Method for making complicate three dimension microstructure or micro device at low cost

A micro-device, low-cost technology, applied in the manufacture of micro-structure devices, micro-structure technology, micro-structure devices, etc. Problems such as the realization and popularization of complex MEMS, the design of MEMS and functional realization obstacles, etc., to achieve the effect of not being constrained by complex geometric shapes, high aspect ratio, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

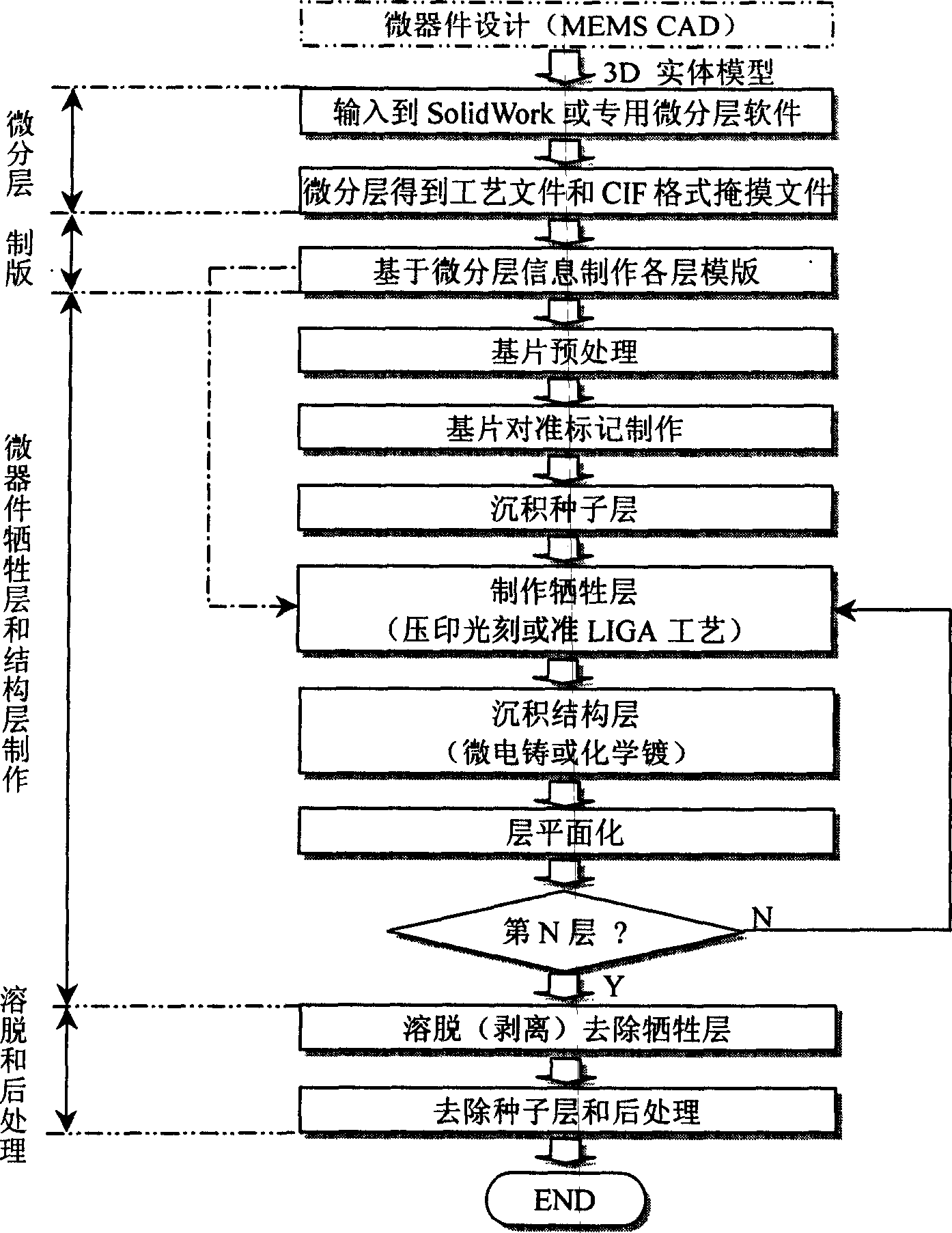

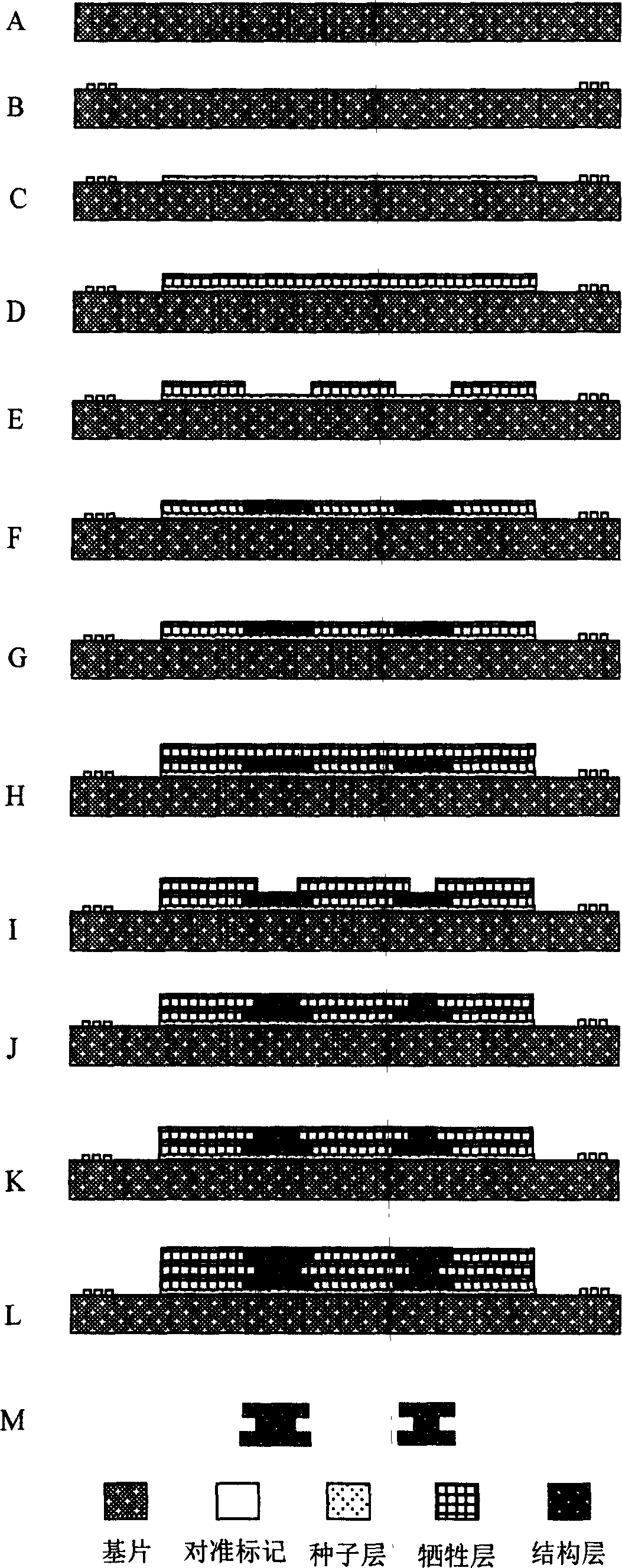

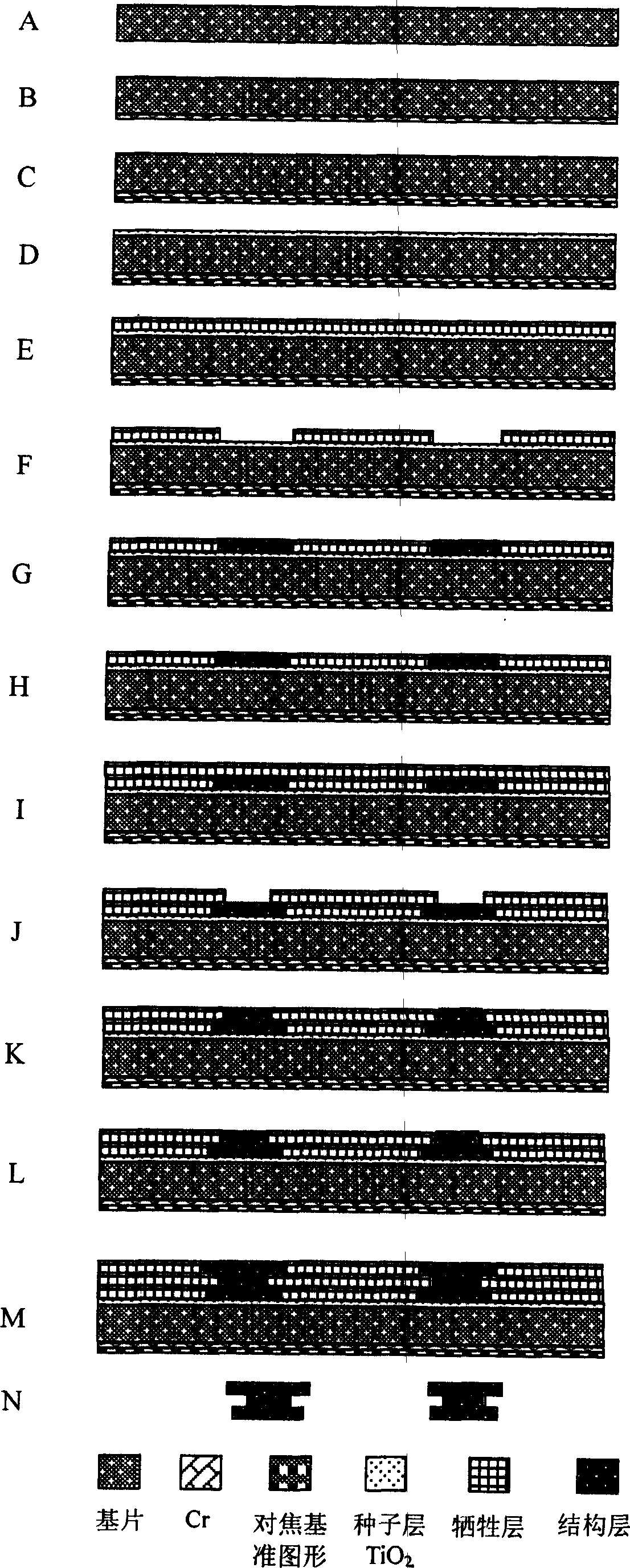

[0041] 1) Technical approaches for the fabrication of complex 3D micro-devices

[0042] see figure 1 , the technical approach of utilizing the present invention to make complex three-dimensional micro-device is: 1. micro-layering of micro-device three-dimensional CAD solid model; 2. template making;

[0043] (1) Microlayering of 3D CAD solid model

[0044] Use software such as SolidWorks (or special software) to decompose according to the three-dimensional geometric structure characteristics of the micro-device according to the processing layer, discretize the three-dimensional CAD solid model of the micro-device along the Z direction, and divide it into two-dimensional thin layers with a certain thickness, and obtain each layer The geometric data information of the cross-section generates process data and CIF format mask files, and completes the conversion from three-dimensional entities to two-dimensional template data (MEMS process planning software can be used).

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com