Three-D nanoporous polymer film and its manufacturing method

A polymer film, three-dimensional nanotechnology, applied in optics, instruments, optical components, etc., can solve the problems of poor mechanical strength and oil resistance of anti-reflection films, and achieve the effect of avoiding glare or interference from reflected light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Take a reaction bottle, put 8g (26.82mmol) pentaerythritol triacrylate into the bottle as a multifunctional reactive resin, and dissolve it with 10g tetrahydrofuran (tetrahydrofuran; THF) at a room temperature of 25°C. The ratio is 8wt%. Next, 3.43 g of nematic liquid crystal (nematic liquid crystal, purchased from Merck, code number E7) was added as a template material. After stirring until dissolved, 0.24 g of triphenyl trifluoromethanesulfonate (triphenyl triflate) was added as a photoinitiator, and the preparation of the three-dimensional nanoporous polymer coating composition (A) was completed so far, wherein the resin and the template material The weight ratio is 7:3, and the viscosity of pentaerythritol triacrylate in the three-dimensional nanoporous polymer coating composition (A) is 520 CPS / 25°C. Next, the three-dimensional nanoporous polymer coating composition (A) was coated on a glass substrate with a spin coater, and the rotation speed was controlled at 25...

Embodiment 2

[0099] Proceed in the same manner as Example 1, but reduce the amount of pentaerythritol triacrylate described in Example 1 to 5.6 g, and add 2.4 g of urethane acrylate, so that the polyfunctional The weight ratio of the force resin to the bifunctional acrylic resin is 7 / 3.

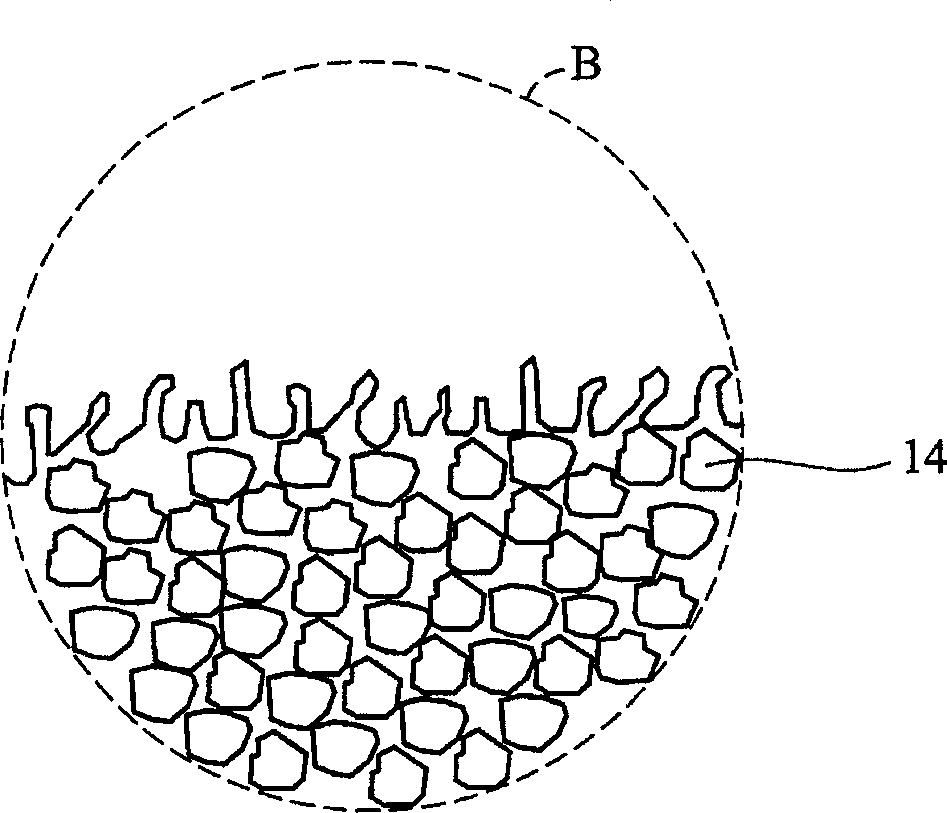

[0100] Please refer to image 3 Shown is the SEM image of the three-dimensional nanoporous polymer film formed in Example 2 under the observation of a scanning electron microscope (Scanning Electron Microscope, SEM, model HITACHI S-4200).

Embodiment 3

[0102] Proceed in the same manner as in Example 1, but reduce the amount of pentaerythritol triacrylate described in Example 1 to 4 g, and add 4 g of urethane acrylate, so that the polyfunctional acrylic resin The weight ratio to the bifunctional acrylic resin is 1 / 1.

[0103] Please refer to Figure 5 Shown is the SEM image of the three-dimensional nanoporous polymer film formed in Example 3 under the observation of a scanning electron microscope (Scanning Electron Microscope, SEM, model HITACHI S-4200).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com