Removal method and equipment for sucking ammonia nitrogen in waste water through negative pressure of vacuum

A technology of vacuum negative pressure and vacuum suction, applied in the field of water treatment, can solve the problems of high corrosion resistance and high temperature and high pressure requirements, consumption of large chemicals or energy, impossible ammonia removal method, etc., achieving strong practicability and easy promotion. , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

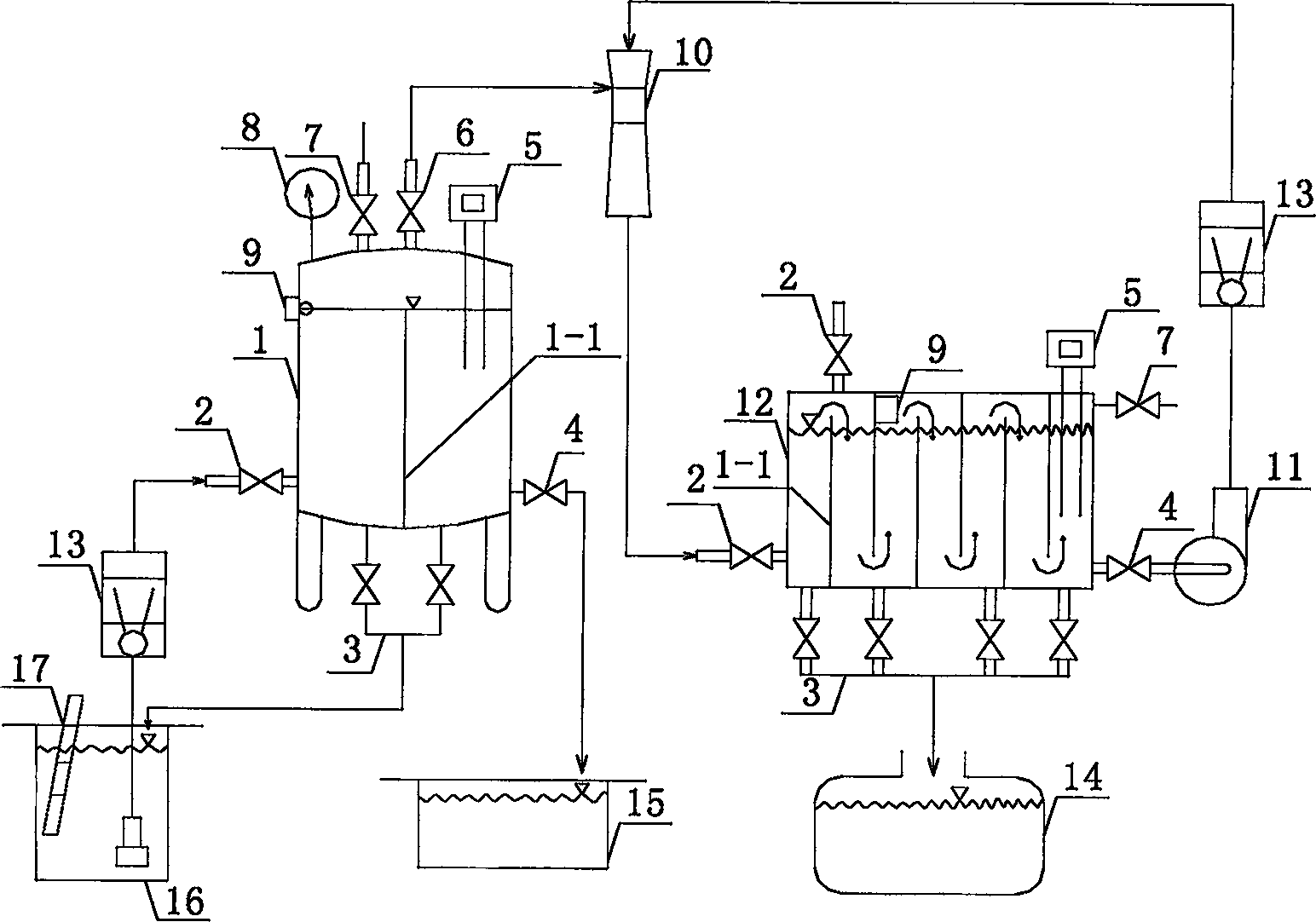

[0068] Example 1. One of the vacuum negative pressure suction denitrification equipment that can be both sequential batch and continuous operation:

[0069] This device combination is typical and simplest, and its structure is as figure 1 As shown: it consists of three parts: vacuum denitrification tank 1, water jet vacuum pump (including water jet 10 and supporting water pump 11) and churning type gas absorption tank 12. The vacuum denitrification tank 1 and the tumbling gas absorption tank 12 are provided with 1 to 60 water flow partitions 1-1 in the tank, or depending on the volume of the vacuum denitrification tank 1 and the tumbling gas absorption tank 12, the water flow The number of baffles increases as the volume increases; if two or more water flow baffles 1-1 are provided, these water flow baffles are arranged in parallel up and down in the tank. Numbers 13 and 14 in the figure are liquid flow meter and ammonia water storage tank respectively.

