Thermal analysis method for determining silicane mixture content

A mixture and thermal analysis technology, which is applied in the field of thermal analysis and detection, can solve the problems of reduced service life, many pores, and low accuracy, and achieve the effect of convenient and fast method, accurate measurement and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, measure the thermal analysis method of silane mixture content,

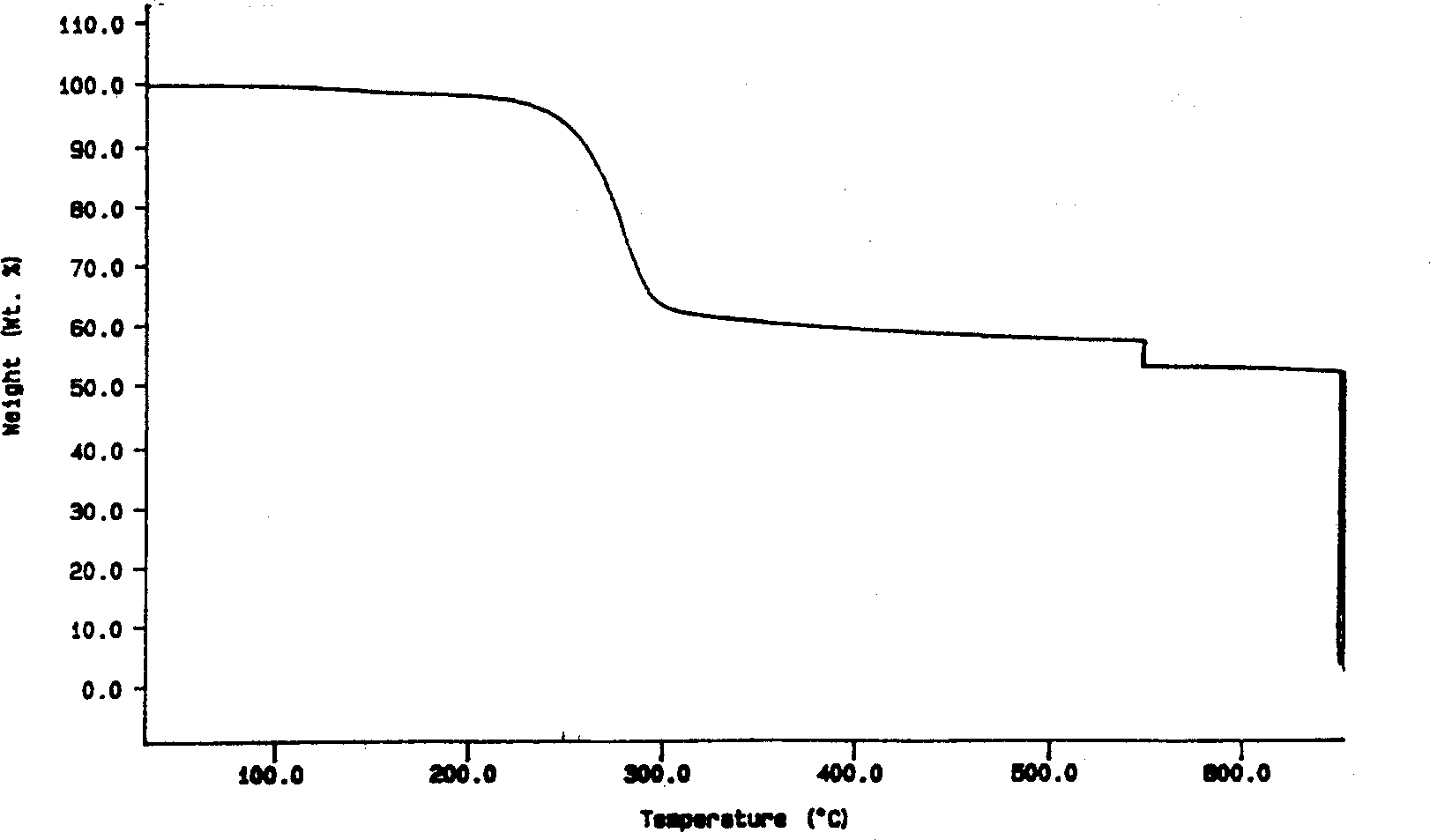

[0035] The instrument adopts the 7 series thermogravimetric analyzer produced by the American PE company, and takes 8.539 mg of imported silane mixture sample and 8.417 mg of domestic sample, and the flow rates of nitrogen and oxygen are both: 40ml / min.

