Laser and its manufacturing method

A manufacturing method and laser technology, applied to lasers, laser components, semiconductor lasers, etc., can solve the problems of inability to change the shape of the mode field, increase the packaging cost, and mismatch of the mode field, so as to reduce the divergence angle of the far field and increase the Effect of high output power and reduced power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

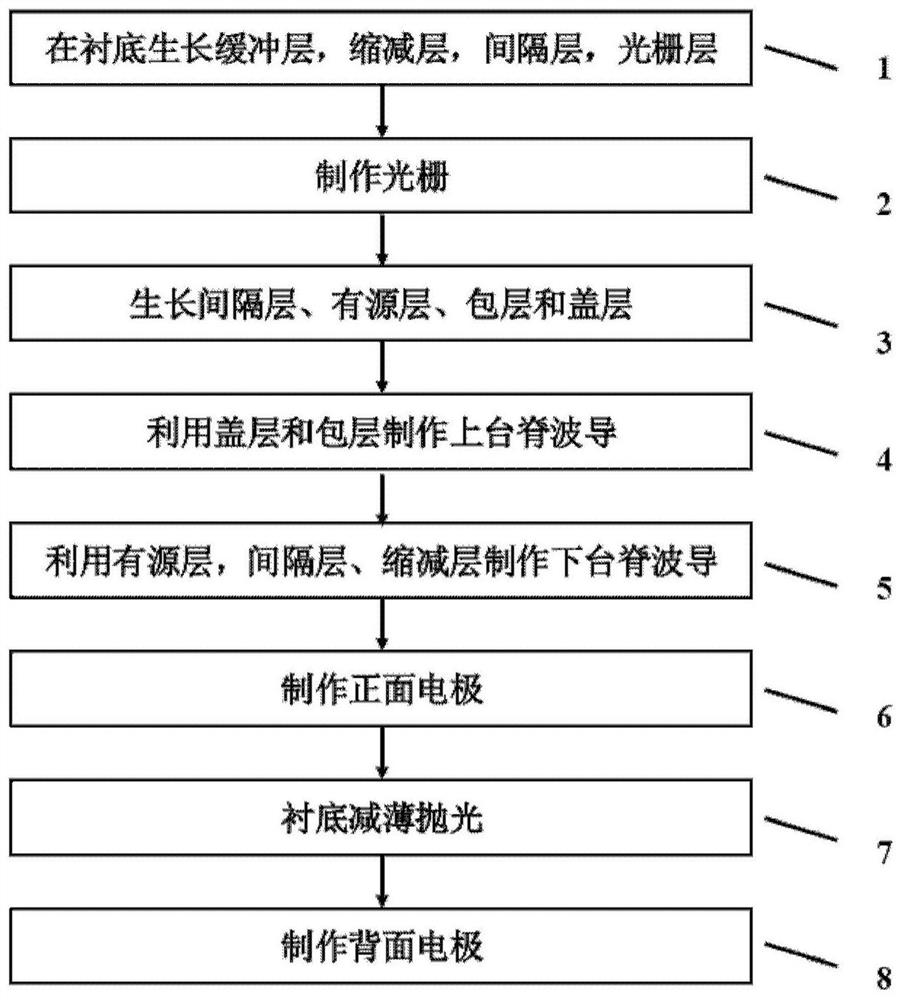

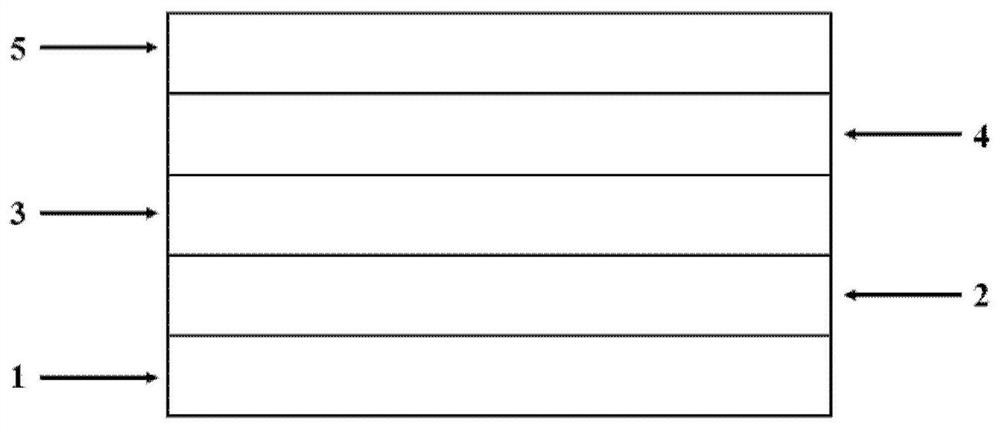

[0065] figure 1 It is a schematic flow chart of the laser manufacturing method in Embodiment 1 of the present invention. Such as figure 1 As shown, step 1: using Metal-organic Chemical Vapor Deposition (MOCVD) to sequentially epitaxially grow an n-type InP buffer layer 2 with a thickness of 500-1000 nm on an n-type InP substrate 1, and a light spot magnification layer 3, 20 ~50nm thick InP spacer layer 4, 30nm thick InGaAsP grating layer 5, such as figure 2 ;

[0066] Wherein, the spot enlargement layer 3 is a far-field reduction layer formed of an InGaAsP layer with a thickness of 40-60 nm;

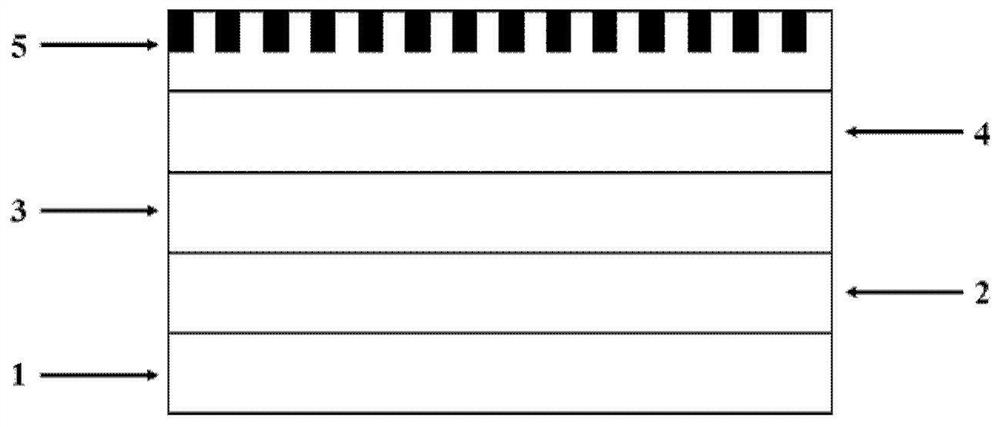

[0067] Step 2: Use holographic exposure technology and dry etching technology to make a large-area grating on the InGaAsP grating layer 5; use holographic exposure to make a uniform grating, and use Reactive Ion Etching (RIE) to etch the grating layer. Soak in grating bromine to repair damage caused by RIE etching, such as image 3 ;

[0068] Step 3: Secondary epitaxial growth of ...

Embodiment 2

[0075] The manufacturing method of this embodiment 2 is the same as that of embodiment 1, the difference is that the light spot amplification layer 3 of this embodiment 2 is a diluted waveguide layer, and a 60nm-thick InGaAsP layer and a 300nm-thick InP layer are alternately grown for 3 to 5 cycles form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com