Method for manufacturing high precision antenna reflection surface without honeycomb interlayer

A technology of honeycomb interlayer and reflective surface, which is applied to antennas, electrical components, etc., can solve the problems of not being suitable for large-scale antennas and mass production, high weight and cost of reflective surface products, and complicated manufacturing process, so as to achieve excellent molding accuracy and improve The effect of performance-price ratio and simplification of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The best embodiment of the present invention is shown in Figure 1 and includes the following steps:

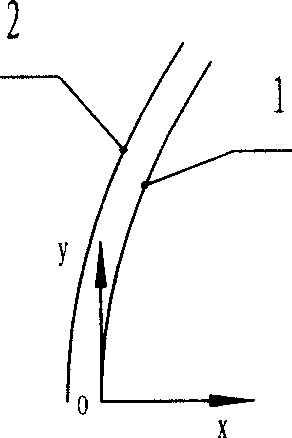

[0026] (1) In the XOY coordinate system, design the theoretical skin curve of the working reflective surface, and use the theoretical skin curve as the generatrix to rotate around the x-axis to form a theoretical skin surface 1, such as Picture 1-1 .

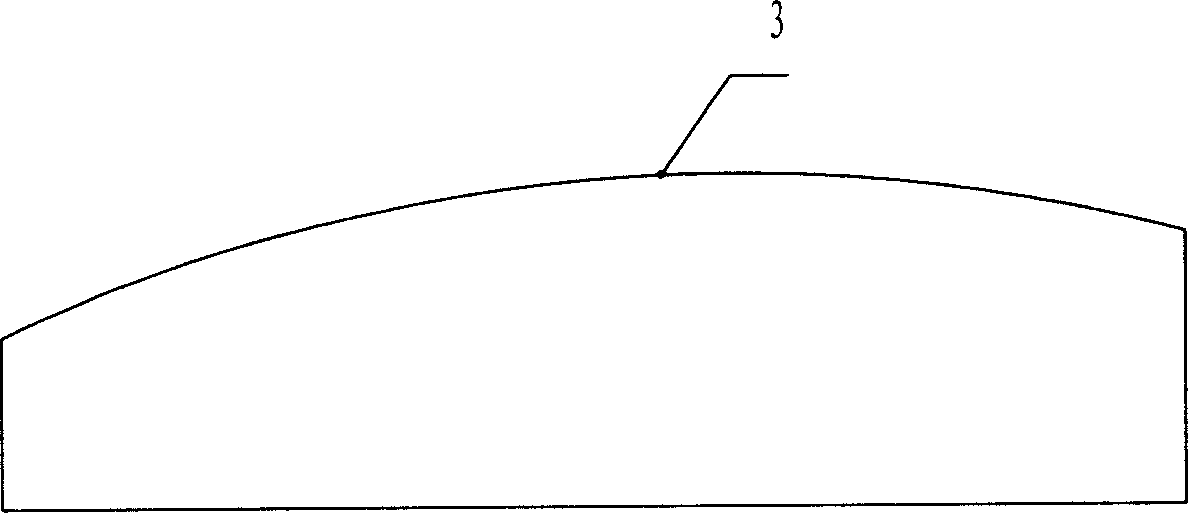

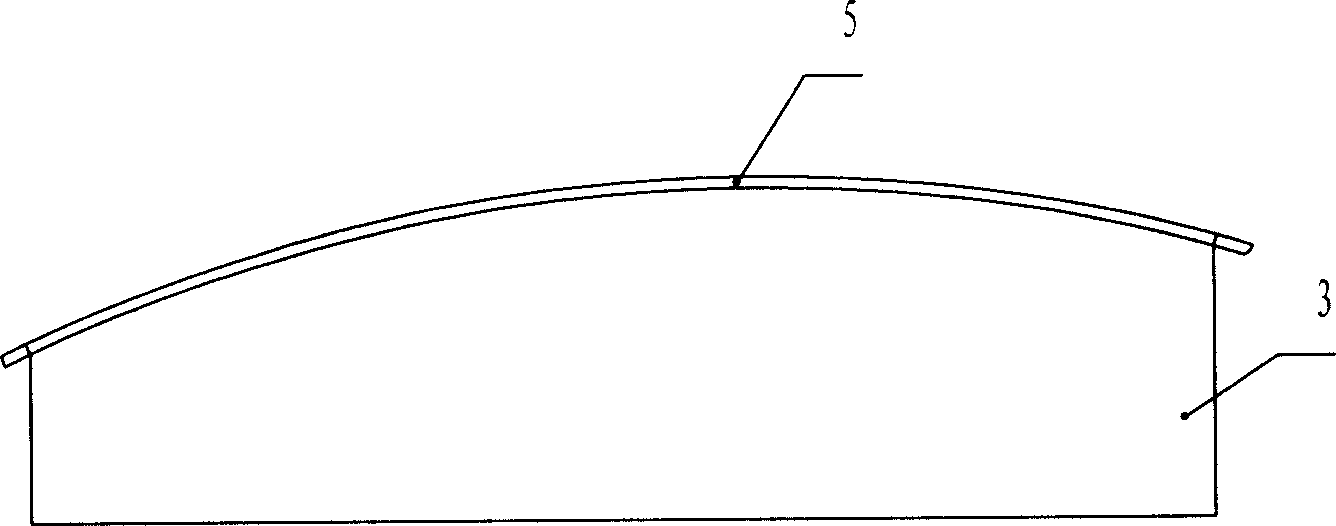

[0027] (2) According to the theoretical skin surface 1 design the skin surface drawing mold table 3 of the reflective surface unit. The reflective surface of large and medium-sized antennas is generally divided into a variety of smaller reflective surface units to adjust and assemble, and the same reflective surface unit adopts the same Manufacture of a drawing die set. The skin surface drawing mold table 3 adopts a cast iron material, and its surface is processed by a numerical control machine to form a high-precision skin surface, such as Figure 1-2 .

[0028] (3) Using anti-rust aluminum sheet or aluminum alloy sheet aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com