Calcium phosphate cement

一种磷酸钙、磷酸二钙的技术,应用在磷酸钙矿物领域,能够解决限制使用、固化时间长、不容易注射等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

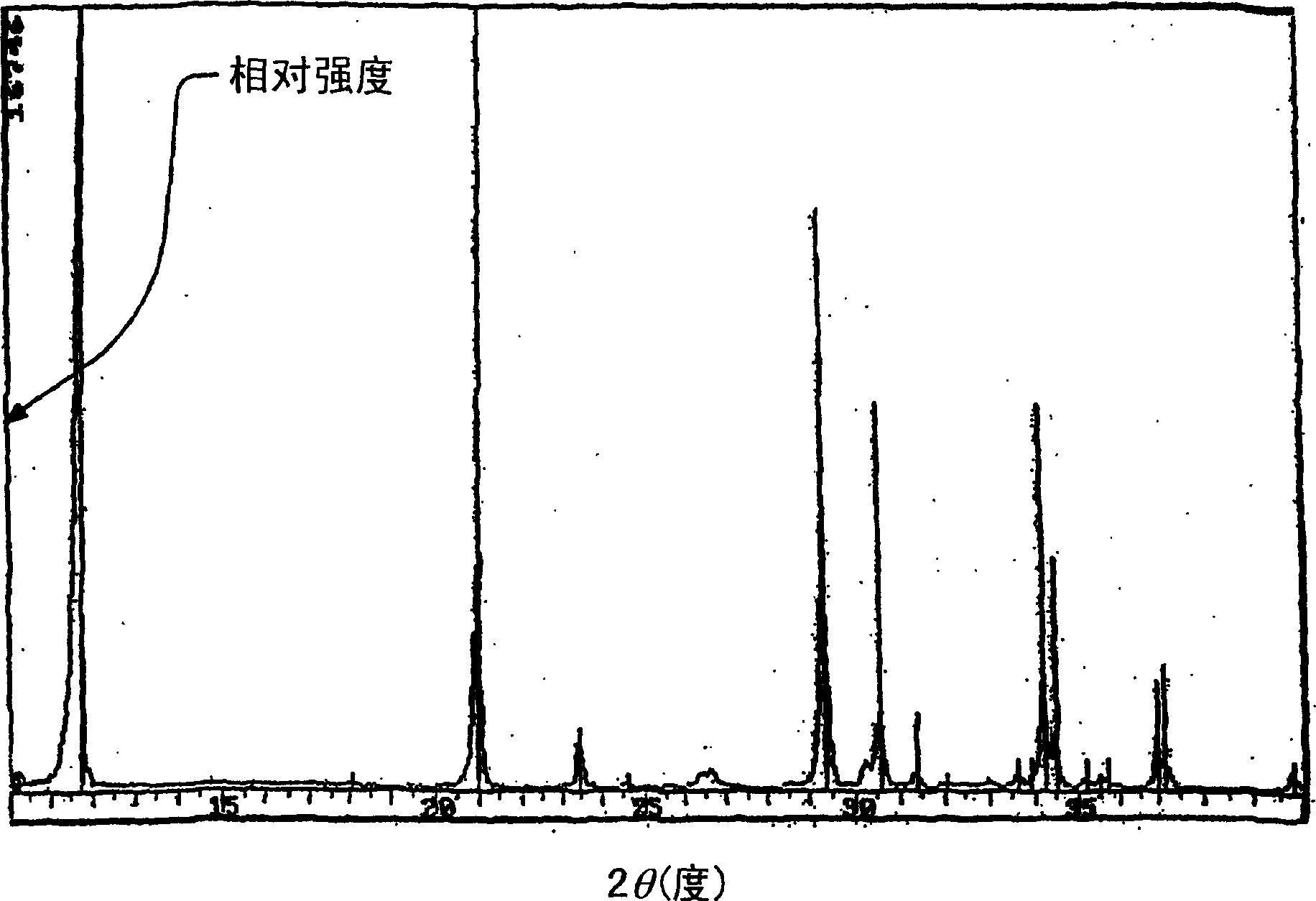

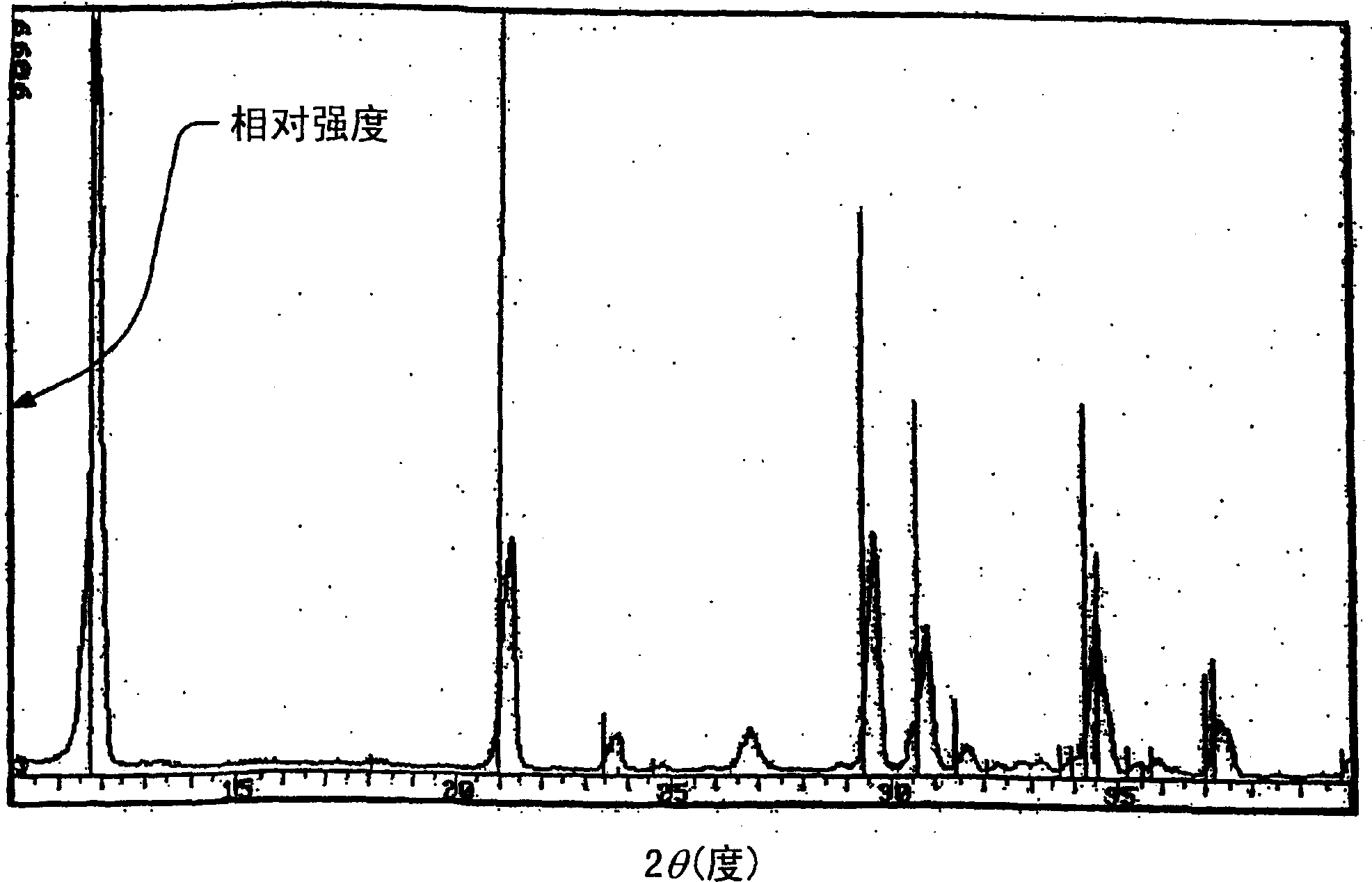

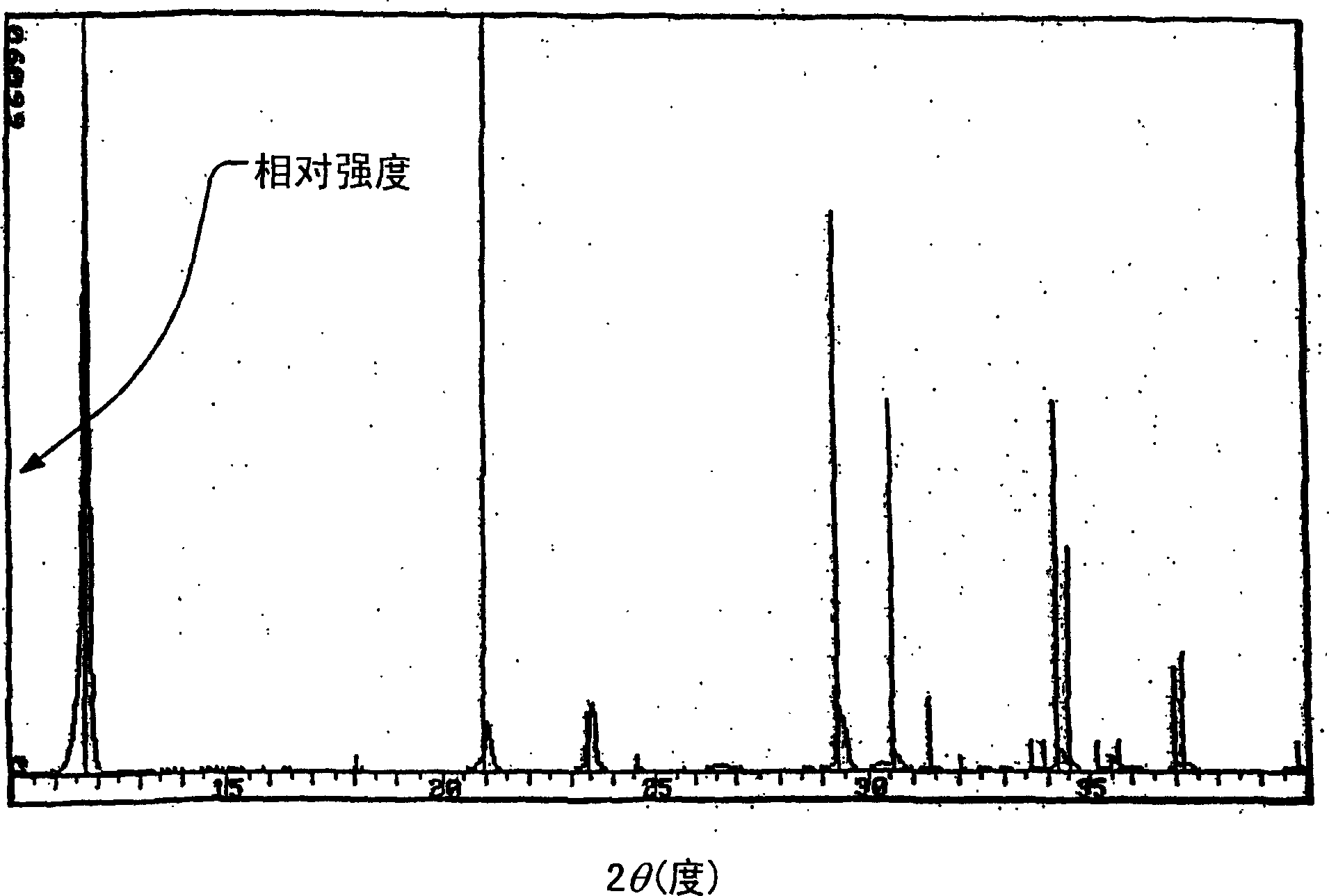

Image

Examples

Embodiment 1

[0092] Example 1: Preparation of DCPD containing 40 ppm magnesium.

[0093] (1) prepare the 30% phosphoric acid solution that adds 40ppm magnesium

[0094] In order to prepare the required 30% concentration of orthophosphoric acid (H 3 PO 4 ), in a 5 liter stainless steel beaker, 261 + / - 2 ml of 85% orthophosphoric acid was added to 737 + / - 2 ml of deionized water, and the beaker was placed on a hot plate set at 45°C. Then put a temperature measuring probe in the beaker to measure the temperature of the acid solution, turn on the hot plate, and heat the solution to 45°C. The solution was then stirred at 200 + / - 10 rpm, ensuring that the temperature probe measured the true temperature of the contents of the beaker. While heating the acid solution to 45°C, 0.0413 grams of magnesium oxide (MgO) (equivalent to