Nucleocapsid catalyst in use for fuel cell and preparation method

A core-shell catalyst and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as high equipment requirements, not suitable for mass production, and limited number of functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

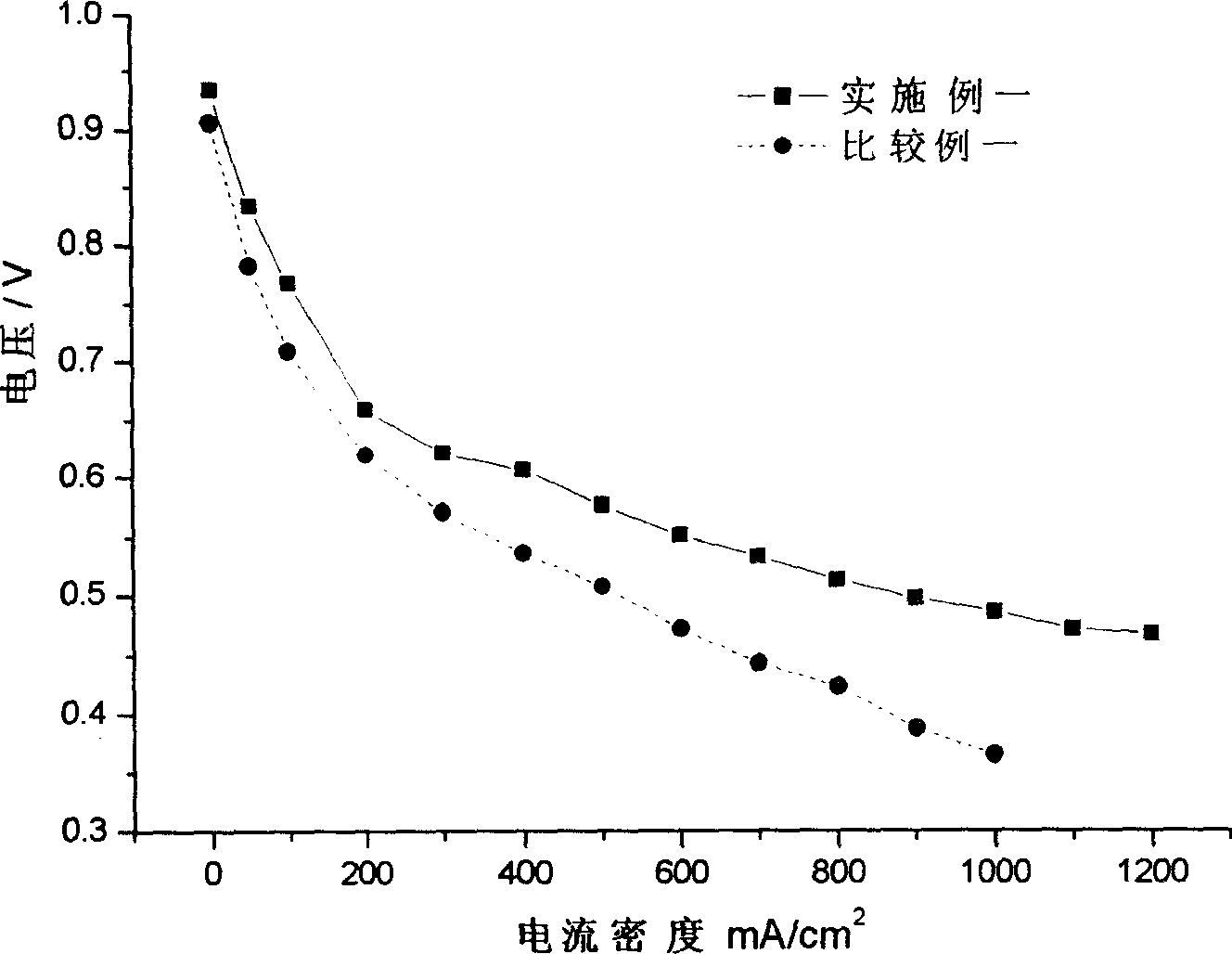

Embodiment 1

[0035] Take 500 ml of 0.05 mol / liter polydiallyldimethylammonium chloride, add 500 ml of 0.02 mol / liter nickel chloride solution, and stir for 3 minutes with an electric motor at a speed of 300 rpm. Add 0.1 mol / L NaBH 4 15 ml, stirred for 5 minutes, and passed through H 2 Protect. Add 0.01 mol / L H 2 PtCl 6 100 ml of the solution was stirred electrically for 1 hour at 500 rpm. Add 0.29 g of VulcanXC-72 carbon powder, electric stirring for 15 hours at 5000 rpm, filter and rinse with deionized water for 5 times, and vacuum dry at 80°C. The mass ratio of carbon to platinum in the prepared carbon-supported [nickel] (platinum) catalyst (the elements in the square brackets represent the core of the core-shell structure, and the elements in the brackets represent the shell of the core-shell structure) is 3:2. The transmission electron microscope image of the catalyst is shown in figure 2 .

Embodiment 2

[0041] Take 500 ml of 0.02 mol / L sodium citrate, add 500 ml of 0.01 mol / L cobalt chloride solution, and stir electrically for 5 minutes at a speed of 500 rpm. Add 0.1 mol / L NaBH 4 15 ml, stirred for 5 minutes, and passed through H 2 Protect. Add 0.01 mol / L H 2 PtCl 6 The solution was 100 ml, stirred by electric motor for 1 hour at 500 rpm, filtered and rinsed with deionized water 5 times, and dried under vacuum at 60°C. The prepared [cobalt] (platinum) catalyst. The transmission electron microscope image of the catalyst is shown in image 3

Embodiment 3

[0043] Take 500 ml of 0.04 mol / L sodium dodecylsulfonate solution, add 500 ml of 0.01 mol / L ferric sulfate solution, and stir for 4 minutes with a rotating speed of 400 rpm. Add 0.1 mol / L N 2 H 2 ·H 2 O40 ml, stirred for 5 minutes, and passed into H 2 Protect. Add 0.01 mol / L RuCl 3 100 ml of the solution was stirred electrically for 1 hour at 500 rpm. Add 0.404 g of VulcanXC-72 carbon powder, electric stirring for 15 hours at 5000 rpm, filter and rinse with deionized water for 5 times, and vacuum dry at 80°C. The mass ratio of carbon to ruthenium in the prepared carbon-supported [iron] (ruthenium) catalyst is 4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com