Method for preparing alpha-olefine acid by olefin oxidation

A technology of alkenoic acid and olefin, which is applied in the direction of organic chemical methods, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of difficult catalyst preparation, high production cost, and high reaction temperature, and achieve high conversion rate and selectivity. The effect of less reaction by-products and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

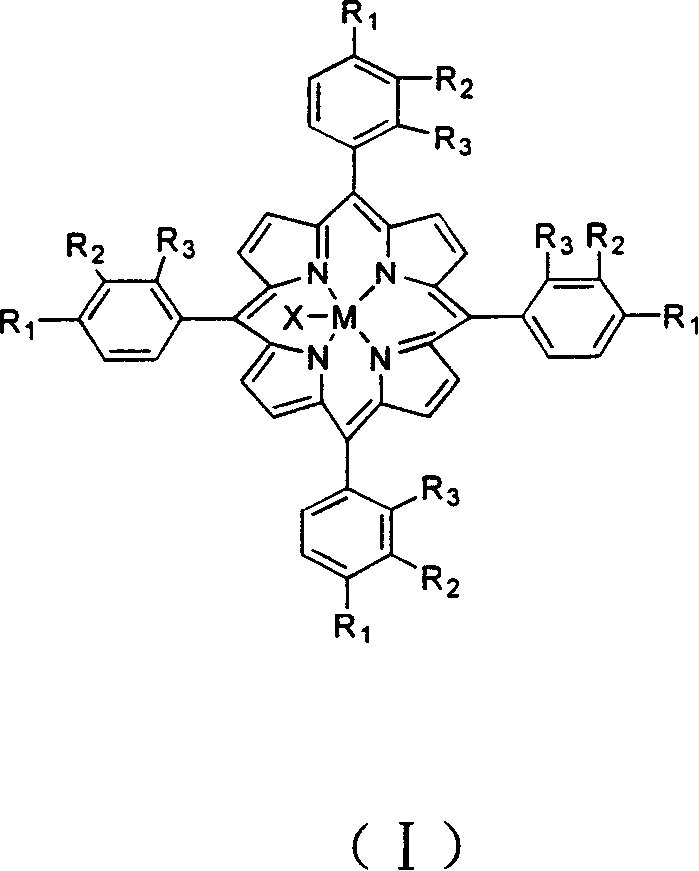

[0014] In the fixed-bed column-and-tube reactor, load solid-carrying 5ppm structure formula (I) metal porphyrin molecular sieve catalyst, in the formula R 1 = H, R 2 =R 3 =CH 3 , M=Mn, the reaction gas containing propylene 10% air is passed through the bottom of the tubular reactor, the reaction pressure is 1 atm, the reaction temperature is 180 ° C, the control of propylene and air flow rate makes the residence time less than 1 minute. The oxidized liquid from the tubular reactor is cooled and separated to obtain acrylic acid. The conversion rate of propylene is 100%, and the selectivity of acrylic acid is 95%.