about 40 ppm magnesium content or about 0.006883% by weight of DCPD), also referred to herein as the magnesium "spigot", was added to the solution. " solution or magnesi...

Embodiment 2

[0131] DCPD containing 60 ppm magnesium was prepared.

[0132] (1) prepare to add 30% phosphoric acid solution that has 60ppm magnesium

[0133] In order to prepare the required 30% concentration of orthophosphoric acid (H 3 PO 4 ), in a 5 liter stainless steel beaker, 261 + / - 2 ml of 85% orthophosphoric acid was added to 737 + / - 2 ml of deionized water, and the beaker was placed on a hot plate set at 47°C. Then put a temperature measuring probe in the beaker to measure the temperature of the acid solution, turn on the hot plate, and heat the solution to 47°C. The solution was then stirred at 200 + / - 10 rpm, ensuring that the temperature probe measured the true temperature of the contents of the beaker. While the acid solution was heated to 47°C, 0.0620 grams of magnesium oxide (MgO) (equivalent to about 60 ppm magnesium content or about 0.0085% by weight of DCPD) was added to the solution. Then, the pH probe and the temperature probe are calibrated and put into the acid s...

Embodiment 3

[0168] Preparation of tetracalcium phosphate (TTCP)

[0169] (1) Preparation of TTCP filter cake

[0170] To form a good TTCP, the TTCP slurry mixture needs to contain a solid to liquid ratio of 50% by weight solution, the solid component comprising 60.15% dicalcium phosphate anhydrous (DCPA) and 39.85% CaCO 3 , the liquid component comprising purified water. To prepare the TTCP "cake" for furnace sintering, ie 3500 grams of cake of TTCP, 2105.25 + / - 0.5 cake DCPA was accurately weighed into a 5 liter clean Buckner flask. Add 1394.75 + / - 0.5 grams of CaCO to this flask 3 . To this powder mixture was added 3.5 liters of deionized water. Table 7 lists the specific weights and percentages of these components.

[0171] Table 7

[0172] raw material

[0173] The Buckner flask was sealed with a suitable rubber stopper and nozzle attachment. The Buckner flask was placed in a Glen Creston Model T10-B turbulent mixer for 20 minutes for uniform mixing....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com