Process for fabricating semiconductor laser device

A technology of laser device and manufacturing method, which is applied in the direction of semiconductor laser device, semiconductor laser, structural details of semiconductor laser, etc., and can solve problems such as inability to reduce the interval of light-emitting points, inability to paste, large current resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

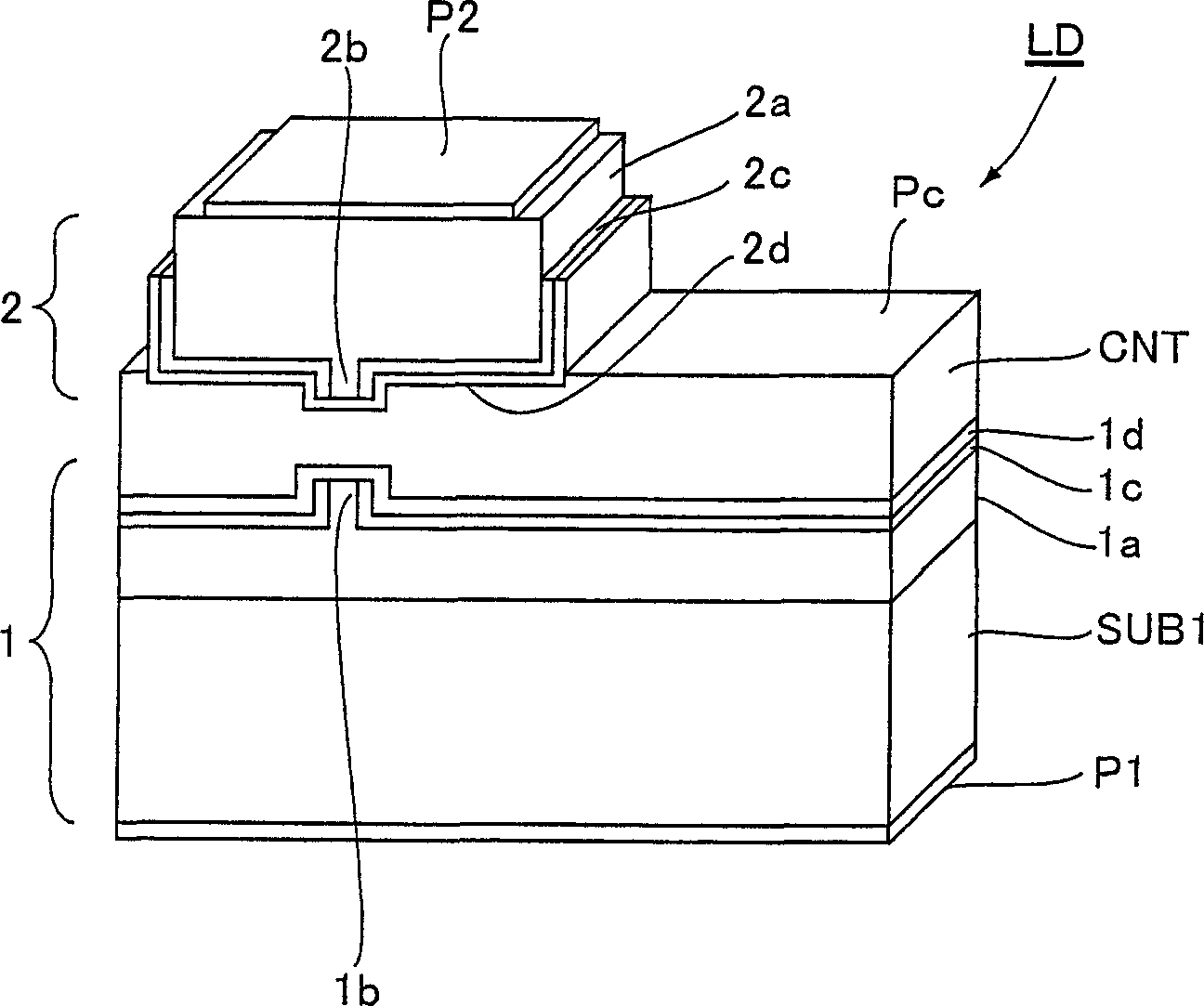

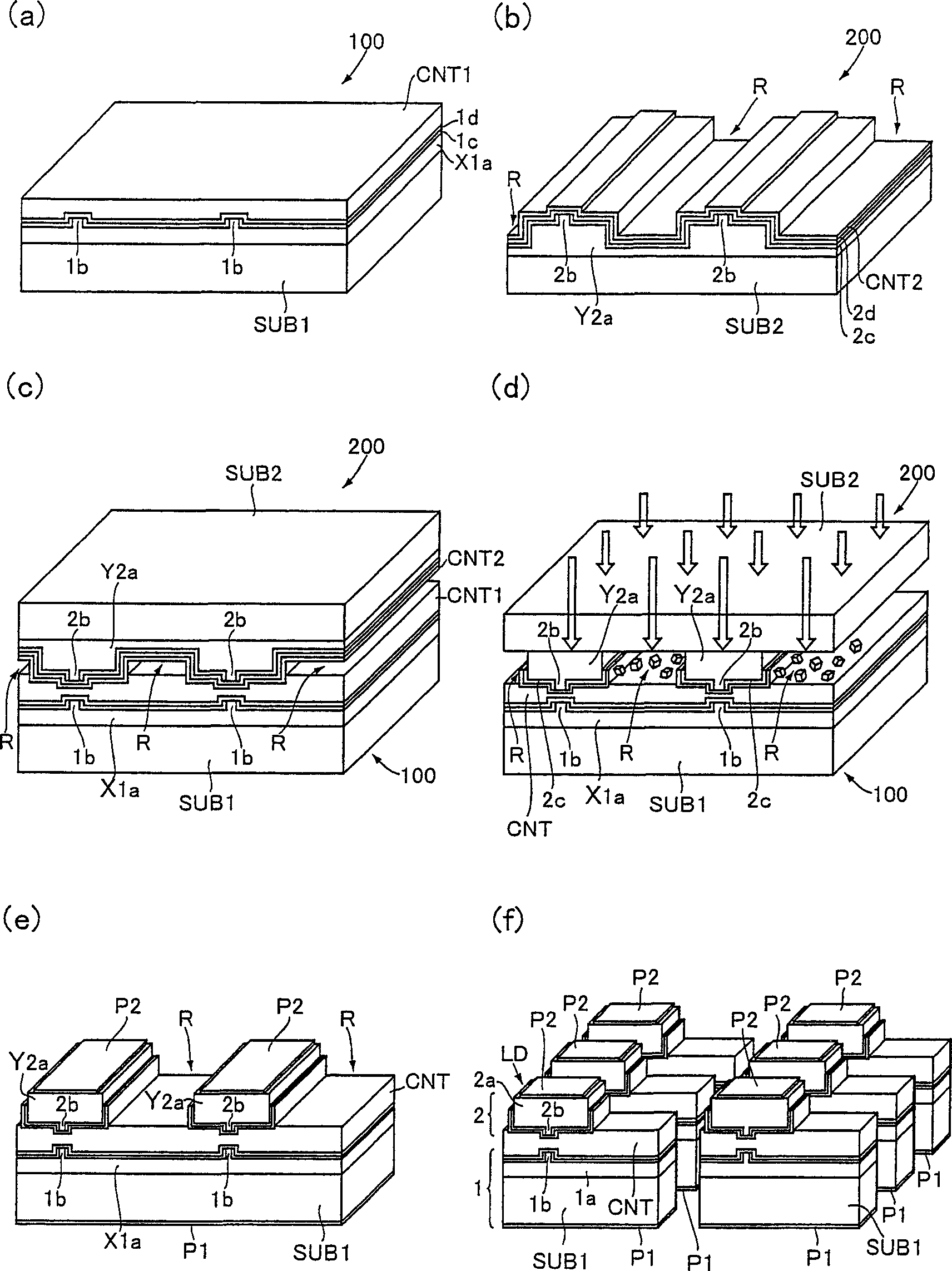

[0044] refer to figure 1 and figure 2 The first embodiment will be described. figure 1 is a perspective view showing an external structure of a semiconductor laser device manufactured by the manufacturing method of this embodiment, figure 2 It is a schematic diagram showing the manufacturing method of the semiconductor laser device of this embodiment.

[0045] exist figure 1 Among them, the semiconductor laser device LD manufactured according to this embodiment has a first light emitting element 1 and a second light emitting element 2 that emit laser light with different wavelengths, and the first and second light emitting elements are bonded by welding or the like of an adhesive layer CNT made of metal. The light emitting elements 1 and 2 are fixed and bonded as one.

[0046] The first light-emitting element 1 has: a semiconductor substrate SUB1 composed of a III-V compound semiconductor (for example, GaAs); on the semiconductor substrate SUB1, a first multilayer compos...

