Transverse stress sensing system of photonic crystal fiber written with grating and implementing method thereof

A technology of photonic crystal optical fiber and optical fiber sensing system, which is applied in the direction of using optical devices to transmit sensing components, etc., can solve the problems of difficulty in lateral stress detection and failure to see photonic crystal optical fiber lateral stress sensing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

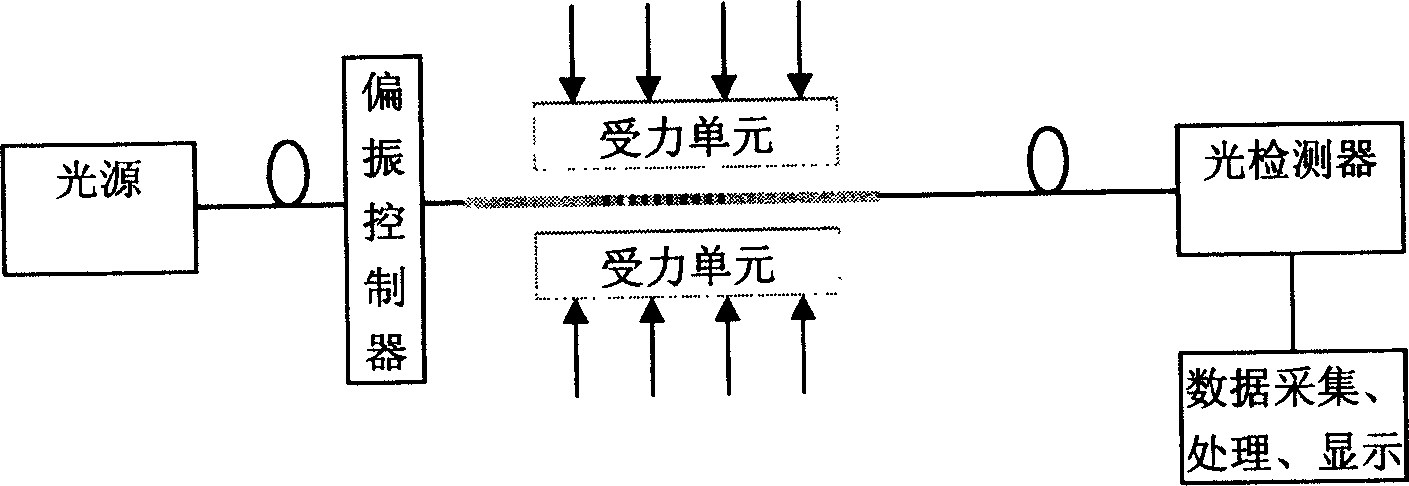

[0076] A long-period grating transverse stress (strain) sensing system is introduced into the photonic crystal fiber, a fiber sensing system for detecting transverse stress and strain, which mainly includes a laser light source, an ordinary single-mode fiber, a polarization controller, a zero-birefringence photonic crystal fiber or High birefringence photonic crystal fiber, long period fiber grating, force unit, photodetector, signal processing and display unit. The output light band of the laser light source should be able to cover the resonant wavelength of the long period grating.

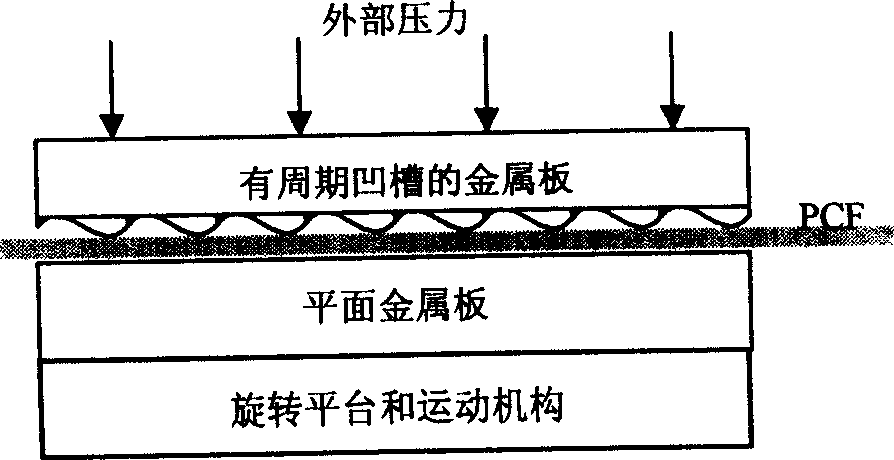

[0077] attached figure 1 As shown, the optical fiber in the figure is a photonic crystal fiber with zero birefringence or high birefringence. It is stressed in the pressure unit shown in Figure 4 and forms periodic microbends. 1 is the optical fiber, and 2 is the base of the pressure unit, which has periodic Groove, 3 is the upper cover of the pressure unit, 4 is the position of the optical fi...