[0036] Selection of sample dosage: take 5-10 mg sample and place it in an aluminum oxide sample dish;

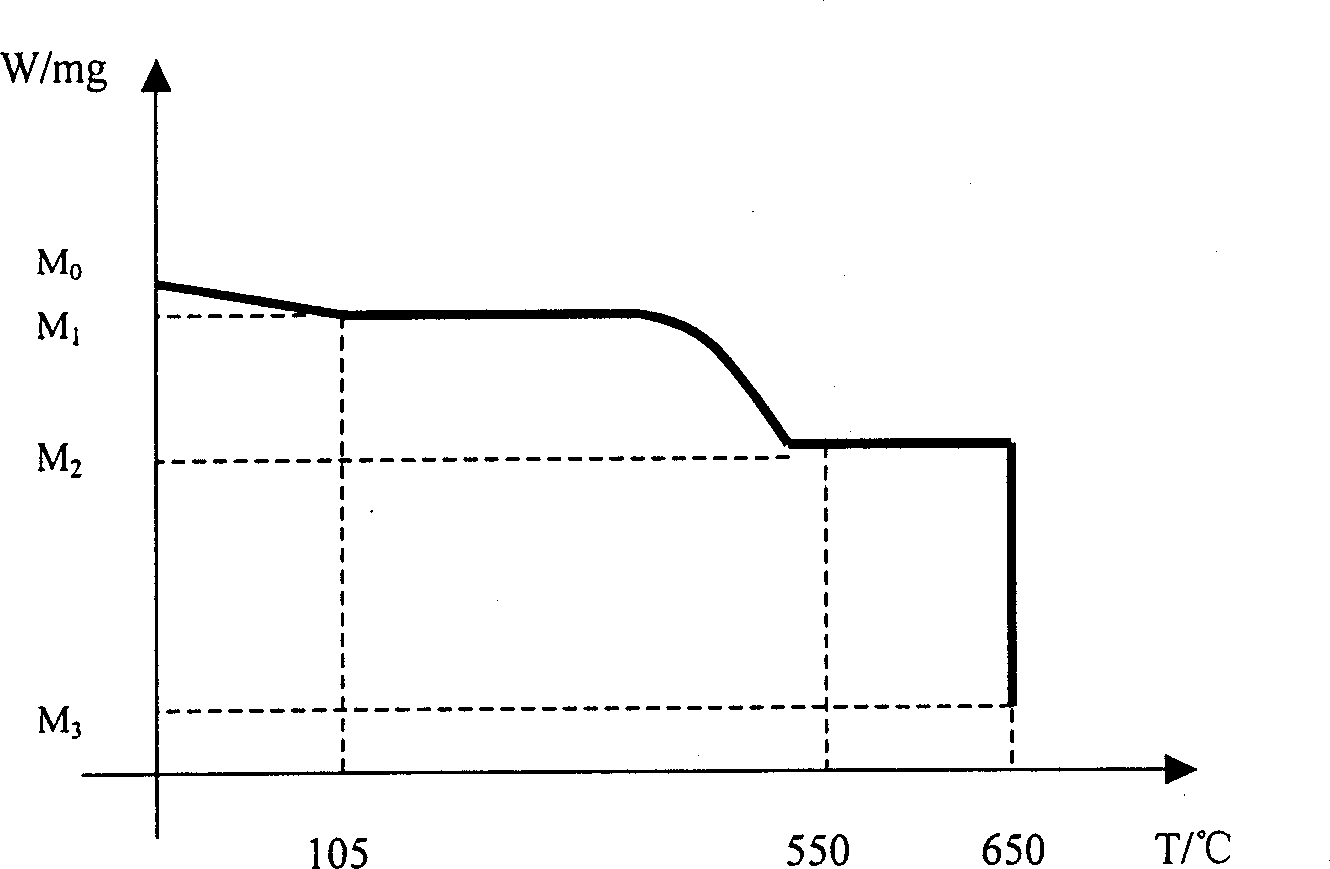

[0037] Program design: heating from room temperature to 550°C at a rate of 10°C / min in nitrogen atmosphere; isothermal at 550°C for 60 minutes; heating to 650°C at a rate of 10°C / min; changing gas from nitrogen to oxygen ; Isothermal at 650°C for another 60 minutes.

[0038] Selection of atmosphere: the flow rates of nitrogen and oxygen are both: 40ml / min.

[0039] Calculated by thermogravimetric curves: curves such as figure 1 As shown, from the thermogravimetric curve, heating from room temperature to 550°C at a rate of 10°C / min in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com