no. 2 Embodiment approach

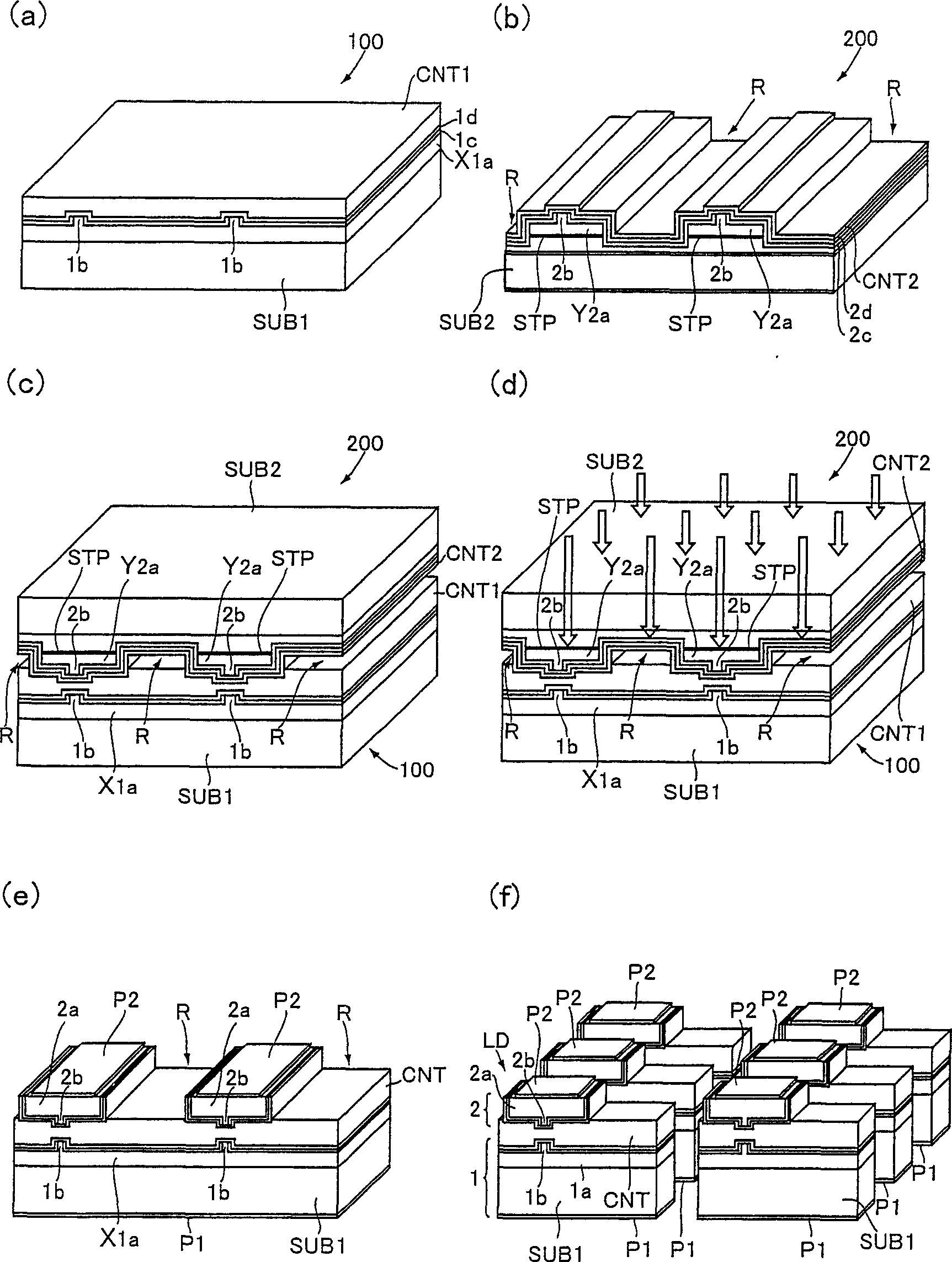

[0073] Below, refer to image 3 The second embodiment will be described. image 3 is a schematic diagram showing the manufacturing method of this embodiment, and the same symbols are used to denote and figure 2 same or equivalent parts.

[0074] The semiconductor laser device manufactured according to this embodiment basically has and figure 1 The semiconductor laser device shown has the same structure. However, as described below, the manufacturing method is different.

[0075] That is, to describe this production method, firstly, a image 3 The first intermediate product 100 and the second intermediate product 200 shown in (a) and (b). here, image 3 The 1st intermediate product 100 shown in (a) is made with figure 2 The intermediate product 100 shown in (a) has the same structure.

[0076] about image 3 The second intermediate product 200 shown in (b), and figure 2 The intermediate product 200 shown in (b) is different in that between the support substrate SUB...

Embodiment 1

[0090] Below, refer to Figure 4 ~ Figure 7 A specific example of the first embodiment will be described. Figure 4 A schematic cross-sectional view showing the structure of a semiconductor laser fabricated according to this embodiment, Figure 5 ~ Figure 7 A schematic diagram showing a method of manufacturing the semiconductor laser device of this embodiment. and, in Figure 4 ~ Figure 7 , use the same symbols to denote and figure 1 and figure 2 same or equivalent parts.

[0091] exist Figure 4 Among them, the semiconductor laser device LD manufactured according to this embodiment includes: a first light-emitting element 1 having a first laser resonator 1a formed on a semiconductor substrate SUB1; and a second light-emitting element 2 having a second laser resonator 2a, The first and second light emitting elements 1 and 2 are fixed and bonded integrally by an adhesive layer CNT made of a welded metal (for example, Sn).

[0092] The first laser resonator 1a has an n-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com