Non-polarized composite gallium nitride base substrate and production method

A GaN-based, non-polarized technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of heat dissipation of high-power devices, easy breakdown of devices, and reduction of internal quantum efficiency of GaN-based devices. To achieve the effect of high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

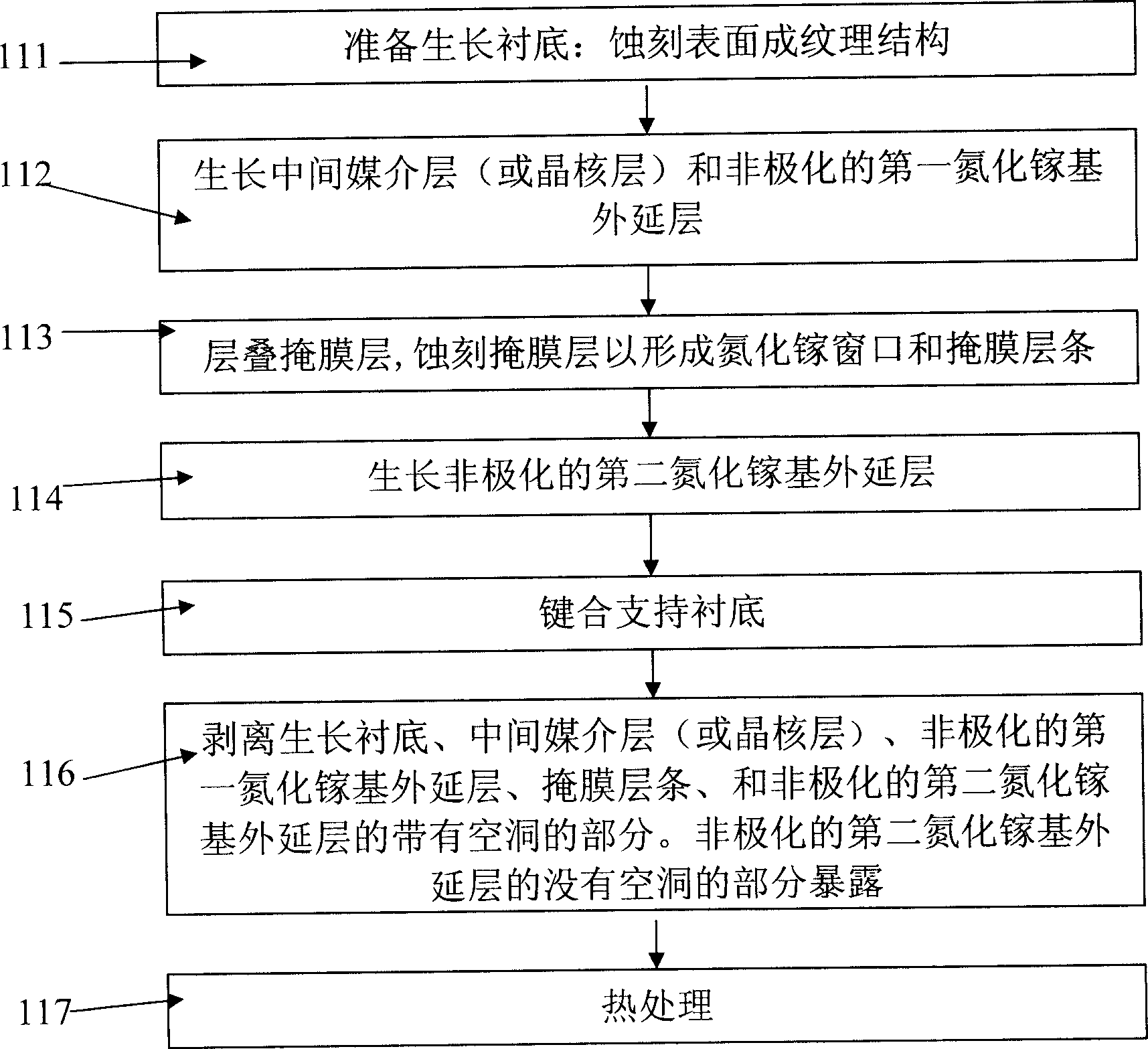

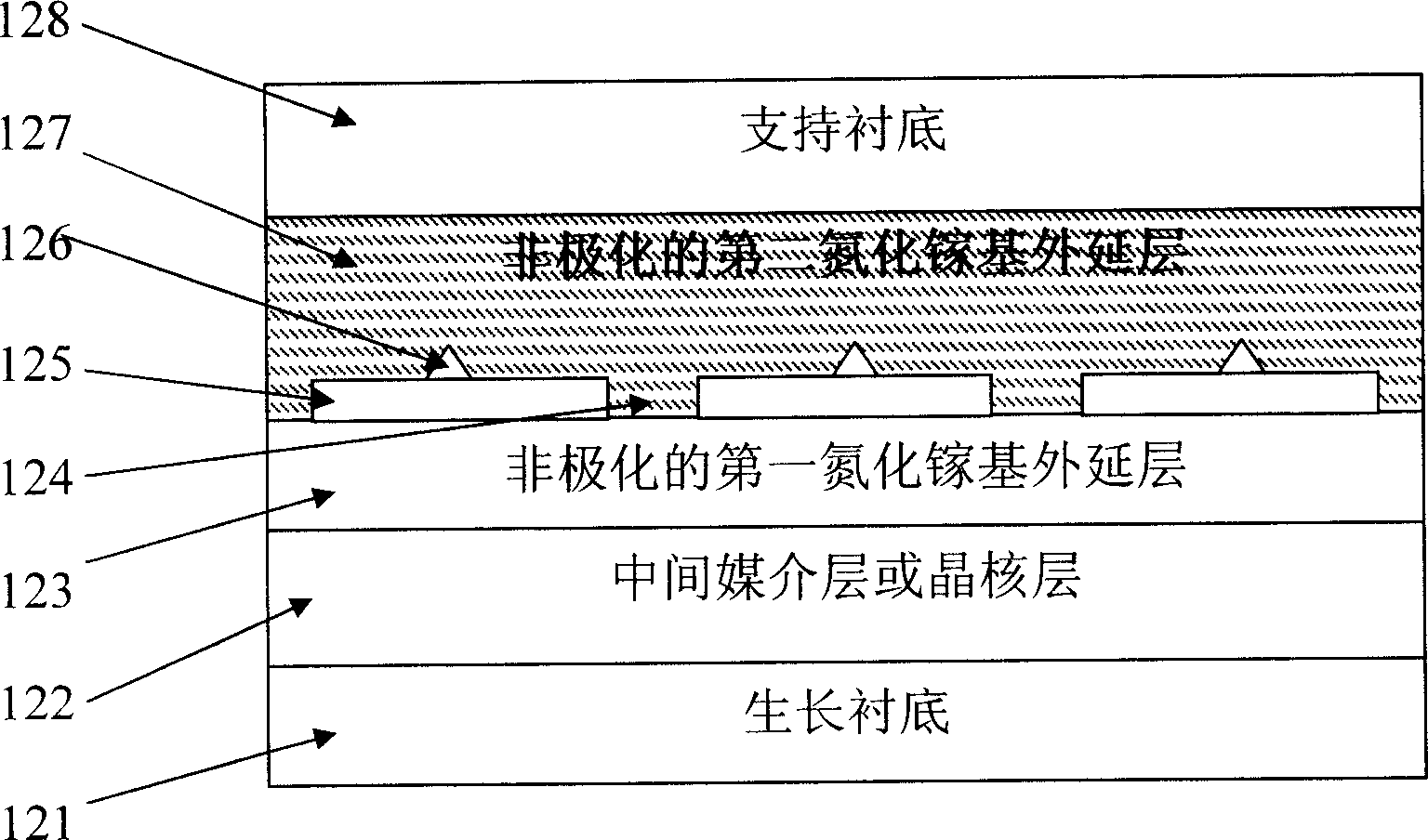

[0047] The first specific implementation example of the process flow step 112: using MOCVD, grow a layer of gallium nitride substrate with a thickness between 1 nm and 90 nm on the r-plane sapphire growth substrate (at a temperature of 400-900 ° C). Nucleation layer. The material of the crystal nucleus layer includes, but is not limited to, gallium nitride. An a-plane non-polarized first GaN-based epitaxial layer is grown on the crystal nucleus layer. A specific implementation example of growing a non-polarized a-plane first gallium nitride-based epitaxial layer: growing a non-polarized a-plane at a temperature above about 1000° C. and at a pressure less than 1 atmosphere, with an appropriate V / III ratio The thickness of the first GaN-based epitaxial layer is 1-5 microns.

[0048] A second specific implementation example of process flow step 112: using MBE, grow an aluminum nitride buffer layer on an m-plane 6H-silicon carbide growth substrate, and then grow an m-plane first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com