Preparation method of initiating solvent for direct liquefy of coal

A technology of direct coal liquefaction and solvent, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry. It can solve the problems of difficult to meet the requirements and low output, and achieve good hydrogenation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

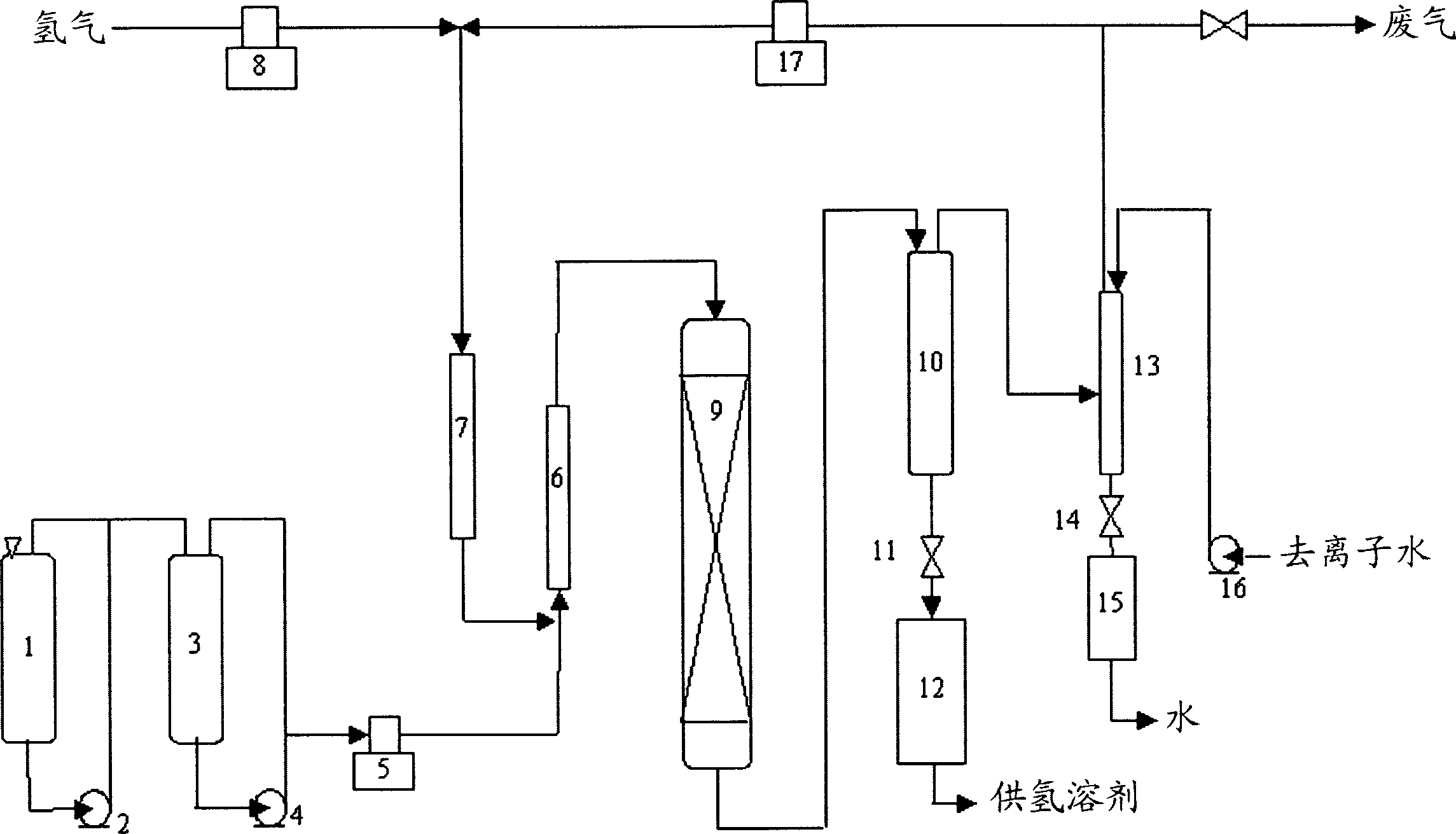

[0020] The method provided by the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

[0021] Such as figure 1 Shown, the petroleum distillate as raw material is at first mixed with vulcanizing agent dimethyl disulfide (DMDS) in raw material configuration tank 1, and the ratio that it mixes is 1.5wt% of raw material, is delivered to metering by low-pressure circulating pump 2 then Tank 3, and sent to the raw material preheater 6 through the low-pressure circulation pump 4 and high-pressure circulation pump 5 for preheating; after the hydrogen is boosted and preheated by the hydrogen compressor 8 and the hydrogen preheater 7, it enters together with the raw material Raw material preheater 6; the temperature of the material at the outlet of the preheater is generally about 200°C; the raw material enters from the top of the fixed-bed hydrogenation reactor 9 together with hydrogen for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com