Prepn process of polynary positive pole material of lithium ion cell with compound transition metal oxide as intermediate product

A composite oxide, lithium-ion battery technology, used in oxide/hydroxide preparation, battery electrodes, electrical components, etc., to achieve excellent electrochemical performance, large size, and improve energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

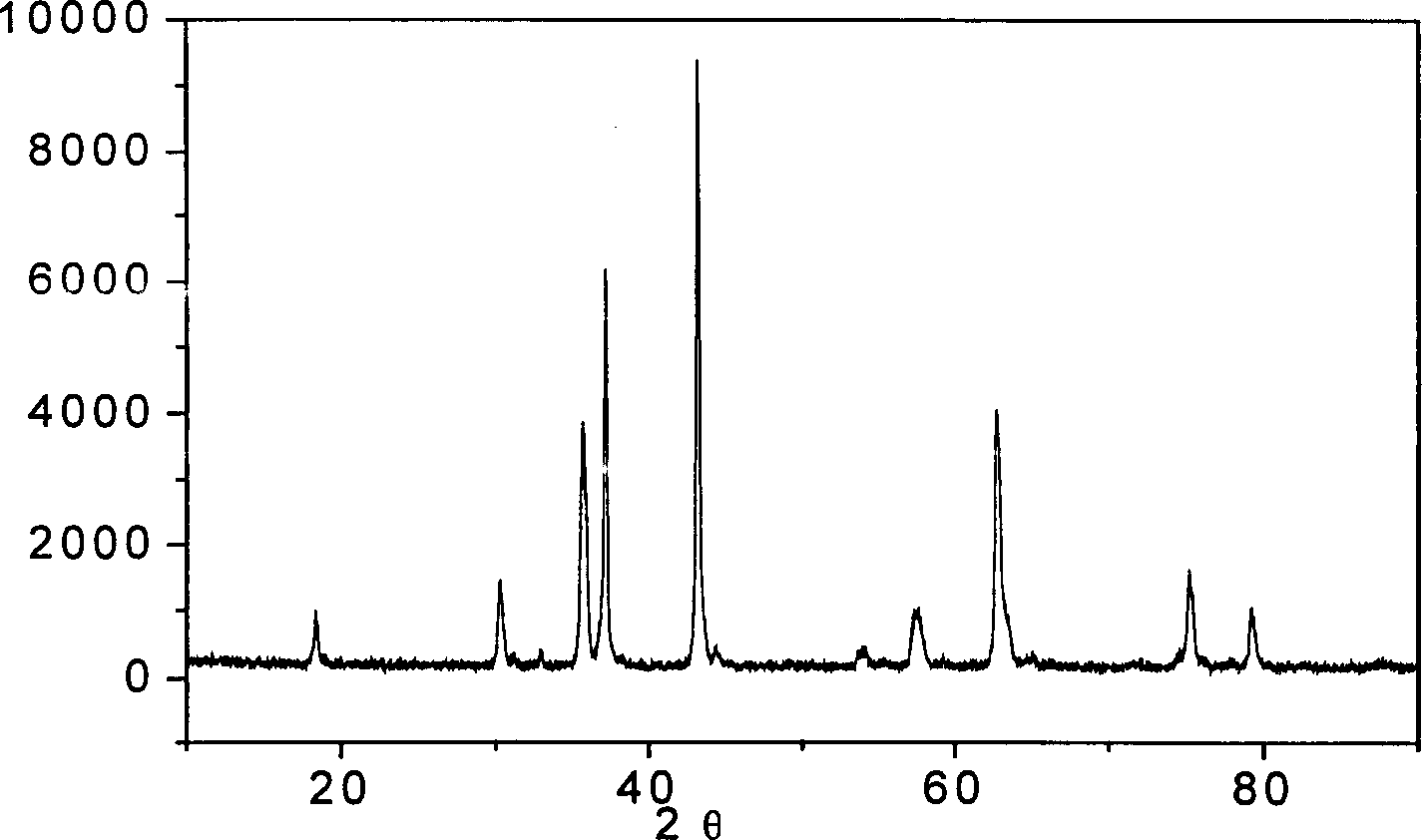

[0029] to synthesize LiNi 0.5 co 0.2 mn 0.3 o 2 As an example, measure and weigh the oxides of nickel, cobalt, and manganese (the molar ratio of Ni:Co:Mn=5:2:3), add water and wet mix for 1 hour, dry and dry mix for 3 hours after mixing, fully stir to make Mix evenly, transfer to a sintering furnace for the first step of calcination, the calcination temperature is 800°C, and the holding time is 6 hours, and the transition metal composite oxide intermediate product is obtained. figure 1 It can be seen from the XRD pattern that the intermediate product is a single-phase composite oxide with a spinel structure.

