Photoetching machine synchronous sequential control serial data communication method and system and use

A technology of serial data and synchronous timing, which is applied in the field of lithography to achieve the effect of realizing precise synchronous control, realizing reliability, and improving real-time and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment, the present invention is explained in more detail:

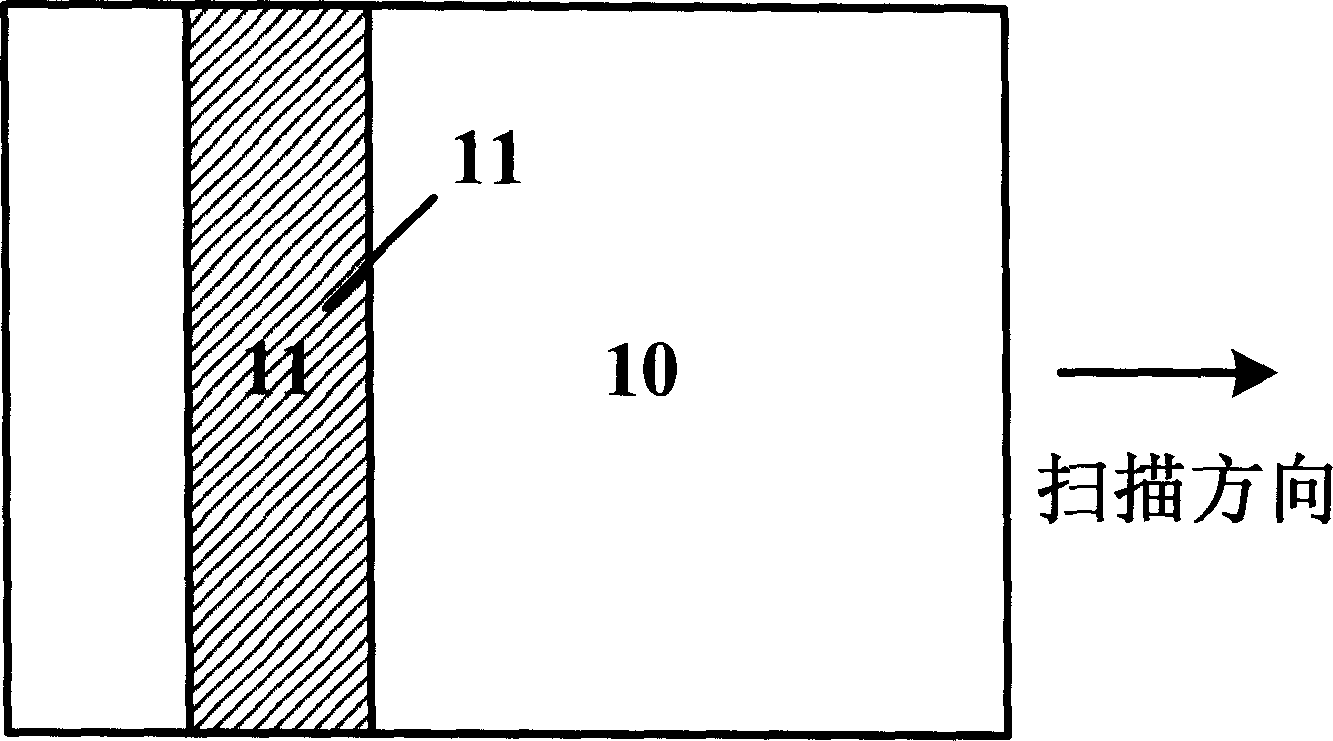

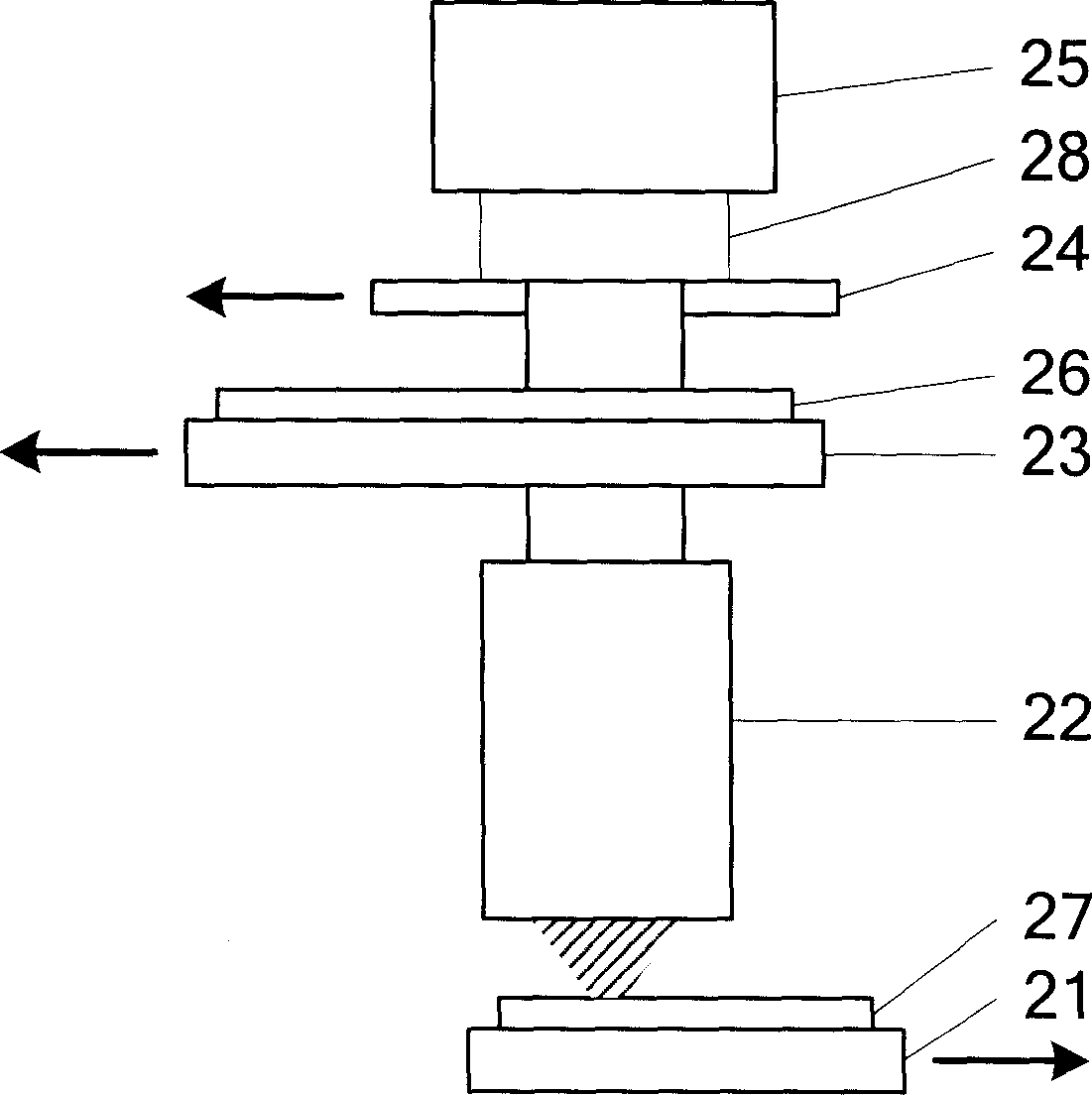

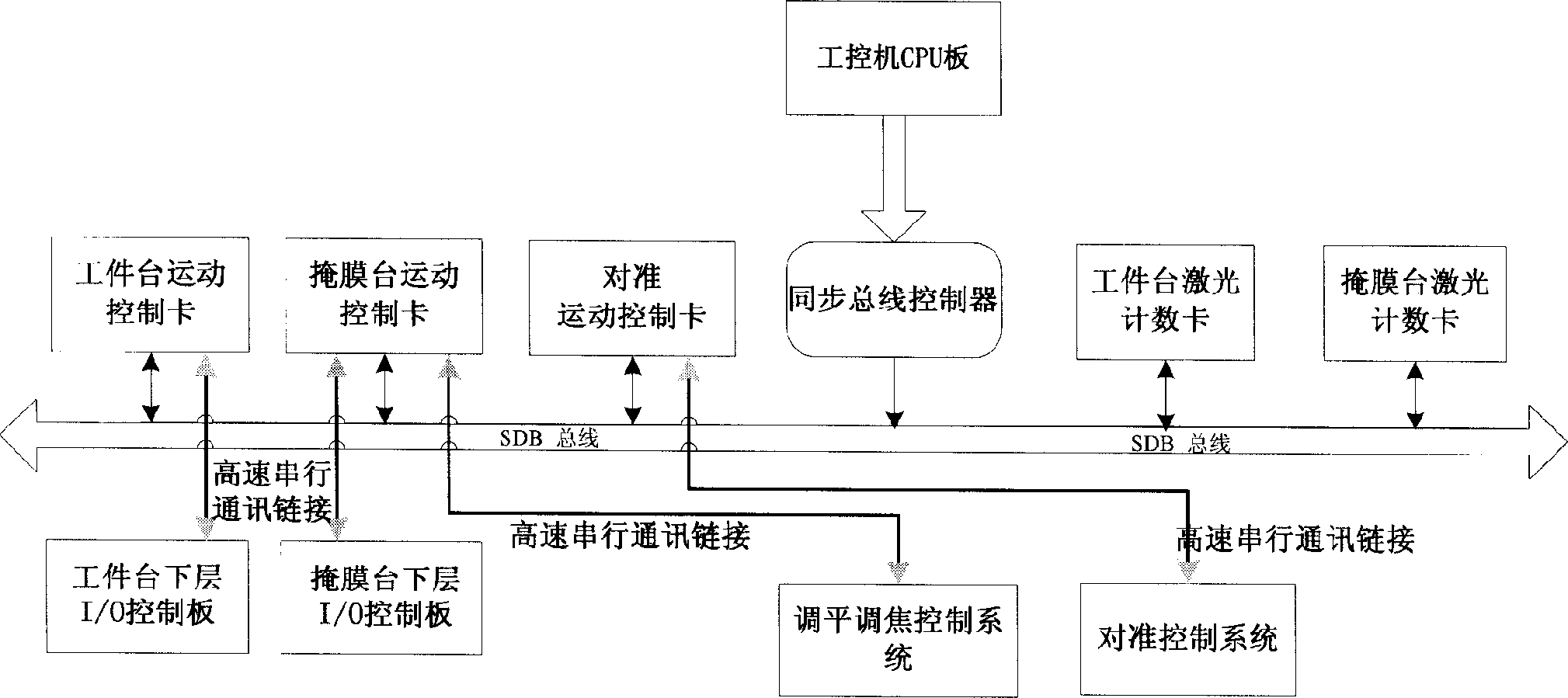

[0030] The invention is a high-speed serial data communication mechanism for synchronous timing control of a step-scan projection lithography machine, and realizes direct synchronous signal control of multiple control units for exposure scanning of a step-scan projection lithography machine. This process takes the synchronous bus data transmission cycle as a strict time control benchmark, and strictly controls the trigger time points of each synchronous signal, so as to realize the real-time and synchronization of data and signals between various control units.

[0031] The step-scan projection lithography machine is a very complex control system, which has multiple control units and synchronization requirements for various data communications. In order to achieve strict synchronization control between each control unit, a step-scan projection is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com