Thin wall drilling bit

A kind of drill bit and thin-walled technology, which is applied in the field of thin-walled drill bits, can solve problems such as easy accidents, poor ability to resist torque, and reduce the joint surface, so as to improve the joint strength of the drill bit, increase the safe service life, and increase the welding capacity. binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following are non-limiting examples of the invention.

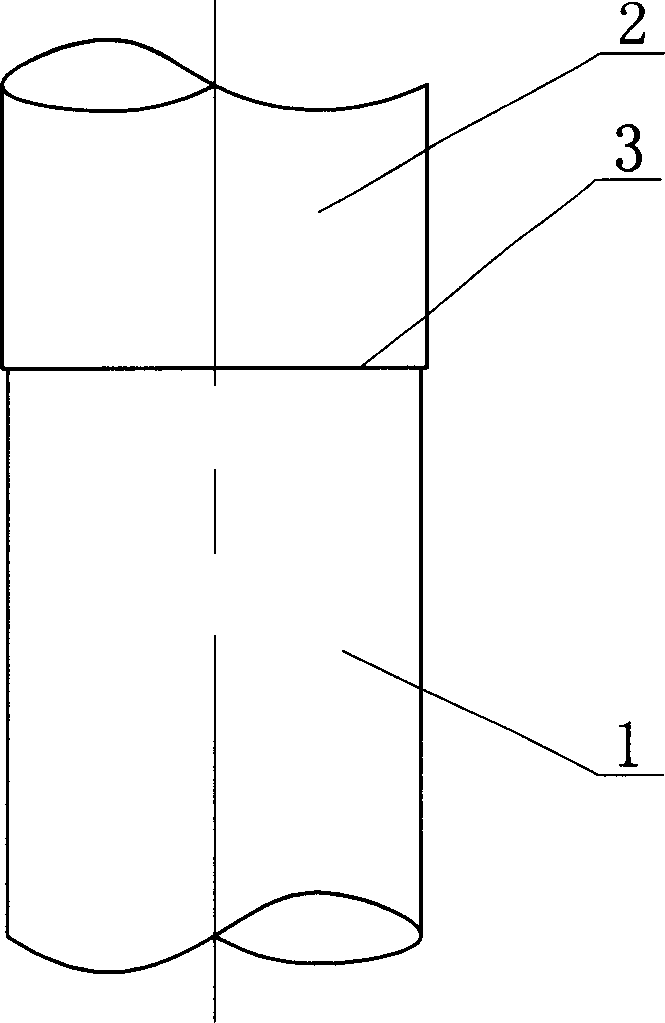

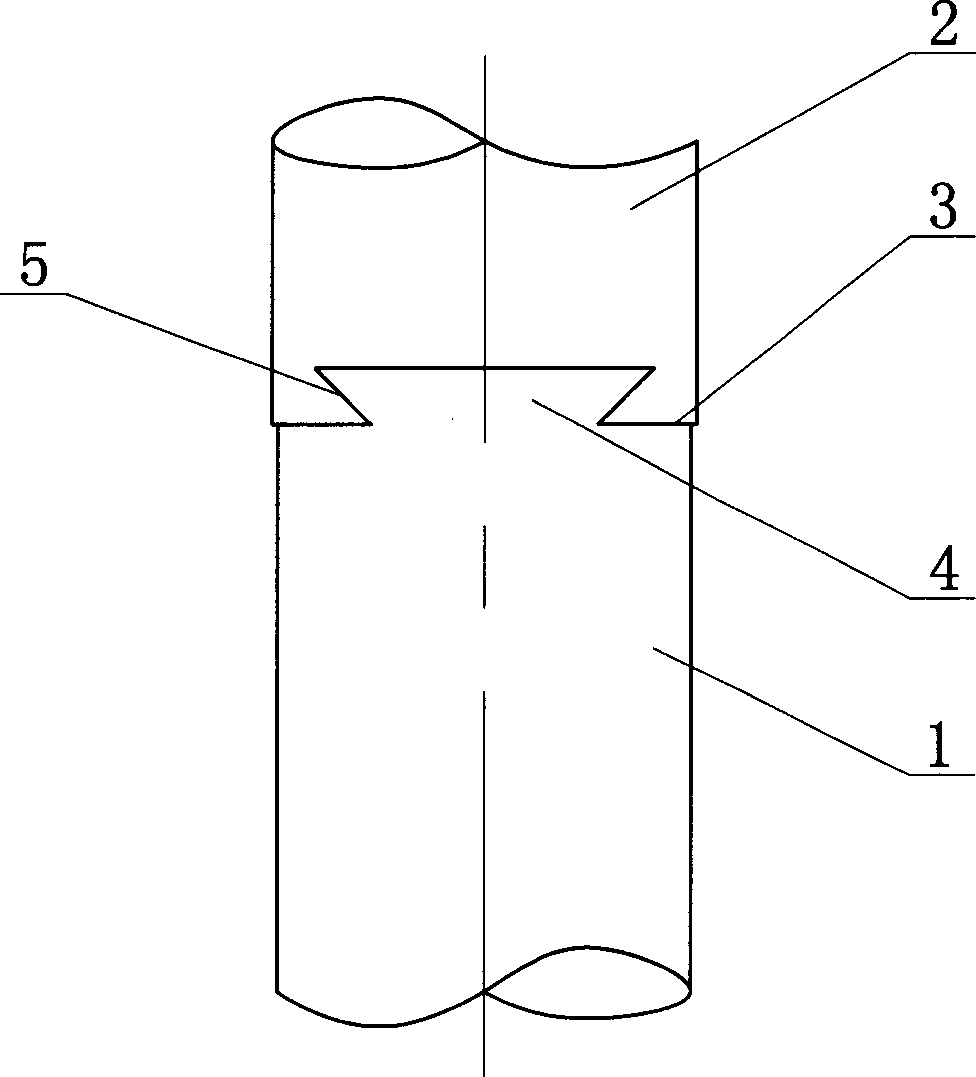

[0010] exist figure 2 In the illustrated embodiment of the present invention, the thin-walled drill bit includes a drill base body 1 and a drill collar 2 fixedly connected thereto, and the drill collar 2 includes a working part made of superabrasives and bonding agent and welded The welding layer made of material or the working part and the welding layer are all made of superhard abrasive and bonding agent; the joint surface 3 of the drill base 1 and the drill ring 2 is respectively provided with a notch 5 and a convex Card 4; in this embodiment, the notch 5 is provided on the drill ring 2, the convex card 4 is provided on the drill base 1, the notch 5 is provided along the axial direction, and the protruding card 4 is correspondingly arranged along the axial direction; The seam 5 is a trapezoid with a large bottom and a small opening at the upper end, and the corresponding convex card 4 is a trapezoid with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap