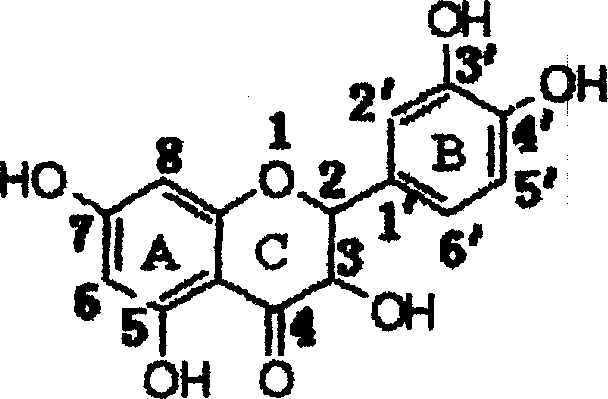

Method for extracting dihydro quercetin from larch using adsorption method

A technology of dihydroquercetin and larch, applied in organic chemistry and other directions, can solve problems such as low yield, and achieve the effects of reducing flammable hazards, good product stability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

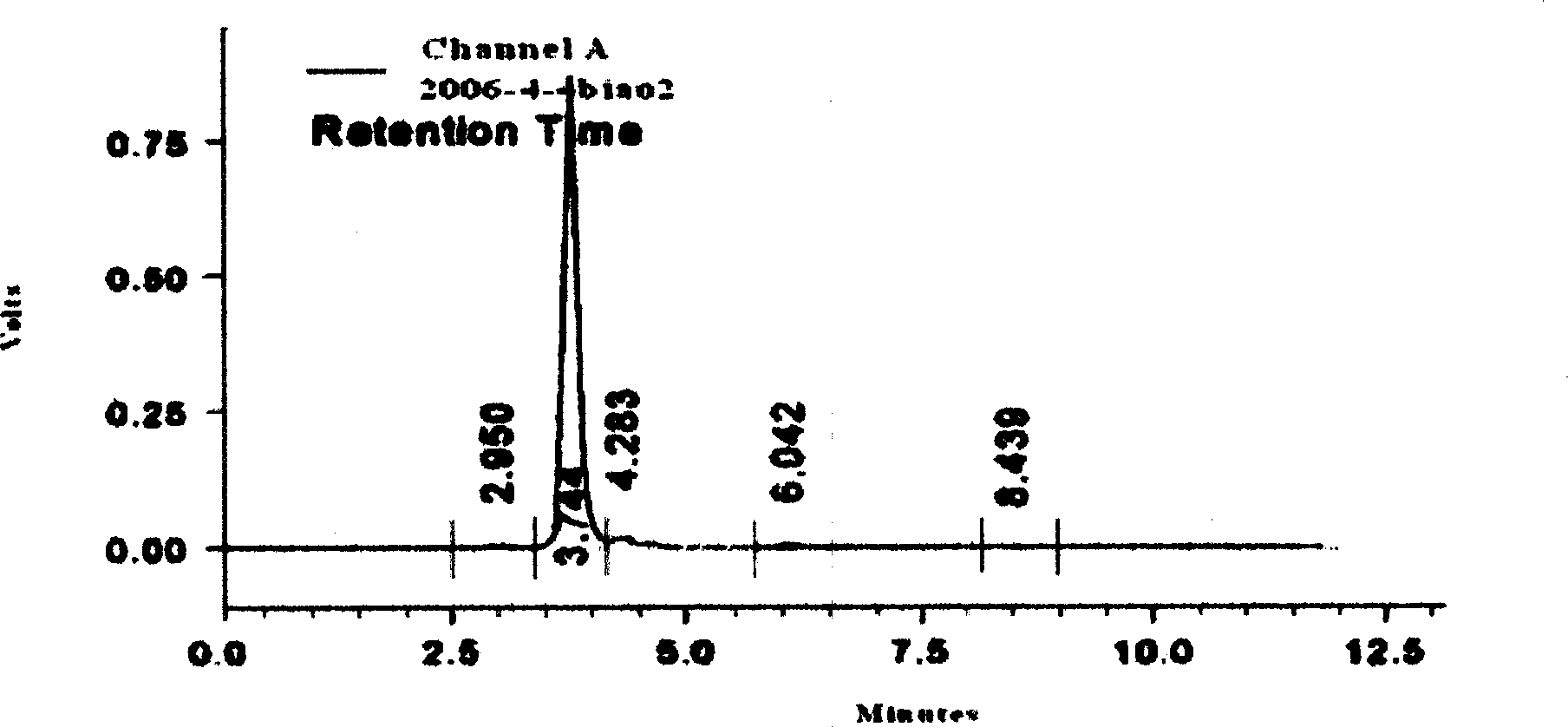

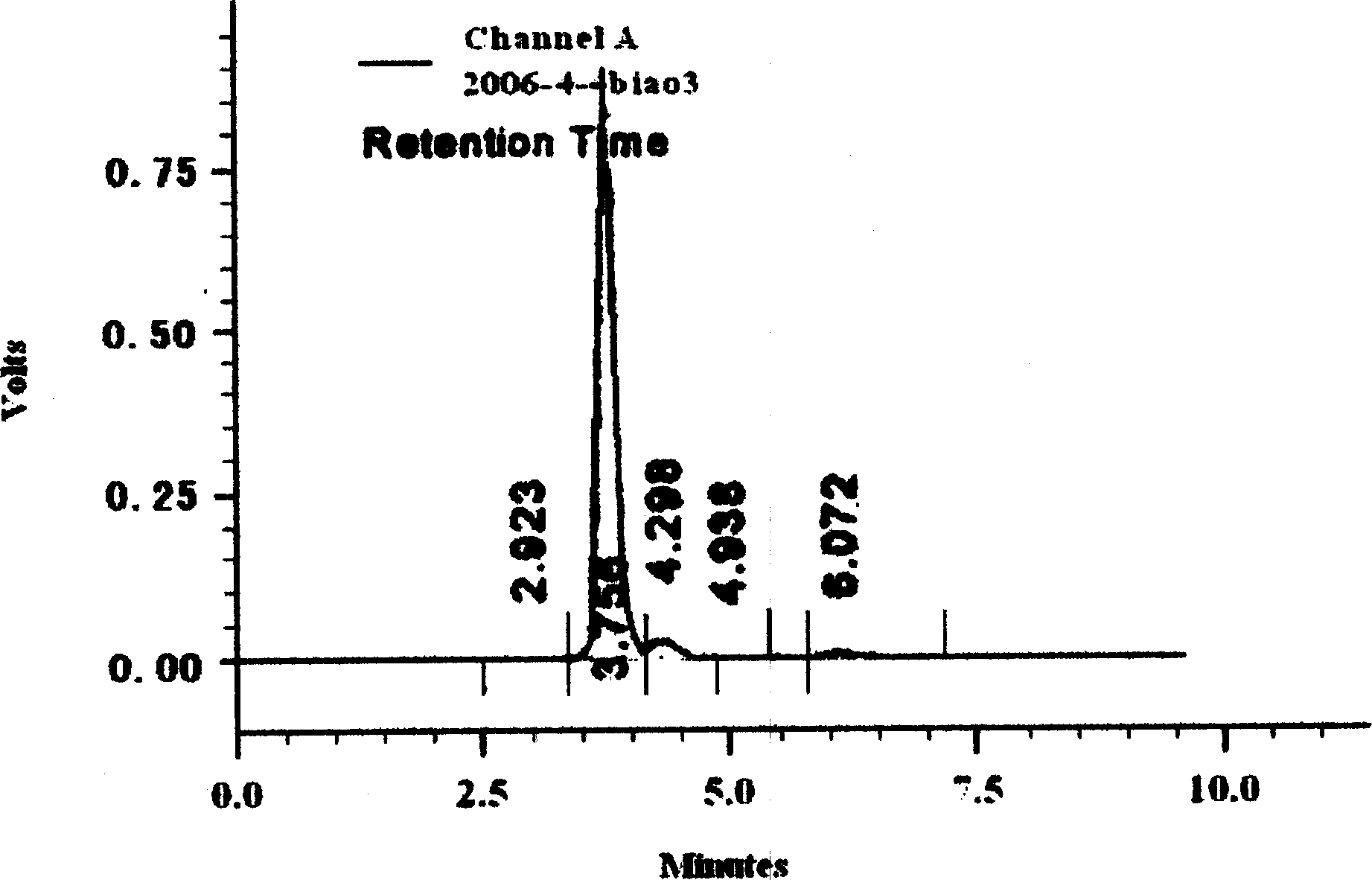

[0033] Take 1 kg of Xiaoxinganling larch sawdust from 0.0m to 1.5m above the ground and add it to a 4L stainless steel container, add 10L water (10 times water), soak at 85°C for 40 minutes, and separate to obtain an extract ( Extract I) 8.4L, the extract contains 0.11% dihydroquercetin. Then add 8.5L of 100°C water for the second time, soak at 87°C for 30 minutes, then use centrifugation to separate the sawdust and the secondary leaching solution to obtain 9.0L of the secondary extracting solution (extracting solution II), containing 0.028% dihydroquercetin, as a soaking solution for the next fresh larch sawdust.