[0070] The first ty...

example 2

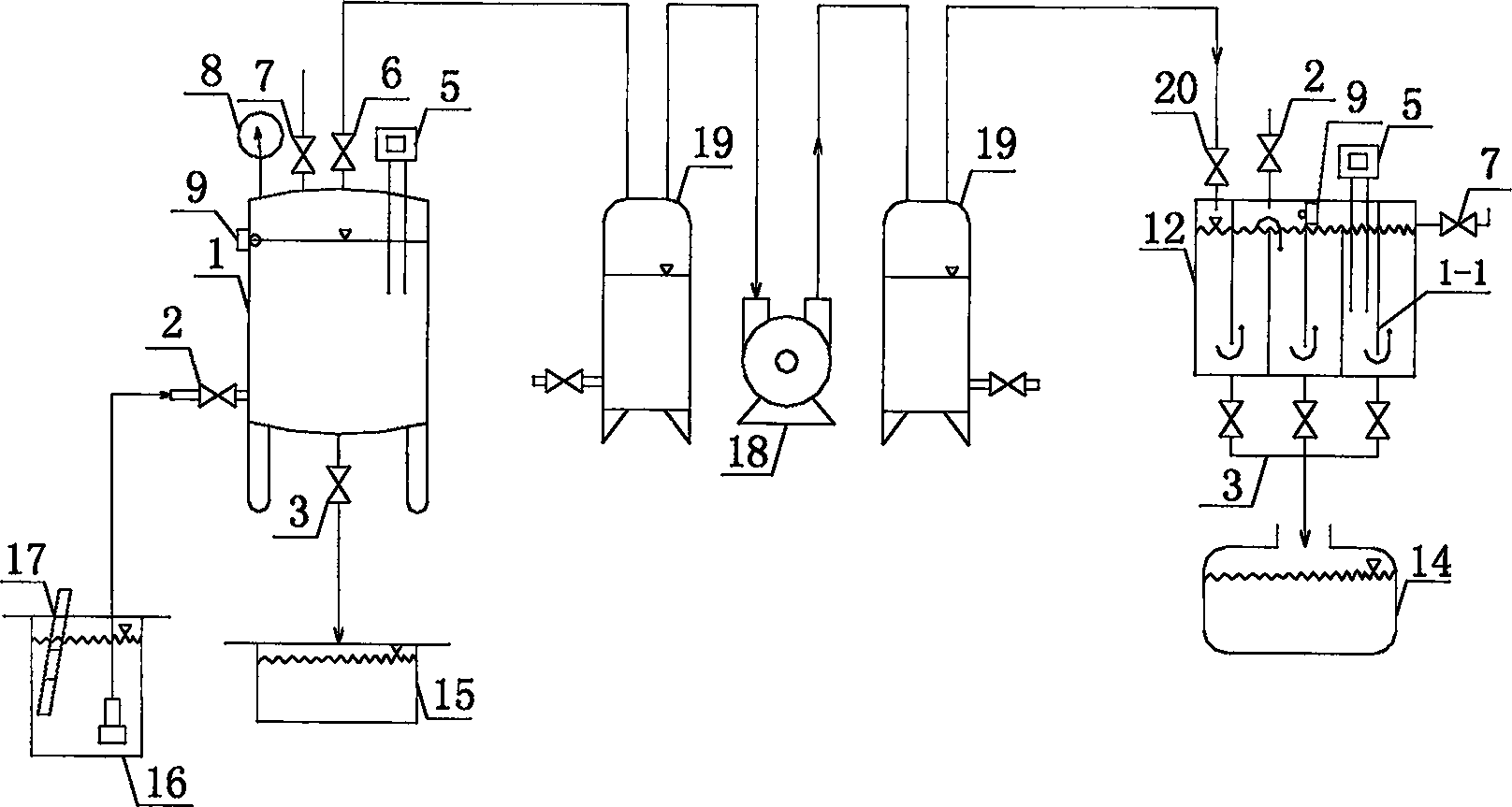

[0074] Example 2. Vacuum negative pressure suction denitrification equipment that can be both sequential batch and continuous operation:

[0075] The structure of this device is as image 3 Shown: Adopt Venturi gas absorption tower 21 to replace figure 1 The churning type gas absorbing tank 12 in adopts water ring type or rotary vane vacuum pump 18 to replace figure 1 water jet vacuum pump. Serial number 22 and 23 among the figure are circulating water tank, circulating water pump respectively. Apart from this, other components including the connection relationship are the same as the first example.

