High-sensitivity MEMS photoelectric galvanometer, making and detecting method thereof

A micro-electronic machinery and galvanometer technology, applied in the measurement of current/voltage, measurement device, measurement of electrical variables, etc., can solve the problems of temperature drift, it is difficult to reach below the milliamp level, and the feedback current is small, so as to reduce the overall Size, good light transmission characteristics, effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

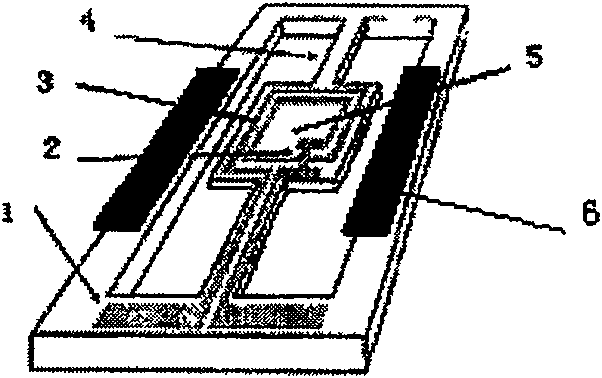

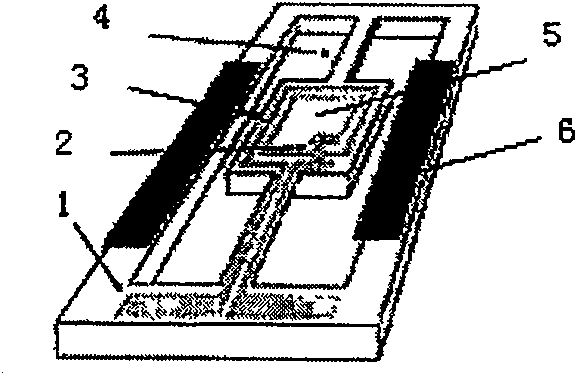

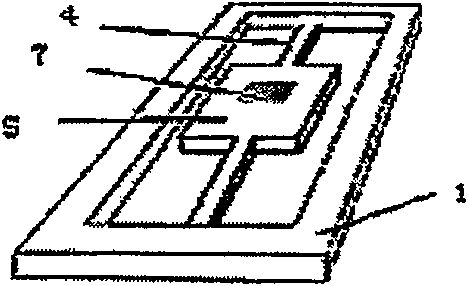

[0035] The lead wire inside the coil is made on the lower layer of the metal drive coil ( Figure 6 ), with a damping coil on the back ( Figure 4 ) device as an example to illustrate the implementation, wherein silicon dioxide is the insulating layer, silicon is the substrate, aluminum is used as the material of the MEMS drive coil and lead wires, the torsion plane, the metal coil, and the torsion beam are all rectangular, and the specific steps are as follows (for non-resistive Similar steps can be used for the structure of the nylon coil and the lead wire on the upper layer of the metal drive coil):

[0036] 1. Selection of device parameters

[0037] A. According to the initial value of the parameters of the rotation plane (length, width, height), the parameters of the lead wires and the parameters of the front metal drive coil and the back damping coil (number of turns, length, width, height, single-turn coil width, coil spacing) to calculate the entire Calculate the mom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com