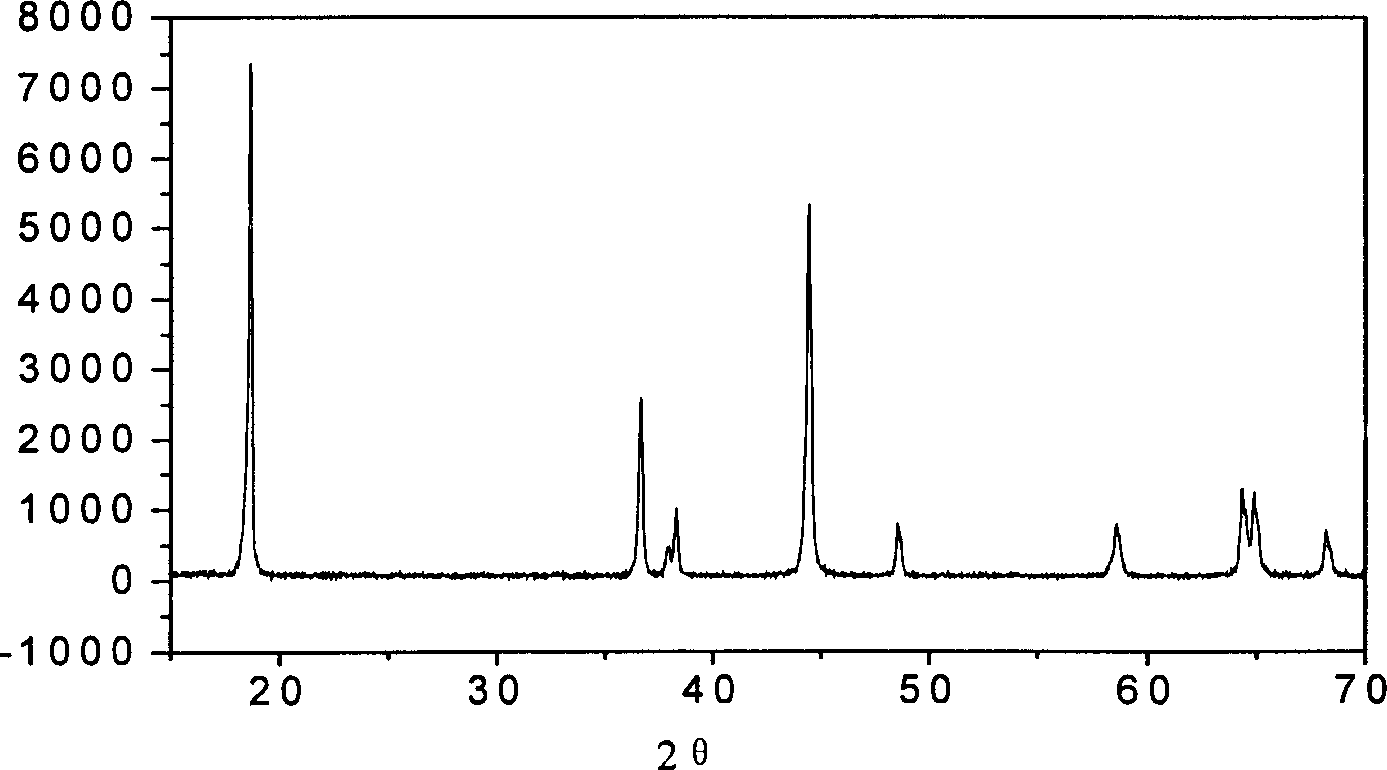

[0030] Add lithium hydroxide and lithium nitrate (the molar ratio of lithium hydroxide and lithium nitrate is 1:1) to the composite oxide intermediate product according to the metering, first wet mix and then dry mix (the method is the same as above), and carry out the second step of calcination after fully mixing , The calcination temperature in the air is 600°C, an...

