Biuret compounds, their preparation and use and intermediates for their preparation

A compound, biuret technology, applied in the field of biuret compound and its preparation, use and intermediates in the preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

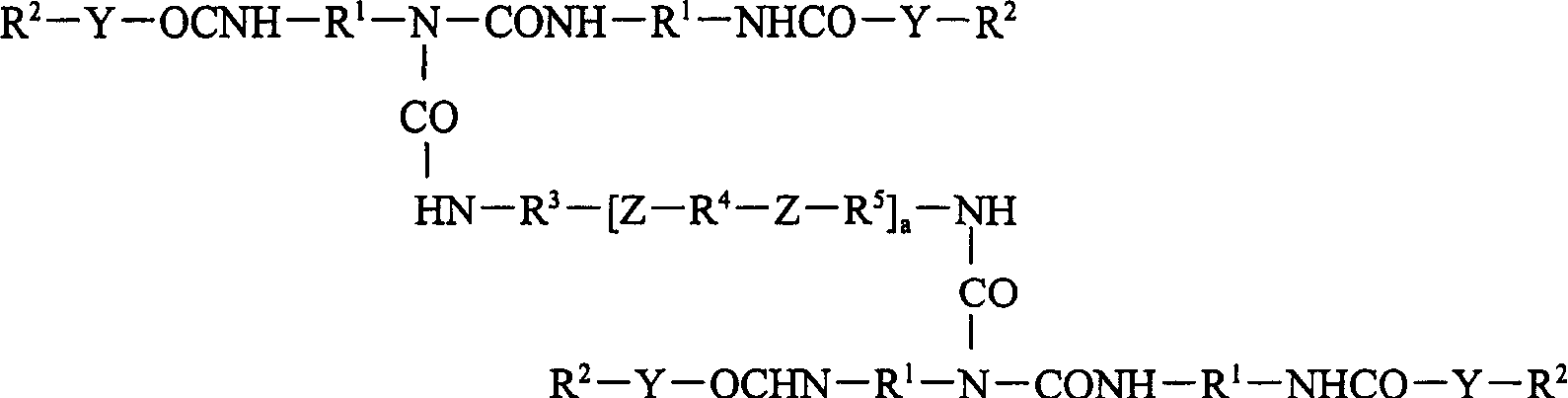

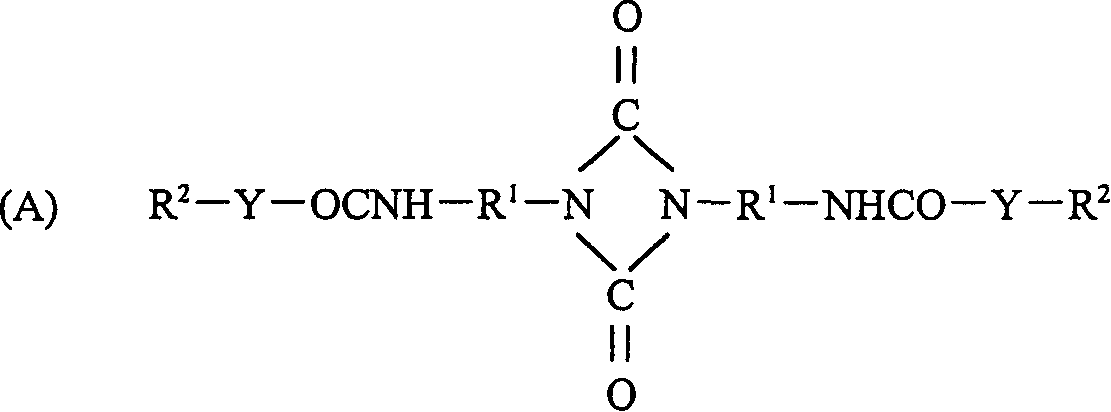

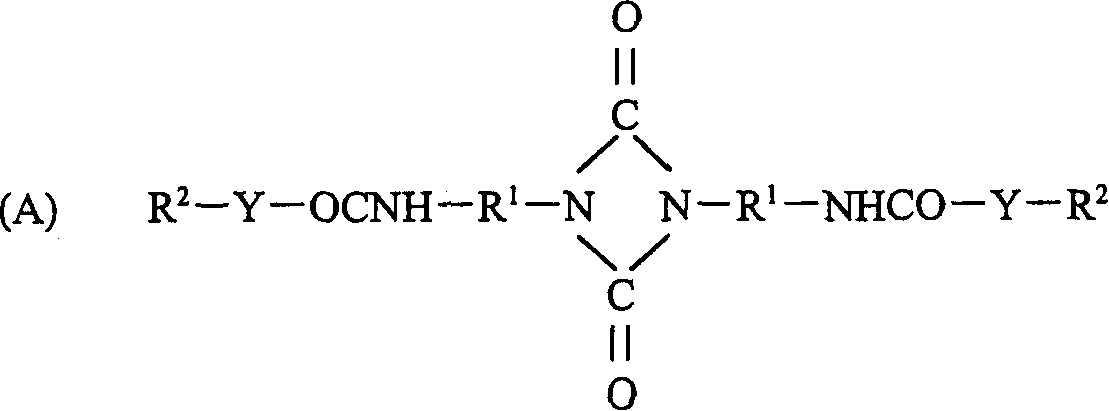

Method used

Image

Examples

Embodiment 1

[0053] At room temperature, 79.6 g (0.2 mol) of hexamethylene diisocyanate uretdione (Desmodur N3400 from Bayer) and 300 g (0.4 mol) methoxypolyethylene glycol 750, these initial charges were heated to 80°C. The reaction was allowed to proceed to such an extent that isocyanate was no longer detected. The reaction mixture was then cooled to 50 °C.

[0054] Preparation of component B of the present invention:

Embodiment 2

[0056] At room temperature, 168 g (0.3 mol) of dimer acid, 46.4 g (0.4 mol) of hexamethylenediamine, and 92 g of Shellsol were continuously charged to a 1-liter three-necked flask equipped with a stirrer, reflux condenser, and thermometer. A (high boiling aromatic hydrocarbon solvent, Shell), and these initial charges were heated slowly to 160°C. The water released slowly during the reaction was separated azeotropically by a water separator. When the acid value is less than 3, the reaction ends. The reaction mixture was subsequently cooled to 50°C.

[0057] The preparation of the biuret adduct of the present invention:

Embodiment 3

[0059]At room temperature, 103.6 g (0.1 mol) of the reaction product from Example 1 and 153.1 g (0.05 mol) of the reaction product from Example 2 were continuously charged to a 1-liter three-necked flask with a stirrer, a reflux condenser and a thermometer. reaction product, the mixture was heated to 80°C. The reaction mixture was stirred for an additional 3 hours until the amine number was less than 3. The product was then diluted to 50% solids with isobutanol.

[0060] Example

uretdione

Amine / Alcohol Component

4

Hexamethylene diisocyanate uretdione

5

Hexamethylene diisocyanate uretdione

6

Hexamethylene diisocyanate uretdione

Jeffamine M600

7

Hexamethylene diisocyanate uretdione

Methoxypolyethylene glycol M350

8

Hexamethylene diisocyanate uretdione

Methoxypolyethylene glycol M500

9

Hexamethylene diisocyanate uretdione

Jeffamine M2070 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com