[0076] This equipment carries out vacuum denitrification treatment. The scale of its processing equipment is a continuous flow rate of 4L / h, and the processing time is 1h. The results in Attached Table III can be obtained under different vacuum negative pressures. Compared with Example 1, the denitrification and ammonia regeneration effect of this equipment is slightly worse...

example 3

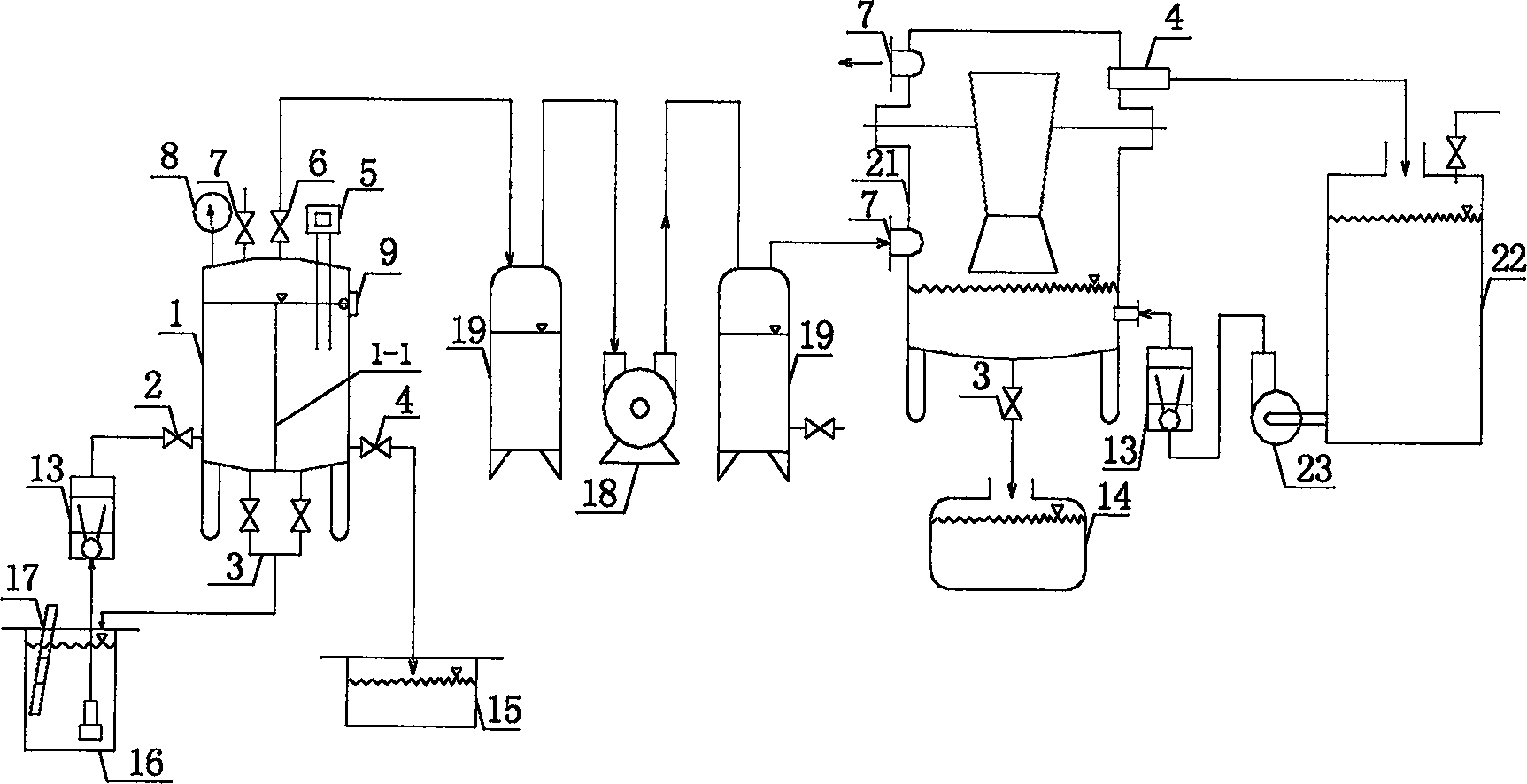

[0077] Example 3. The third of the vacuum negative pressure suction denitrification equipment that can be sequenced batch type and can be operated continuously:

[0078] The structure of this device is as Figure 4 As shown: a multi-baffle tumbling vacuum denitrification tank 1 and two tumbling gas absorption tanks 12 (referred to as absorption tanks) are used, and the inner cavity is equipped with a plurality of evenly staggered parallel pipes along the vertical direction of the water inlet and outlet valves. Arranged waterproof current short-circuit partitions, this example is designed as six partitions.

[0079] The connection mode between the jet vacuum suction system of the device and the vacuum denitrification tank 1 and the tumbling gas absorption tank 12 is basically the same as that of the example 1, except that a tumbling gas absorption tank 12 is added. Because a tumbling gas absorption tank 12 is added, the water jet vacuum pump realizes switching between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com