[0034] In the state of stirring at 45°C, add 80g of activated carbon to the primary extract and stir for 30 minutes to decolorize. Add 0.10kg of 100-mesh polyamide powder to the filtered filtrate while stirring at 40°C, stir and absorb for 1.0 hour, and filter. After the polyamide powder is dried at room temperature, add 1.0 L of ethyl acetate, stir and desorb for...

Embodiment 2

[0039] Get the average thickness of the Daxing'anling larch tree section of 0.0m~1.5m tree section above the ground and be 0.3mm shavings 1kg, be placed in the stainless steel container that volume is 40L liters, add the secondary extraction solution II9.0L among the embodiment 1, in After soaking at 85°C for 60 minutes, 7.8 L of the primary extract was separated; 9.0 L of water was added to the filter residue for secondary extraction, and 9.0 kg of the secondary extract was obtained by filtration, which was used as the next soaking solution of fresh larch raw materials.

[0040]In the state of stirring, add 70g of activated carbon to the above-mentioned primary extract at 50°C and stir for decolorization for 30 minutes. Add 0.15kg of 60-mesh polyamide powder to the filtered filtrate while stirring at 40°C, stir and absorb for 1.5 hours, and filter. After the filtered polyamide powder is dried at room temperature, add 0.8 L of absolute ethanol, stir and desorb for 1.0 hour, and...

Embodiment 3

[0044] Use Daxinganling larch tree segments 0.0m~1.5m above the ground as raw materials, crush them into sawdust with an average particle size of 2×2×2mm, take 1kg of sawdust and put it in a stainless steel container with a volume of 40L, add 4.0L of the secondary extraction solution in Example 2 was soaked at 82°C for 60 minutes to obtain 3.1L of the primary extraction solution; 10L of water was added to the filter residue for secondary extraction for 1 hour, and the 10L secondary extraction solution obtained by filtration was obtained. Use as a soaking solution for your next fresh larch chipping.

[0045] In the state of stirring, add 30g of activated carbon to the above-mentioned primary extract at 45°C and stir for 30 minutes to decolorize. Add 0.062kg of 150-mesh polyamide powder to the filtered filtrate while stirring at 42°C, absorb under stirring for 1.0 hour, and filter Add 0.6L of acetone to the polyamide powder after drying at room temperature, stir and desorb for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com