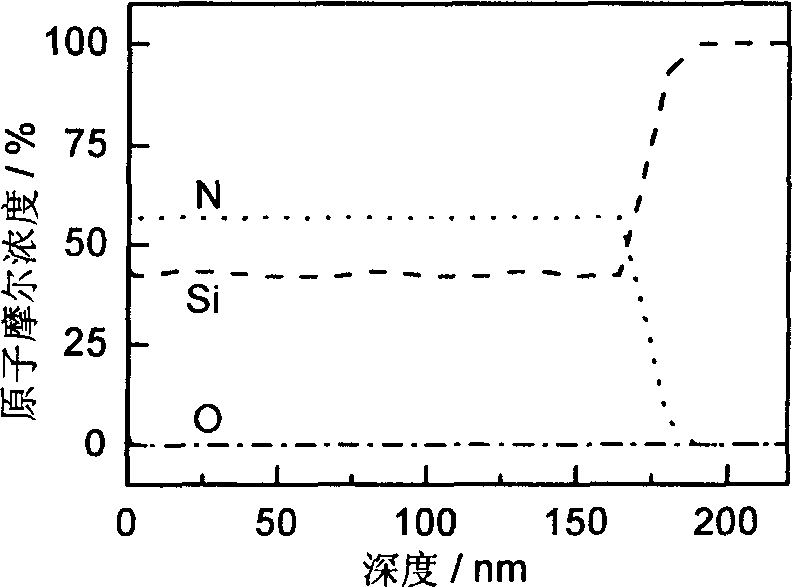

[0022] Insert clean 2-inch monocrystalline silicon wafers (p-type, 110) upright on the quartz boat, load 80 silicon wafers at a time, place them at equal intervals, and the distance between the wafers is 8mm, and place the loaded quartz boat on the figure 1 At the central position of the hot-wall tubular quartz reactor, turn on the vacuum pump and pump it down to below 0.5Pa. The temperature at the central position of the reactor, that is, the substrate temperature, is 700°C. In order to improve the uniformity of the deposited film, a resistance heating furnace ( That is, the temperature gradient between the inlet and outlet of the aforementioned diffusion furnace) is 20°C, and the deposition can only begin after the temperature is controlled to ±1°C. Electronic grade high purity NH 3 as N source, with [(C 2 h 5 ) 2 N] 3 SiCl is the source of Si, the flow rates of the two are 80 and 10 sccm respectively, and high-purity N 2 (99.999%) is the carrier gas used to adjust the ...

Embodiment 2

[0025] With high purity NH 3 as N source, with (C 2 h 5 NH) 3 SiCl is the Si source, the flow rates of the two are 80 and 10 sccm respectively, and the temperature at the center of the reactor is 680°C, and the rest are the same as in Example 1. Prepared SiN x The content of H in the film is about 4.2at%, nearly stoichiometric SiN x C and O are absent from the film (x=1.30).

Embodiment 3

[0027] With high purity NH 3 as N source, with [(C 3 h 7 ) 2 N] 2 SiH 2 Si source, the flow rates of the two are 80 and 10 sccm respectively, the temperature at the center of the reactor is 750°C, and the rest are the same as in Example 1. Prepared SiN x The content of H in the film (x=1.28) is about 5.3 at%, free of C and O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com