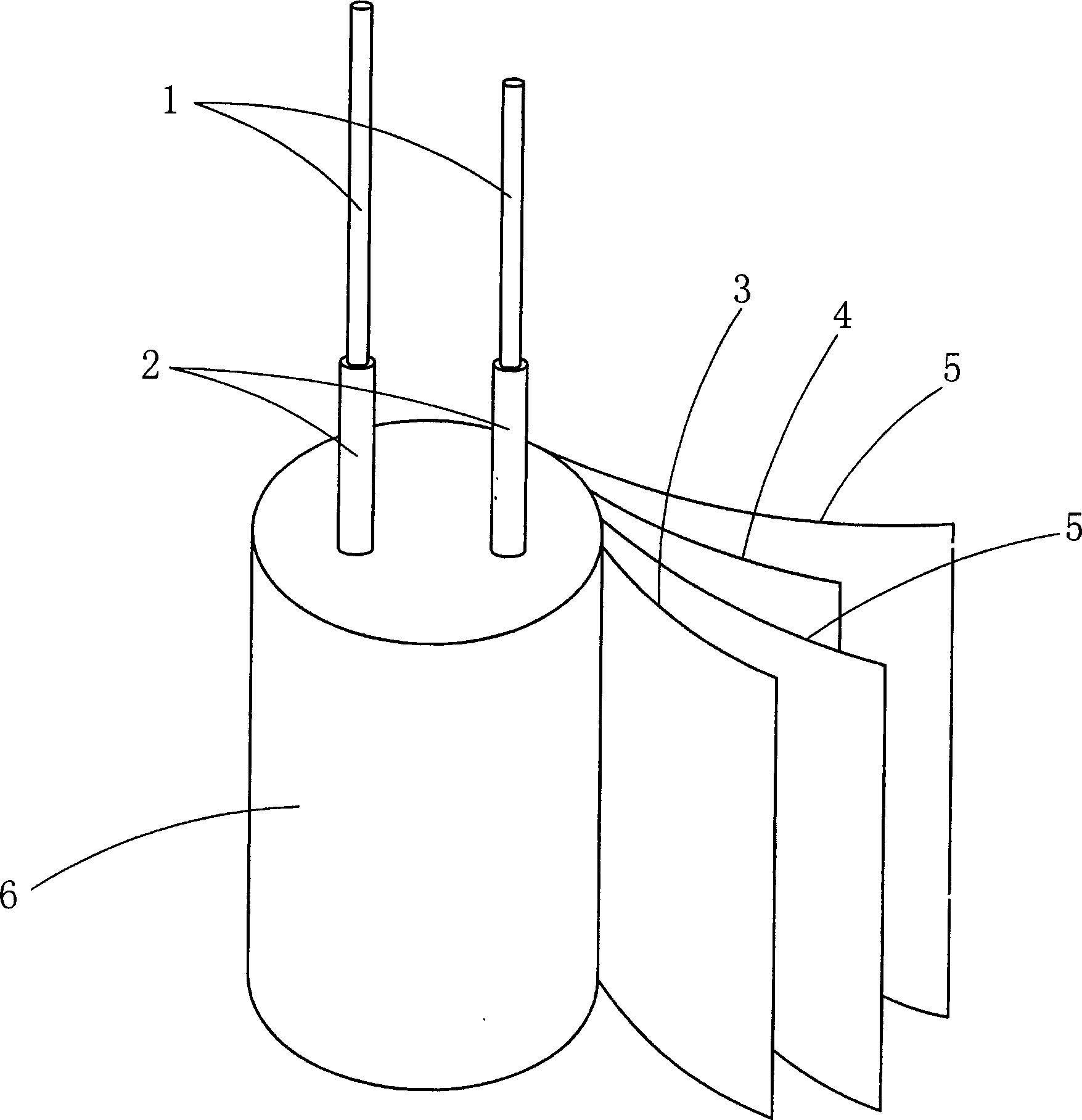

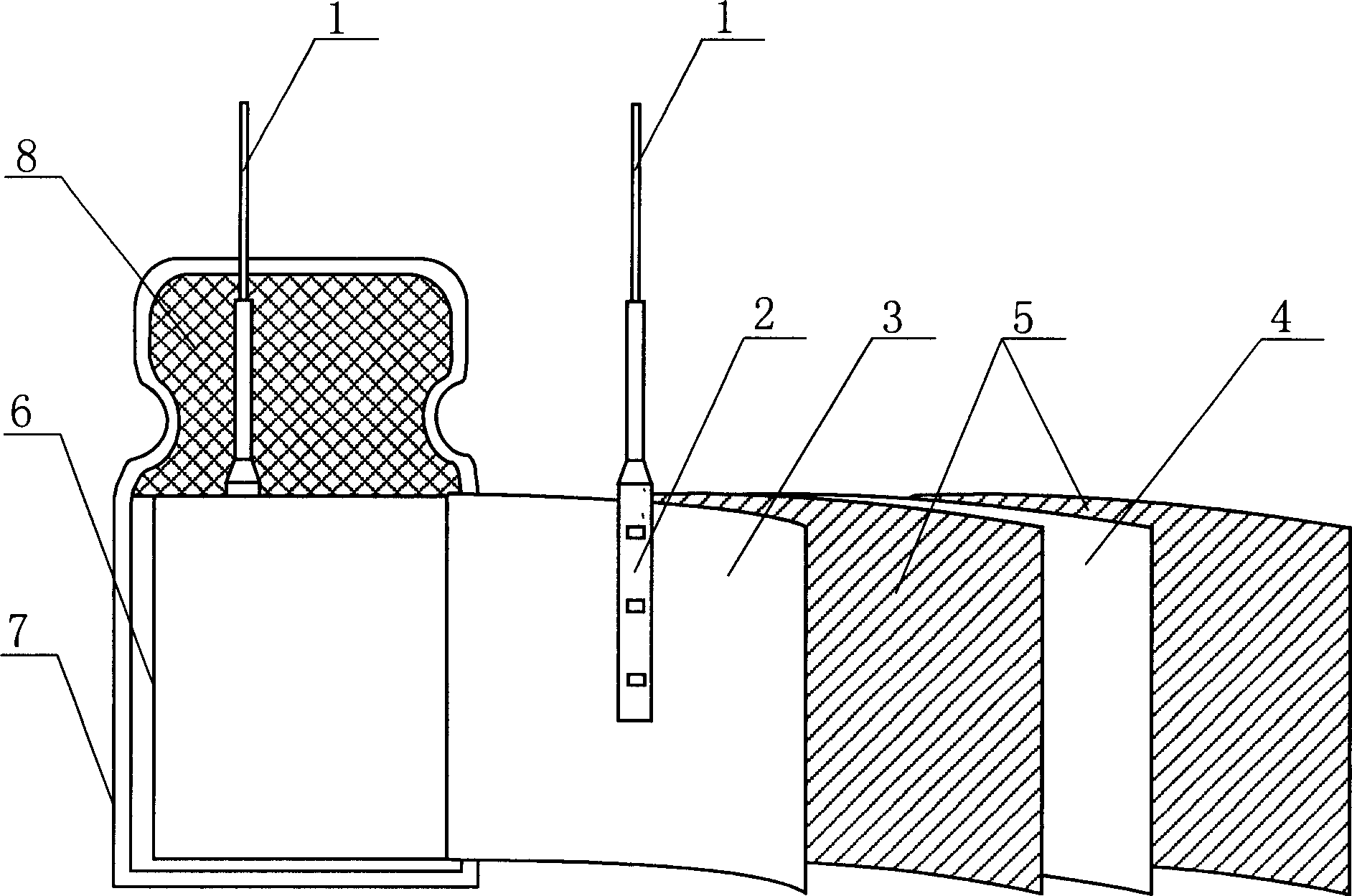

High-specific volume cathode foil solid electrolytic capacitor and preparing method thereof

A solid electrolysis and cathode foil technology, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of increasing impedance and ESR value, increasing impedance and ESR, and decreasing the degree of bonding, so as to reduce impedance and ESR value and achieve good results. Impedance frequency characteristics, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

