Drum drying method

A drum drying and vacuum drying technology, which is used in the drying of solid materials, non-progressive dryers, heating to dry solid materials, etc., to shorten the drying cycle, enhance the flow, and strengthen the convective heat transfer process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

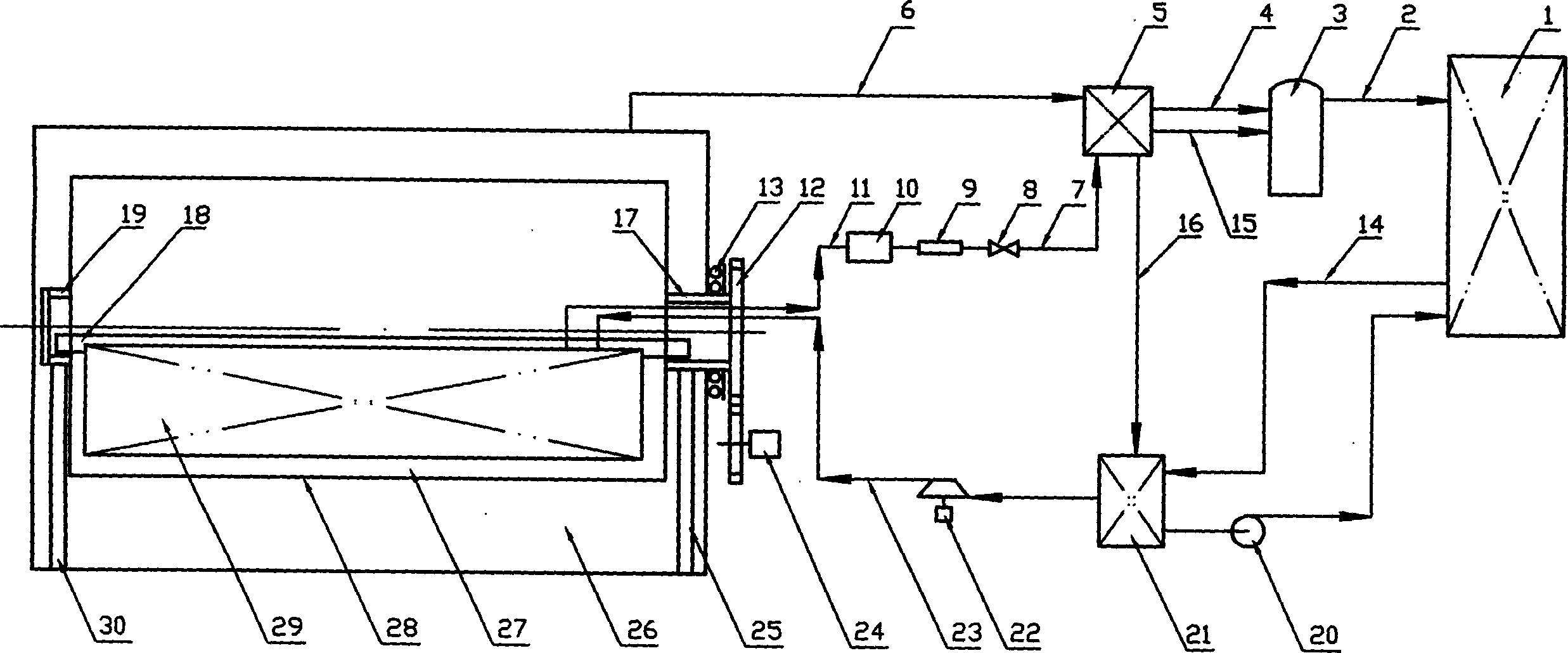

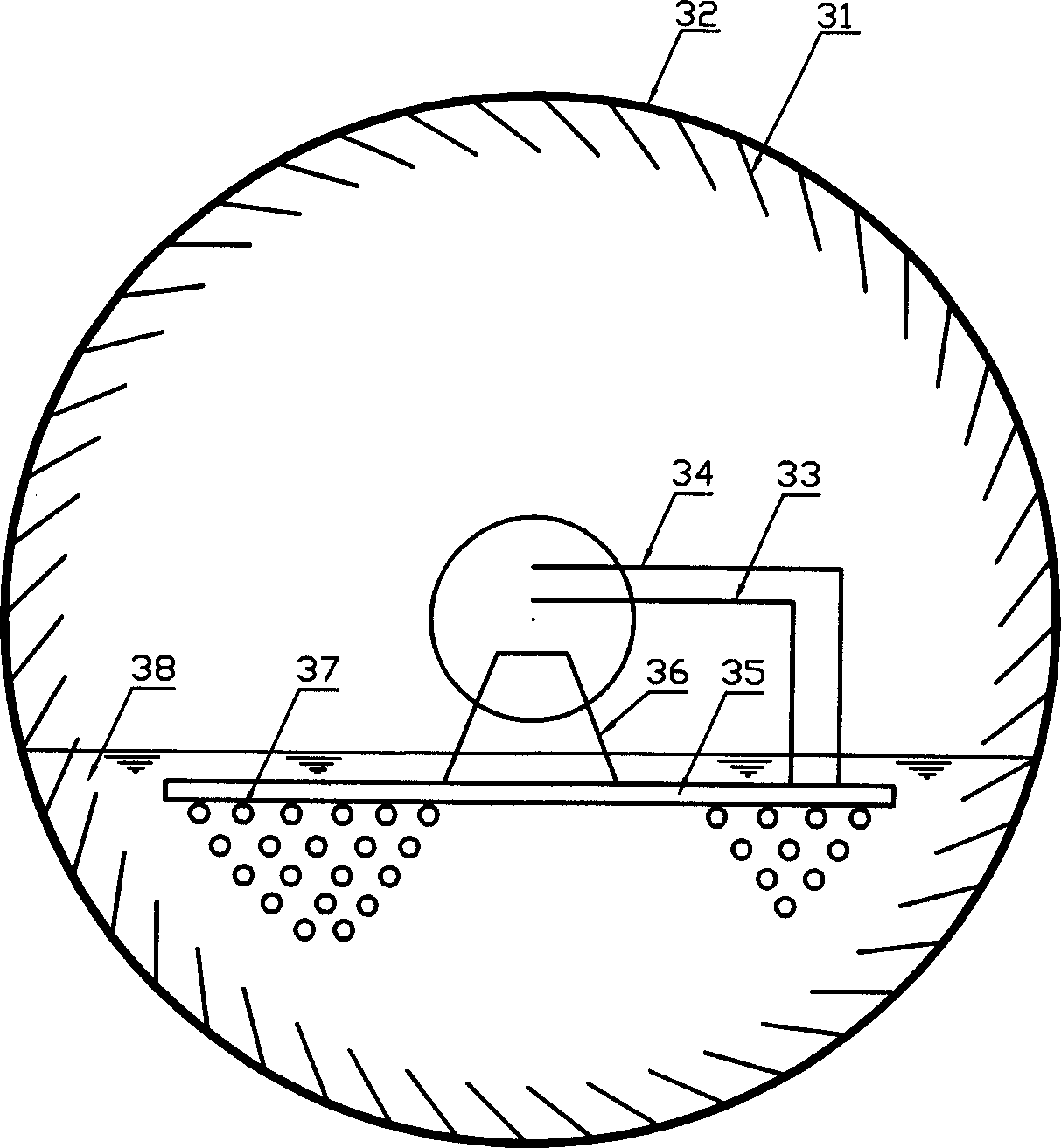

[0019] Embodiment 1: a kind of operating system that realizes the method of the present invention, mainly comprises the condenser 29 of the heat pump system in the drum 28, the liquid storage tank 10, the dry filter 9, the expansion valve 8, the water vapor condenser 5 and the vacuum system cooling A heat pump circulation subsystem composed of evaporators formed by water heat exchangers 21 connected in series; a vacuum pumping subsystem composed of a vacuum drying chamber 26, a water vapor condenser 5, a buffer tank 3, and a vacuum unit 1; the cooling water of the vacuum system The cooling water circulation subsystem composed of heat exchanger 21, water pump 20, vacuum unit cooling water return pipeline 14, vacuum unit 1, etc.; the drum rotation subsystem composed of deceleration system 24 and drum rolling gear system 12; the heat pump in the drum The system consists of condenser 29, drum 28, oil fins 32 inside the drum, heat pump system working fluid connection pipes 33, 34, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com