Multifunctional post-extraction tank for extracting biological reaction product

A technology of biological reaction and extraction tank, which is applied in chemical/physical/physicochemical fixed reactors, solvent extraction, mixers with rotating stirring devices, etc., can solve the problems of increasing investment and space, and achieve efficiency and increase Function, the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

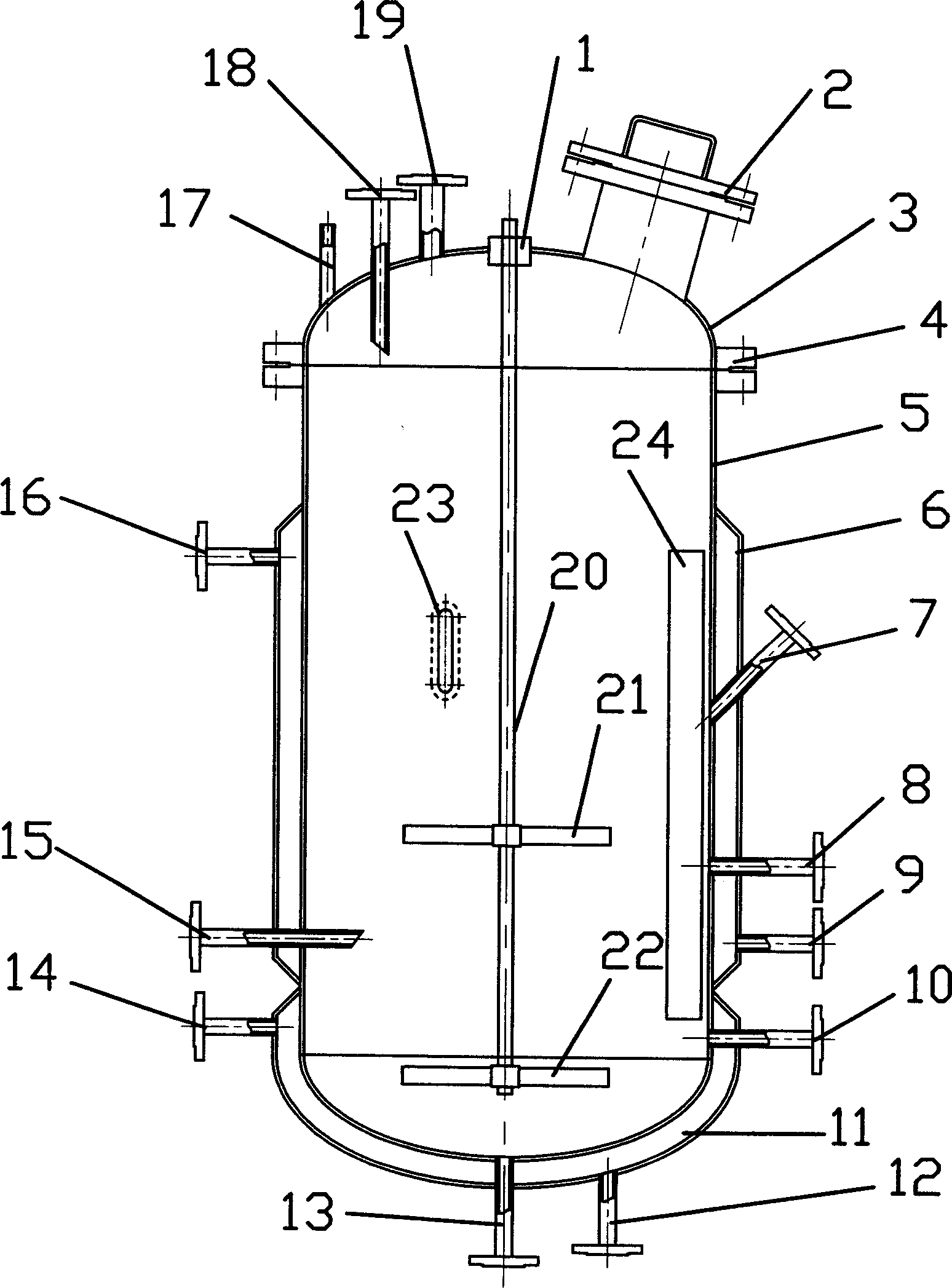

[0020] Embodiment 1: The structure of post-extraction tank

[0021] The tank body is composed of upper and lower heads (3) and a cylindrical cylinder (5). The lower head is welded to the cylinder, and the upper head and the cylinder are connected by the container flange (4); the stirring system is composed of a mechanical seal (1 ), a stirring shaft (20) and a stirring paddle (21 and / or 22). Different forms can be replaced, the number of layers and spacing of the stirring paddles can be adjusted; two or more layers of jackets (6 and 11) are arranged outside the tank body and tank bottom, and the cooling water, refrigerant or hot water inlet of the upper jacket or Steam condensate outlet (9), upper jacket cooling water, refrigerant or hot water outlet or steam inlet (16), lower jacket cooling water, refrigerant or hot water inlet or steam condensate outlet (12), lower clamp Set of cooling water, refrigerant or hot water outlet or steam inlet (14); the head of the tank is provi...

Embodiment 2

[0023] Application of multifunctional post-extraction tank in the process of post-extraction of biological reaction products

[0024] 1. Frozen crystallization: materials can be added from port 18, cooling water or refrigerant is connected to ports 9 and 12, cooling water or refrigerant is discharged from ports 14 and 16, and the mother liquor in the container is cooled through jackets 6 and 11. Select Appropriate rotation speed and stirring paddle can suspend the crystal particles in the solution, and the seed crystal can also be added from the interface 2. After properly controlling the amount of seed crystals and cooling speed, freezing and crystallization can be completed. After the crystallization is completed, after the necessary settling time, the supernatant mother liquor is drained from the interface 8 or 10, and the remaining crystal-rich mother liquor is centrifuged to obtain the crystal product.

[0025] 2. Evaporation and crystallization: materials can be added fr...

Embodiment 3

[0034] Example 3: Application of multifunctional post-extraction tanks in other processes

[0035] 1. Used as an enzyme reactor: the substrate can be added from the interface 18, the liquid enzyme can be added from the interface 18, and the solid enzyme can be added from the manual hole 2. The appropriate rotation speed and stirring paddle can be selected so that the enzyme reaction can be fully carried out. At the same time, the shear of the stirring paddle Do not destroy the enzyme by all means, and do not lose the enzyme activity. If it is necessary to adjust the temperature or pH value of the substrate, the temperature of the material can be adjusted by heating or cooling through the jackets 6 and 11, and the pH value of the material can be adjusted by adding acid or alkali through the interface 18. After the reaction, the material is discharged from the port 13 for further processing.

[0036] 2. Used as a liquefaction and saccharification tank for starchy raw materials:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com