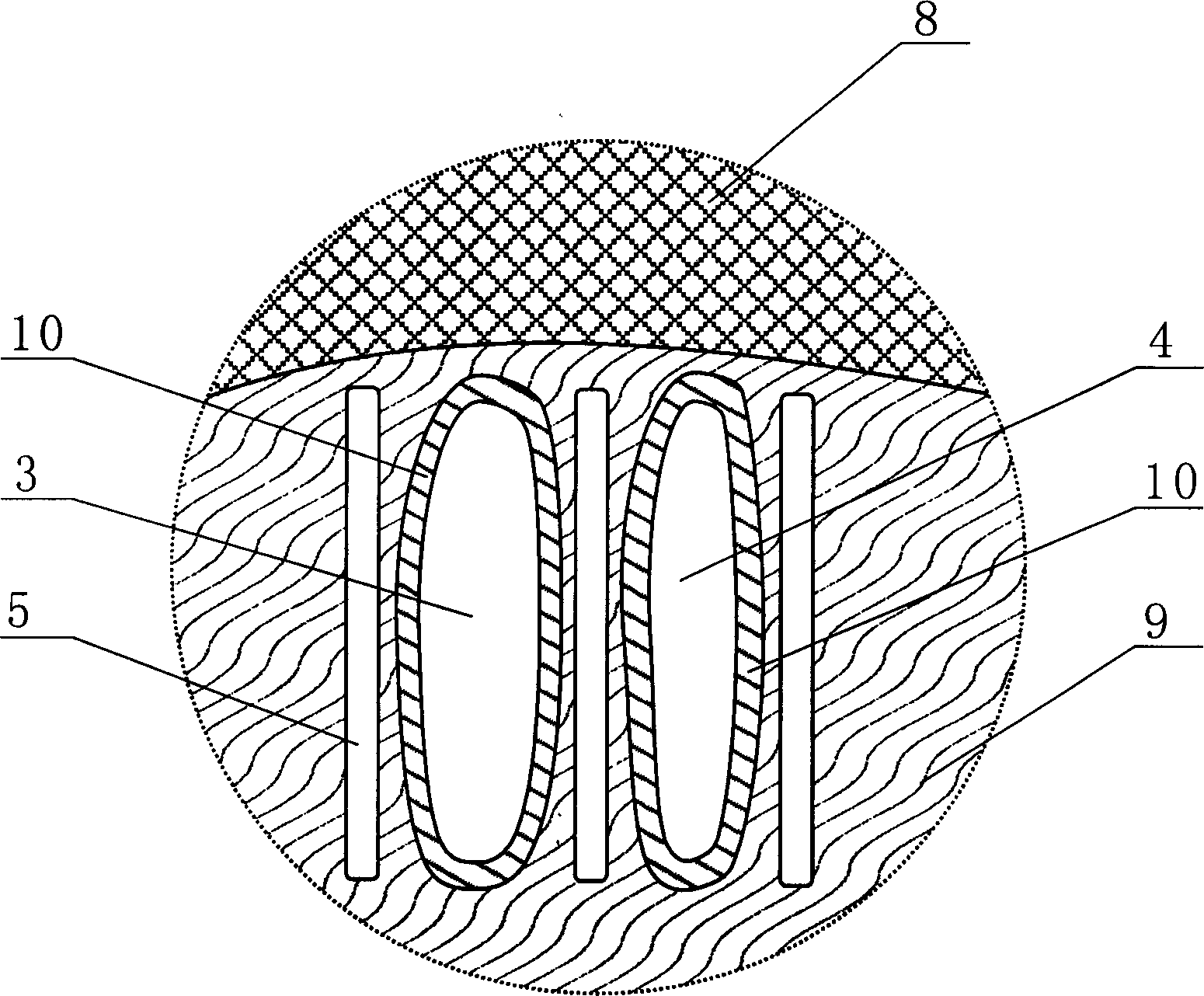

[0059] Embodiment 1: Select the high specific volume cathode foil of the present invention, the specific volume of the cathode foil is 2300 μF / cm 2 , and the rest are the same as Comparative Example 1.

Embodiment 2

[0061] Select the high specific volume cathode foil of the present invention, the specific volume of the cathode foil is 2300μF / cm 2 , insert electrolytic paper containing Manila hemp fiber between the anode aluminum foil and the cathode aluminum foil, the paper density is 0.4 g / cm 3 , with a thickness of 40 μm, they are rolled up to form a coiled capacitor core. At a temperature of 85 ° C, the capacitor core is oxidized with a 7% ammonium adipate solution for 30 minutes, and then baked at 220 ° C for 90 minutes to make The electrolytic paper is completely carbonized, and the carbonized capacitor core is immersed in a solution of iron toluenesulfonate n-butanol containing 3% to 5% of 3.4-ethylenedioxythiophene (EDT) for 30 minutes at 20-30°C and a vacuum below 20mmHg Carry out chemical oxidative polymerization. The following steps are the same as in Example 1 to prepare a solid electrolytic capacitor.

[0062] According to Comparative Example 1, the initial characteristics a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com