Embodiment 2

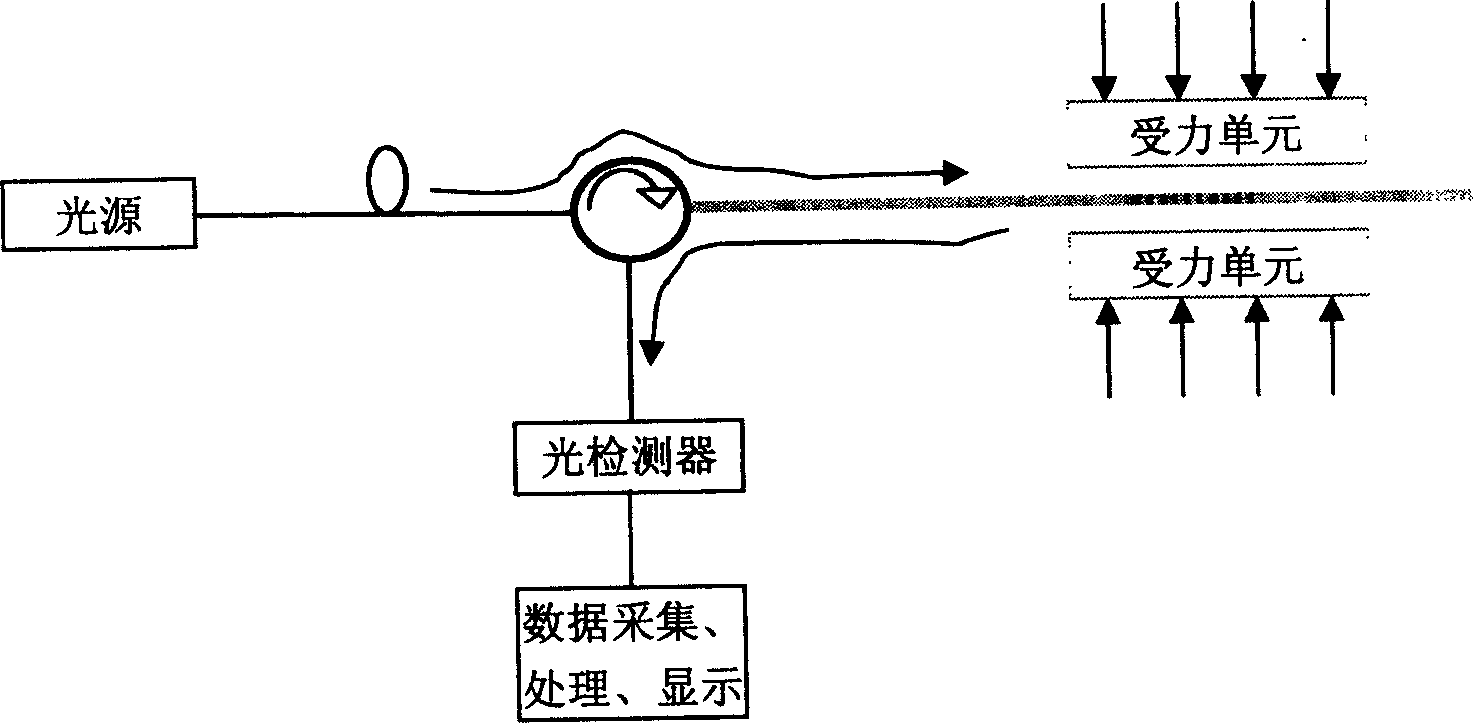

[0080] Transverse stress (strain) sensing system with Bragg grating written in photonic crystal fiber, a fiber sensing system for detecting transverse stress and strain, mainly includes laser light source, ordinary single-mode fiber, zero birefringence photonic crystal fiber or high birefringence Photonic crystal fiber, Bragg grating, force unit, optical circulator, light detector, signal processing and display unit. The output light band of the laser light source should be able to cover the resonant wavelength of the Bragg grating.

[0081] attached figure 2 As shown, the optical fiber in the figure is a zero-birefringence or high-birefringence photonic crystal fiber, in which Bragg gratings are written; the light is transmitted to the transverse stress detection area through a circulator and an ordinary single-mode fiber, and the light passes through the fiber under the action of transverse stress; The Bragg grating is reflected to the circulator, and output from one port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com