Embodiment 2

[0037] Measure and weigh nickelous hydroxide, cobalt nitrate and manganese carbonate (the molar ratio of Ni: Co: Mn = 3: 3: 3), after mixing (the mixing method is the same as in Example 1) and calcining, the calcining temperature is 900 ° C, and the heat preservation After 4 hours, a transition metal composite oxide was obtained. Add lithium carbonate and lithium acetate (the molar ratio of lithium carbonate and lithium acetate is 2:1) to the composite oxide intermediate product according to the metering, after mixing (the mixing method is the same as that in Example 1), heat at 700° C. for 5 hours. After cooling and crushing, it is calcined at 950°C for 10 hours. After cooling, the final product LiNi can be obtained by ball milling 1 / 3 co 1 / 3 mn 1 / 3 o 2 . The discharge specific capacity of the material is 151mAh / g under the conditions of 0.5C and 2.8-4.3V / Li, and the capacity retention rate is 92% after 50 cycles.

Embodiment 3

[0039] Measure and weigh nickel nitrate, cobalt acetate and manganese dioxide (Ni: Co: Mn molar ratio = 7: 2: 1), wet mix with ethanol first, dry mix after drying, and then calcine at a temperature of 500°C , and the holding time was 15 hours to obtain a transition metal composite oxide. Add lithium carbonate, lithium hydroxide and lithium nitrate (the molar ratio of lithium carbonate, lithium hydroxide and lithium nitrate is 1:1:1) to the composite oxide intermediate product by metering, after mixing (the mixing method is the same as in Example 1), After 500 ℃, heat preservation for 15 hours. After cooling and crushing, it is calcined at 800°C for 30 hours. After cooling, the final product LiNi can be obtained by ball milling 0.7 co 0.2 mn 0.1 o 2 . The discharge specific capacity of the material under the condition of 0.5C and 2.8-4.3V / Li is 154mAh / g, and the capacity retention rate is 83% after 50 cycles.

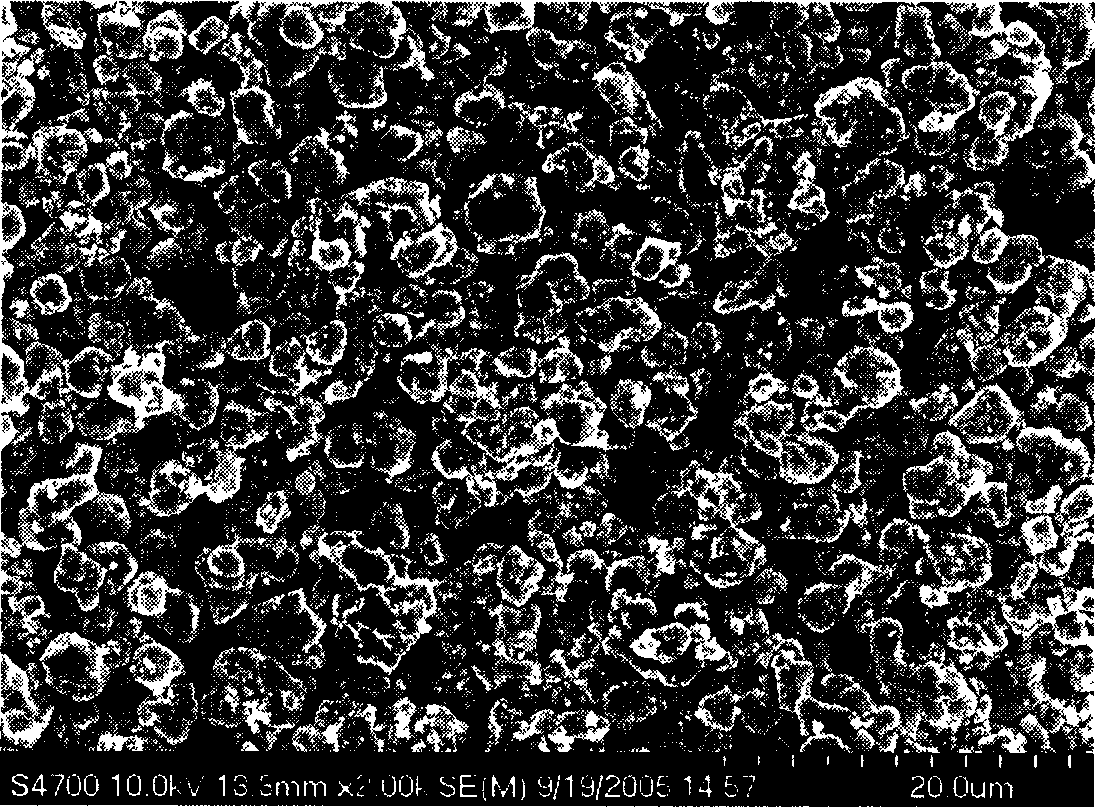

[0040] LiNi multi-element cathode material for lithium-ion b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com