Embodiment 2

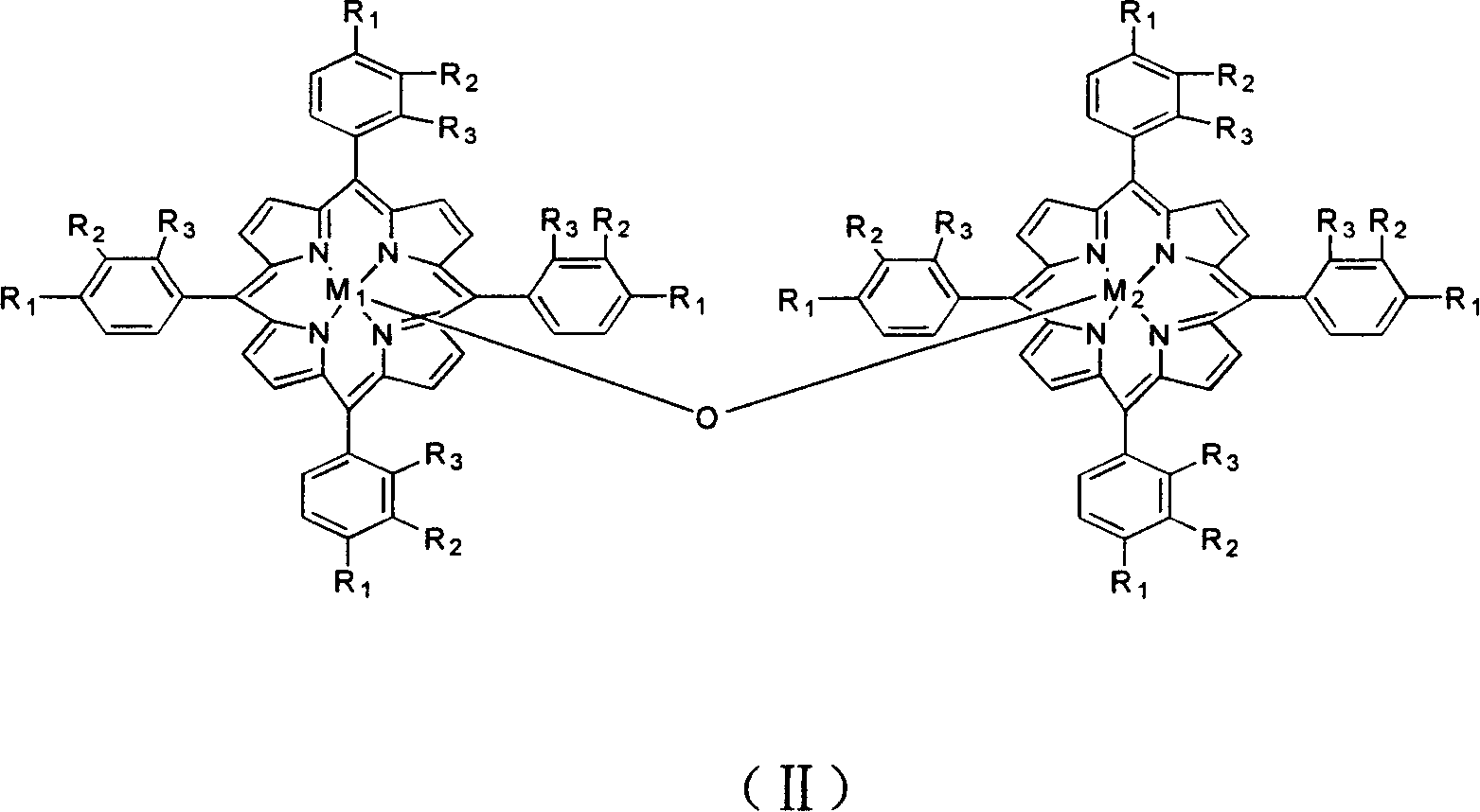

[0016] Implementation process is the same as embodiment 1. Catalyst is the metalloporphyrin of silica gel immobilization 20ppm structural formula (II), wherein R 1 =R 2 =OH, R 3 =Cl,M 1 = M 2 = Fe. Reaction gas composition: isobutene 15%, air 40%, nitrogen 45%. The reaction pressure is 1.5 atm, the reaction temperature is 150° C., the conversion rate of isobutene is 100%, and the selectivity of 2-methacrylic acid is 87%.

Embodiment 3

[0018] Implementation process is the same as embodiment 2. Catalyst is the metalloporphyrin of diatomite immobilized 30ppm structural formula (I), R 1 =OCH 3 , R 2 =R 3 =OH, M=Co. Reaction gas composition: 20% of 2-butene, 22% of oxygen, and 58% of nitrogen. The reaction pressure is 3 atm, the reaction temperature is 160°C, the conversion rate of 2-butene is 95%, and the selectivity of 2-butenoic acid is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com